Overview:

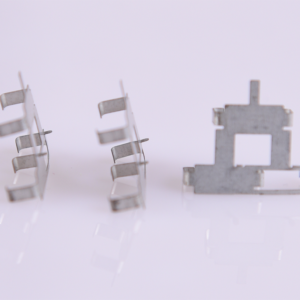

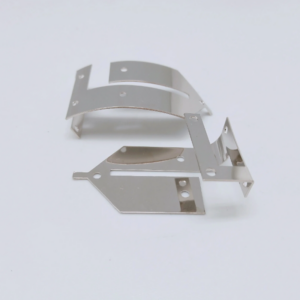

The OEM Progressive Metal Stamping Brass Electric Angle Bracket is a high-precision, cost-effective solution designed to provide durable support and stability in electrical systems and various industrial applications. Manufactured using premium brass and crafted through advanced progressive stamping processes, these angle brackets offer exceptional strength, corrosion resistance, and ease of installation. With our extensive manufacturing expertise and commitment to quality, we deliver reliable components that meet the specific needs of your project, ensuring optimal performance at competitive factory prices.

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Brass |

| Dimension | Custom dimensions as per drawings or samples |

| Sample | Available upon request |

| Certification | ISO 9001:2015, IATF 16949:2016, RoHS |

| OEM | Yes |

| MOQ | Based on customer requirements |

| Tolerance | +/- 0.01mm or customized |

| Inspection | 100% factory inspection in-house |

| Process | Progressive Stamping, Laser Cutting, Bending |

| After-Sale Service | Yes, ongoing support and service |

Key Features of Our Brass Electric Angle Bracket:

- Premium Brass Material:

Made from high-quality brass, a material known for its strength, durability, and excellent corrosion resistance. This makes the angle bracket ideal for use in electrical and industrial applications where reliability is critical. - Progressive Stamping Technology:

Manufactured using progressive stamping techniques that ensure high precision, consistent quality, and repeatability. This allows us to create complex designs and reduce waste during production. - Durable and Long-Lasting:

Brass provides excellent resistance to corrosion, rust, and wear, ensuring that the brackets maintain their strength and appearance over time, even in harsh environments. - Customizable Dimensions and Designs:

We offer custom dimensions based on your design requirements, ensuring that the brackets fit perfectly within your application. Whether you need small-scale runs or large volumes, we can accommodate your needs. - Competitive Pricing:

With our factory direct pricing, we provide high-quality brass angle brackets at a competitive price, helping you meet budget requirements while maintaining performance and durability.

Surface Treatment Options:

- Anodizing:

A surface treatment that creates a protective oxide layer, significantly enhancing the corrosion resistance and wear characteristics of the metal. This is ideal for applications exposed to harsh weather or high humidity. - Powder Coating:

Offers a durable finish that is resistant to chipping, scratching, and fading, providing long-lasting protection to the metal. The finish is customizable to a wide range of colors, ensuring your product matches your brand. - Electroplating:

A thin layer of metal is applied to the surface to improve corrosion resistance, increase electrical conductivity, and provide an aesthetic finish. It is particularly useful for components that require enhanced conductivity or a decorative appearance. - Polishing:

A process that smoothens the metal surface to achieve a high-gloss finish, improving aesthetics and reducing friction, which is especially useful for precision components.

Quality Assurance:

Our Quality Assurance (QA) process ensures that each brass electric angle bracket meets the highest industry standards. We utilize Coordinate Measuring Machines (CMM) for precise dimensional verification, ensuring that components meet customer specifications. To guarantee material integrity, each batch of brass undergoes rigorous testing, including hardness tests and material composition analysis, to ensure strength, durability, and resistance to corrosion. Additionally, every batch of components undergoes 100% in-house inspection to confirm they are free from defects, meet dimensional requirements, and perform as expected. We operate under ISO 9001:2015 and IATF 16949:2016 certifications, ensuring compliance with international quality standards, and adhere to RoHS guidelines to meet environmental safety regulations.

Factory Show:

Our manufacturing facility is equipped with state-of-the-art equipment, including progressive stamping presses, CNC machining centers, and advanced laser cutting and bending systems to ensure precise, high-quality production. With an extensive range of inspection tools such as coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers, we ensure that every component meets the highest standards of quality and reliability.

We are fully certified to ISO 9001:2015 and IATF 16949:2016 standards, and our processes are optimized for maximum efficiency, quality, and consistency. Our commitment to excellence is reflected in our strict quality control protocols, automated systems, and continuous improvement efforts to ensure that we deliver the best possible products at the most competitive prices.

Reviews

There are no reviews yet.