Hello, culinary innovators and kitchenware buyers! Are you seeking a reliable partner to produce high‑precision, food‑safe watermelon slicer cube cutter forks that delight customers and stand up to daily use? At Topmetalstamping, we provide comprehensive OEM service and advanced manufacturing capabilities—combining precision engineering with rigorous quality assurance. In this deep‑dive, we’ll walk you through every step: from material selection and prototyping to high‑precision stamping, surface finishing, custom branding, and final inspection. By the end, you’ll see why leading chefs and retail brands trust Topmetalstamping for their fruit‑slicing solutions.

1. Understanding the Market Need

Why Watermelon Cube Cutter Forks?

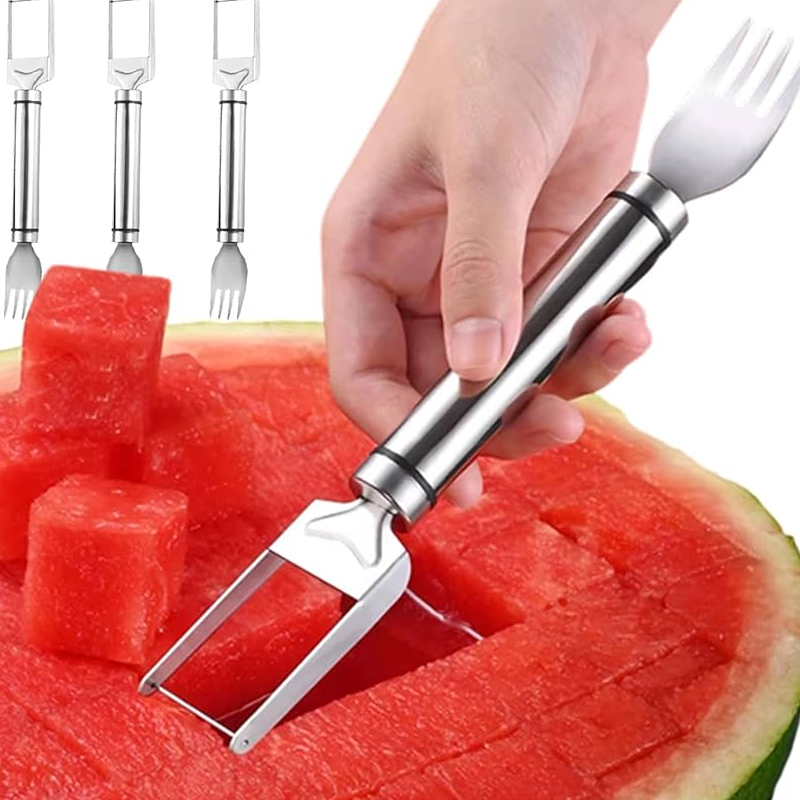

Watermelon is a summer staple, but cutting neat, bite‑sized cubes—and serving them elegantly—can be a challenge in busy kitchens. Our cube cutter forks streamline this process by:

- Slicing and Serving in One Step: Each fork integrates sharp tines aligned to standard cube dimensions (e.g., 1″ or 1.25″), minimizing prep time.

- Food‑Safe, Durable Construction: Stainless steel ensures corrosion resistance and longevity, critical for high‑use commercial and retail environments.

- Ergonomic Design: Handles and fork geometry optimized for comfort and leverage, reducing wrist strain.

Topmetalstamping collaborates closely with chefs, caterers, and consumer goods brands to refine these requirements into concrete design specifications—ensuring the final product not only looks great on retail shelves but also performs flawlessly in everyday use.

2. Material Selection: Premium Stainless Steel Alloys

Choosing the Right Grade

For optimum hygiene, strength, and corrosion resistance, we select from food‑grade stainless steels such as:

- 304 (18/8) Stainless Steel: Excellent corrosion resistance, common in kitchen tools.

- 316 Stainless Steel: Superior resistance to salts and acids—ideal for commercial or coastal applications.

Food‑Contact Safety & Certifications

All our alloys comply with FDA 21 CFR 174/175 guidelines and are free of toxic elements such as lead or cadmium. We maintain full traceability of material batches, providing Certificates of Analysis (CoA) on request.

3. Design & Rapid Prototyping: From Concept to Test Sample

CAD Modeling & Ergonomic Studies

Using advanced CAD software, our engineers translate your requirements—cube size, fork length, handle style—into a 3D model. Biomechanical analysis ensures:

- Optimal Tine Spacing: Precisely aligned for consistent cube dimensions.

- Comfortable Grip Profile: Contoured handles that accommodate varied hand sizes.

Prototype Iterations

- 3D‑Printed Master Models: In durable resin for quick ergonomic testing and functional reviews—ready in 3–5 days.

- CNC‑Machined Aluminum Molds: Small‐batch samples in actual stainless steel, allowing you to validate sharpness, balance, and cube uniformity before full production tooling.

These prototypes let you fine‑tune details—handle length, fork angle, cube depth—ensuring the final product meets both aesthetic and performance benchmarks.

4. High‐Precision Manufacturing: Progressive Stamping & Forming

Progressive Die Stamping

Our state‑of‑the‑art stamping facility uses multi‐station progressive dies to form fork tines, cut fork bodies, and add handle details in a single automated sequence:

- Blanking Station: Cuts the outline of the fork from stainless steel coil.

- Piercing & Shaping Stations: Create tines and handle contours with micron‐level accuracy.

- Bending & Eject Stations: Form ergonomic handle profiles and release finished parts.

This high precision approach yields consistent parts with tight dimensional tolerances (±0.05 mm), ideal for large‐volume production of hundreds of thousands of forks per month.

Secondary Forming

For handle features such as embossing or textured grips, we employ:

- CNC Forging: Enhances material grain structure for added strength.

- Hydroforming: Produces smooth, seamless curves without weld seams.

5. Advanced Surface Coating & Finishing

Polishing & Passivation

After forming, each fork undergoes:

- Mechanical Polishing: Multi‑stage tumbling and buffing to remove burrs and achieve a mirror or satin finish.

- Chemical Passivation: Nitric acid treatment removes free iron and enhances the steel’s natural chromium oxide layer—boosting corrosion resistance.

Optional Coatings for Durability & Aesthetics

- PVD Coatings (Titanium Nitride, Chromium Nitride): Hard, wear‑resistant films available in gold, gunmetal, or black finishes.

- Electro‑Polishing: Further refines surface finish, making cleaning and sanitizing even easier.

- Powder Coating on Handles: For forks with polymer or wooden handles, we offer FDA‑safe powder coatings in custom colors and textures.

Topmetalstamping ensures all coatings comply with food‑contact safety regulations (FDA, EU 10/2011).

6. Customization & OEM Services

Branding & Logo Integration

- Laser Engraving: Permanent, high‑contrast logos or branding on handles.

- Pad Printing: Multi‑color prints for decorative patterns or care instructions.

Packaging Solutions

- Retail Blister Packs: Clear packaging with custom printed backers.

- Gift Sets & Kits: Coordinated die‑cut trays, branded boxes, and user manuals.

- Bulk Bulk OEM Service: Bulk polybags and corrugated cartons for foodservice or promotional use.

Our full one‑stop OEM service handles design, tooling, manufacturing, finishing, packaging, and worldwide logistics—so you can focus on marketing and distribution.

7. Quality Assurance: Rigorous Inspection & Testing

Dimensional & Visual Checks

- CMM & Optical Scanners: Verify tine dimensions, spacing, and handle geometry on 100% of critical parts.

- Surface Roughness Gauges: Ensure finishes meet Ra 0.2 µm or specific customer requirements.

Functional & Durability Tests

- Cube Cutting Trials: Automated test rigs simulate thousands of slicing motions in watermelon-fed rigs, validating tine sharpness retention and fork integrity.

- Corrosion Resistance: Salt‑spray chambers and repeated wash cycles confirm no surface pitting or coating degradation.

- Ergonomic Endurance: Handle grip tests under load cycles to verify no deformation or cracking.

All products are manufactured in our ISO 9001:2015 and IATF 16949 certified facility, guaranteeing consistent quality and full traceability.

8. Delivery & After‑Sales Support

Flexible MOQ & Lead Times

- Sample Runs: Prototype batches as low as 100 units, with sample delivery in 2–3 weeks.

- Mass Production: Volume capacity of 500,000+ forks per month, with lead times of 6–8 weeks after design approval.

Global Logistics

- Shipping Options: FOB Xiamen, CIF, or DDP based on your preference.

- Custom Documentation: Full compliance packs—CoA, MSDS, FDA letters, and export licenses.

Technical & Warranty Support

Our dedicated account managers and technical team provide:

- Installation Guides & Usage Videos for end users.

- Warranty & Replacement Policies ensuring customer satisfaction.

Conclusion:

By combining state‑of‑the‑art precision stamping, advanced surface coatings, and robust OEM services, Topmetalstamping delivers watermelon slicer cube cutter forks that blend functionality with aesthetics. From initial prototyping to high‑volume production, our manufacturing expertise, rigorous quality assurance, and custom branding solutions make us the ideal partner for kitchenware brands worldwide.

Ready to bring your custom slicer forks to market? Contact Topmetalstamping today for a free design consultation, prototype quote, or factory tour—and let us turn your vision into high‑quality, premium stainless steel slicer forks that customers will love.