Are you sourcing stamped components and finding the cost estimates overwhelming? At Topmetalstamping, we understand how critical accurate budgeting is for OEM service partners and manufacturers alike. Between material choices, tooling design, press operations, and supplier mark‑ups, it can feel like a maze. In this blog, we’ll demystify every major cost driver in a metal stamping project—from raw materials to die construction—so you can partner more effectively with your suppliers and optimize your budget from prototype through high‑volume production.

Key Factors That Drive Metal Stamping Costs

When stamping sheet metal parts, job shops and suppliers calculate costs by considering:

- Raw Material Consumption

- Press Time & Equipment Overhead

- Tooling and Die Fabrication

- Labor and Secondary Operations

- Quality Assurance and Scrap Allowance

Let’s explore each in detail.

1. Raw Material Costs: The Foundation of Every Quote

Sheet Metal Gauge & Yield:

- Thicker gauges cost more per square foot and require greater forming force.

- Excess scrap is inevitable in stamping; raw material consumption often exceeds finished part weight by 10–25%.

Material Selection:

- Aluminum 1100, 3003, 5052: Lightweight, good formability; popular for enclosures and heat sinks.

- Stainless Steel (304, 316L, 430): Excellent corrosion resistance; ideal for medical, food, and outdoor applications.

- Carbon Steel & HSLA: Economical and strong; widely used in automotive brackets and structural parts.

Tip: When negotiating OEM service contracts, review your supplier’s scrap allowance assumptions. A well‑engineered nest can reduce scrap by up to 15%, saving significant material costs over large runs.

2. Press Time and Equipment Overhead

Machine Hourly Rates:

Suppliers determine press rates by factoring in depreciation, maintenance, energy, and floor space. For example, a 250‑ton mechanical press might run $75–$120 per hour; a 1,000‑ton servo‑hydraulic press could exceed $200 per hour.

Cycle Time (SPM):

- Manual Single Process: 5–10 strokes per minute (SPM), suitable for low volumes (<100,000 parts).

- Automated Progressive Dies: 100–300 SPM, ideal for high‑volume, multi‑stage forming.

Tip: Match your stamping process to your volume. If your orders exceed 200,000 pieces per year, progressive or transfer dies on a high‑speed press will drastically lower per‑part press time costs.

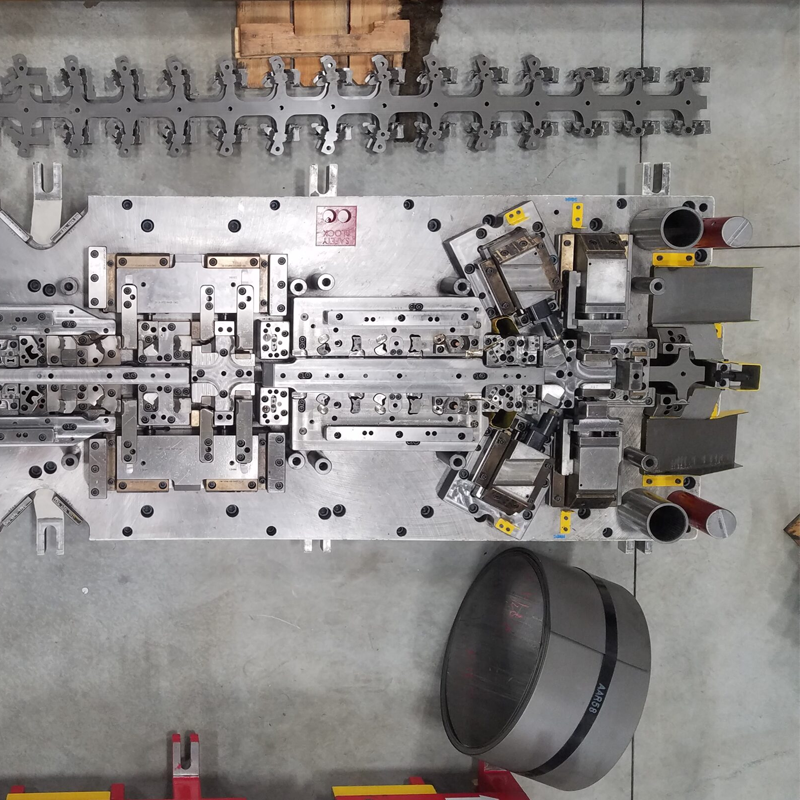

3. Tooling & Die Fabrication: The Capital Investment

Die Material Costs:

- Blank and lower die components are typically made from P20 or H13 tool steel, priced around $5–$7 per pound.

- A simple single‑station die (400 mm x 1,000 mm) may use 100–150 lbs of steel per platen.

Tooling Multipliers:

- Single‑Operation Dies: Die material cost × 3 → base price covering design, machining, heat treat, and assembly.

- Progressive Dies: Die material cost × 6–8 → additional stations, lifters, and automation features.

Engineering & Prototyping:

- Finite‑Element Analysis (FEA) and small‑batch prototyping can uncover forming issues—often saving more in rework than they cost.

Tip: Ask your stamping supplier about their in‑house tooling shop versus external toolmakers. In‑house die builders (like Topmetalstamping) often pass lower tooling rates to OEM service customers due to streamlined workflows.

4. Labor, Secondary Operations & OverheadLabor Costs:

- Manual loading/unloading, maintenance, and die setup add to per‑part labor rates.

- Automated lines reduce operator headcount but increase upfront capital.

Secondary Processes:

- Piercing, tapping, bending, welding, coating, and assembly all add time and cost.

- Some suppliers bundle these as turnkey solutions; others itemize them separately.

Tip: Consolidating downstream operations with your metal stamper can yield volume discounts and reduce logistics complexity. Consider suppliers who offer end‑to‑end OEM services.

5. Quality Assurance & Scrap Management

Inspection & Testing:

- Coordinate Measuring Machine (CMM) checks, vision systems, and SPC charting ensure parts meet tight tolerances.

- Suppliers often include a scrap percentage—typically 2–5%—to cover initial setup runs and process variation.

Traceability Requirements:

- Automotive and aerospace OEMs demand full material and process traceability (IATF 16949, AS9102).

- Additional documentation raises supplier overhead, so negotiate quality levels aligned with your application’s risk profile.

Tip: If your application can tolerate broader tolerances or fewer inspection steps, discuss lean quality plans with your supplier to lower QA costs.

Streamlining Your Metal Stamping Budget: Practical Tips

- Optimize Part Design for Manufacturability

- Eliminate non‑essential features that require additional die stations or secondary operations.

- Consolidate multiple parts into a single stamping when feasible.

- Select the Right Process for Your Volume

- Low to mid volumes (< 50k/year): Manual or single‑station automated stamping.

- High volumes (> 200k/year): Progressive or transfer dies on high‑speed presses.

- Leverage Supplier Expertise Early

- Engage your stamping supplier during the design phase. Their OEM service engineers can recommend material grades, blank sizes, and die strategies that minimize costs.

- Negotiate Scrap Allowance & Bulk Material Pricing

- As a volume customer, lock in raw material rates with your sheet metal supplier. Lower material costs directly reduce stamping quotes.

- Work with suppliers who can remelt or repurchase your scrap to further offset expenses.

- Consider Life‑Cycle Costs, Not Just First‑Article Price

- A higher initial tooling investment in a progressive die may pay for itself over hundreds of thousands of parts.

- Factor in maintenance intervals, die rebuilds, and expected part lifespan when comparing quotes.

Partner with Topmetalstamping: Your Trusted OEM Service Provider and Supplier

At Topmetalstamping, we deliver comprehensive one‑stop OEM service—from DFM consulting and tool design to high‑precision stamping and final assembly. Our in‑house tool shop, advanced press fleet (60 – 1,200 tons), and turnkey secondary operations mean you deal with a single, accountable supplier rather than a tangle of subcontractors.

Let’s work together to lower your metal stamping costs, improve part quality, and accelerate your time to market. Contact Topmetalstamping today for a detailed cost analysis and see how our expertise can transform your next project into a benchmark of efficiency and reliability.