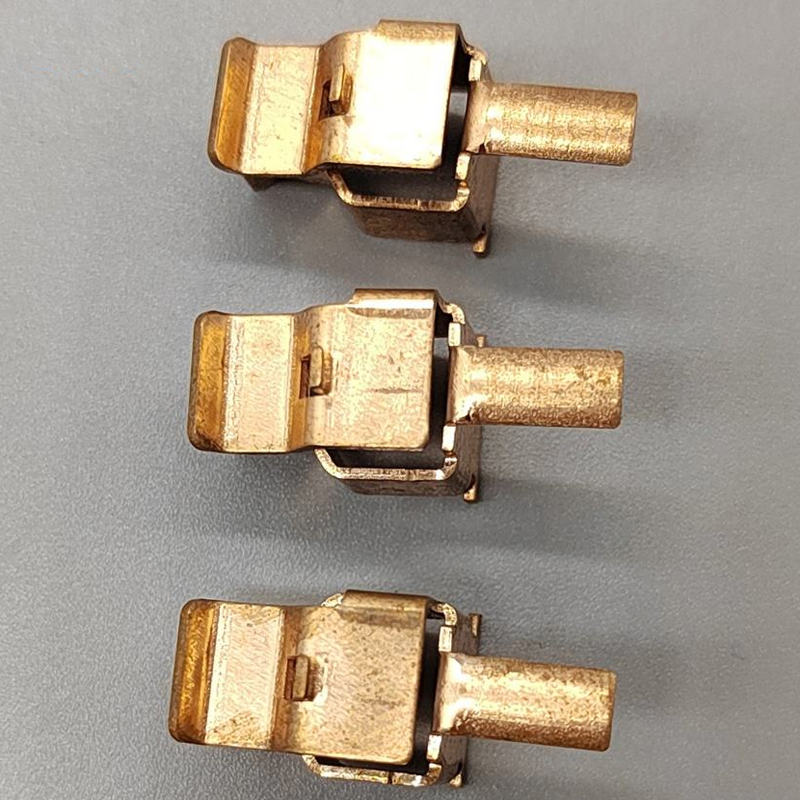

Overview:

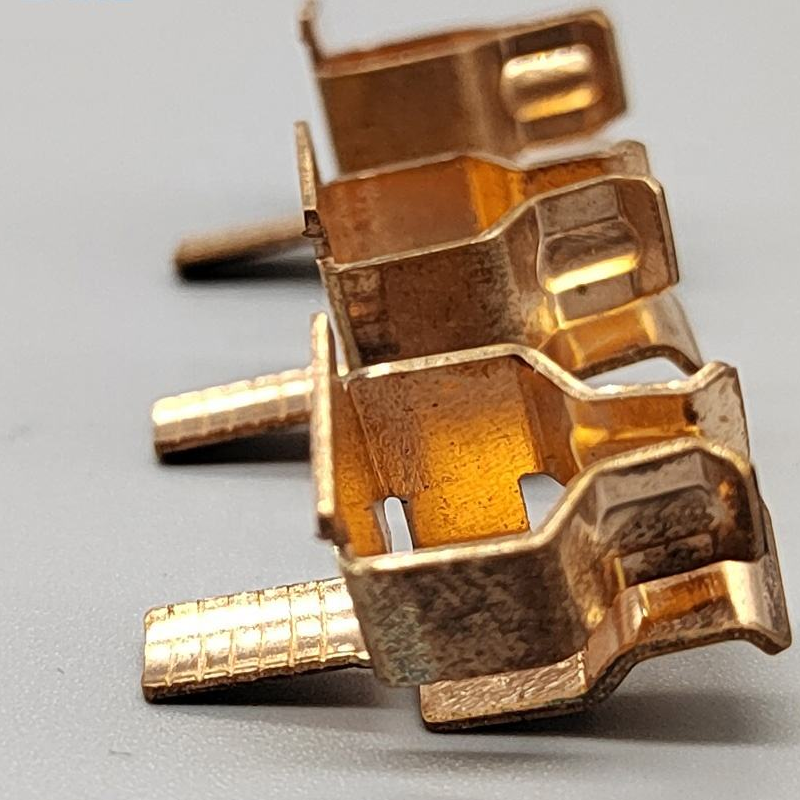

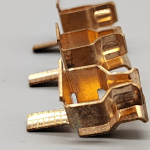

Our Customized Progressive Stamping High Conductive Brass Contacts are expertly engineered for superior electrical performance and reliability in socket plug applications. Manufactured from high-quality brass and other copper alloys, these contacts undergo advanced progressive stamping and precision die-pressing technology to ensure consistent, repeatable performance. The contacts are designed to provide exceptional conductivity and are coated with high-performance electroplated finishes, such as nickel, tin, silver, or gold, to meet specific application needs. Ideal for high-demand electrical connections, these brass contacts are perfect for use in both consumer and industrial socket plugs, ensuring long-term durability and optimal conductivity.

Product Characteristics:

| Attribute | Details |

|---|---|

| Material | Brass, Copper-5191, C-1100 Copper Alloy |

| Standard | ISO 9001, IATF 16949 |

| Color | Customizable |

| Size | Customizable, based on specifications |

| Usage | Electrical applications, Socket Plug |

| Sample | Available upon request |

| MOQ | Small orders accepted |

| Surface Treatment | Nickel Plating, Tin Plating, Silver Plating, Gold Plating |

| Certification | RoHS, UL Compliant, ISO 9001 |

| Service | OEM, one-stop solution (from tooling to mass production) |

Key Benefits:

- Superior Electrical Conductivity

Manufactured from high-conductivity brass alloys (C-1100, Copper-5191), ensuring high-performance electrical connections with low resistance. - Enhanced Corrosion Resistance

The progressive stamping process, combined with electroplating (Nickel, Tin, Silver, or Gold), provides robust protection against oxidation, ensuring longevity and stable performance. - High Precision & Repeatable Performance

Precision progressive stamping ensures tight tolerances and consistent quality across large production volumes. The contact shape and dimensions are carefully controlled, ensuring perfect fit and reliable electrical connections. - Cost-Effective Scalability

The use of advanced tooling and mass production capabilities allows for highly efficient manufacturing at competitive prices, making it ideal for high-volume applications without compromising quality.

Surface Treatment Options:

- Nickel Plating

Offers excellent wear resistance and corrosion protection, making it ideal for long-lasting performance in demanding environments. - Tin Plating

Provides superior solderability and oxidation resistance, ensuring a stable connection and reliability for electrical devices. - Silver Plating

Enhances electrical conductivity and thermal performance, making it perfect for high-performance electronic components where superior signal transmission is required. - Gold Plating

Offers exceptional conductivity, oxidation resistance, and long-term reliability, ideal for high-end electrical applications that demand optimal signal quality.

Factory Capabilities:

Our advanced manufacturing facility is equipped with cutting-edge technology to ensure precision and quality in every component:

- Precision Equipment: 25 high-performance punch presses with capacities from 25 to 300 tons, alongside precision wire EDM machines and advanced grinding systems.

- Plating Solutions: A full range of plating options, including nickel, tin, silver, and gold electroplating, ensuring consistent, high-quality finishes.

- Automated Production: Automated production lines optimized for high-volume, high-precision manufacturing, ensuring efficiency and consistency across all orders.

- Quality Control: Rigorous in-house quality inspections using state-of-the-art inspection equipment such as CMMs (Coordinate Measuring Machines), tensile testers, and 3D projectors to guarantee the precision and performance of each component.

Quality Assurance:

As a ISO 9001 and IATF 16949 certified facility, we maintain rigorous quality control standards throughout our production process. We implement comprehensive testing protocols, including:

- First-Article Inspection (FAI) to validate initial production quality.

- In-process inspections to ensure consistency during mass production.

- Final product assessments for surface quality, plating thickness, and electrical performance.

Additionally, our quality control system includes electrical conductivity testing, hardness verification, and dimensional accuracy checks to ensure that each contact meets the highest standards for reliability and performance.

Why Choose Us?

- Industry-Leading Experience: Over 20 years of expertise in manufacturing high-performance metal stamping components for the electrical industry.

- Custom Solutions: Tailored to your specific needs, from material selection to plating options and custom sizing.

- Advanced Production Capacity: High-volume production capability while maintaining exceptional quality and precision.

- Comprehensive Service: End-to-end support, from prototyping to final delivery, with a focus on customer satisfaction and on-time delivery.

- Certified Quality: We are committed to exceeding industry standards, offering products that are certified RoHS, UL compliant, and ISO 9001 certified.

Reviews

There are no reviews yet.