Description:

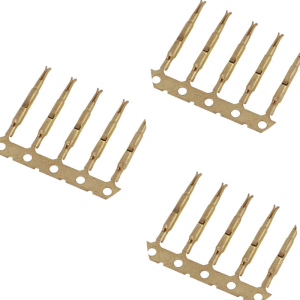

OEM Metal Stamping Stainless Steel Block Wiring Terminals are precision-engineered components designed to provide secure and reliable electrical connections in PCB assemblies, power distribution systems, and baseboard applications. Manufactured from high-quality stainless steel and other conductive metals, these wiring terminals deliver superior mechanical strength, excellent conductivity, and long-lasting durability. Utilizing advanced progressive die stamping and precision forming processes, each terminal is crafted with tight tolerances to ensure compatibility with PCB layouts and power modules.

Engineered to meet the demanding requirements of the electronics, automotive, and industrial power sectors, these stainless steel wiring terminals are available in custom dimensions, plating finishes, and configurations to suit diverse application needs. Fully compliant with ISO 9001 and IATF 16949 standards, they are the ideal choice for manufacturers seeking high-performance, cost-effective, and scalable connection solutions.

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Process | Precision Metal Stamping / Progressive Die Stamping |

| Material | Stainless Steel 301/304, Brass, Copper Alloys, Aluminum 5052 |

| Tolerance | ±0.01mm |

| OEM Service | Warmly Welcome |

| QC Control | 100% Inspection |

| Standard | ISO9001, IATF16949 |

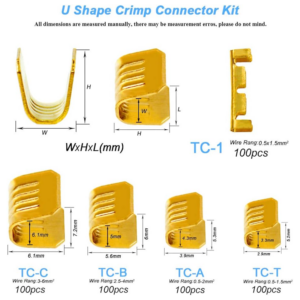

| Size | Customized according to PCB and application requirements |

| Sample | Available upon request |

Advantages of Our Terminals:

- High-strength stainless steel with excellent conductivity

- Precision metal stamping for consistent quality and performance

- Enhanced resistance to corrosion, wear, and mechanical stress

- Customizable shapes, sizes, and plating options for diverse applications

Alternative Surface Treatment Options:

- Tin Plating: Ensures excellent solderability and corrosion resistance, widely used in PCB and electronic connections.

- Nickel Plating: Enhances wear resistance and provides stable conductivity under demanding conditions.

- Silver Plating: Delivers superior electrical conductivity, ideal for high-performance power applications.

- Gold Plating: Provides exceptional corrosion resistance and premium conductivity for critical electronic components.

- Anodizing (for aluminum parts): Increases corrosion resistance and surface durability.

Why Partner with Us?

- Direct Factory Pricing: Cost-efficient solutions with competitive pricing from a certified manufacturing facility.

- Strict Quality Assurance: First article, in-process, and final inspections ensure compliance with ISO 9001 and IATF 16949 standards.

- Comprehensive Support: From design optimization and prototyping to mass production and after-sales service, we provide end-to-end solutions.

- On-Time Delivery: Streamlined production management and efficient logistics guarantee reliable delivery schedules.

Our Factory:

Our state-of-the-art manufacturing facility is equipped with 25 punch presses ranging from 25 to 300 tons, high-precision CNC machining, progressive die stamping, wire EDM, and automated polishing systems. To support high-performance requirements, we provide advanced plating services including tin, nickel, silver, gold, chrome, and anodizing, ensuring terminals achieve the desired conductivity, durability, and appearance.

Quality is strictly controlled with advanced inspection systems such as CMM machines, optical measurement systems, hardness testers, and conductivity meters, monitored by our professional QC team. With automated lines, professional engineering teams, and certifications including ISO 9001 and IATF 16949, we ensure every wiring terminal meets the highest industry benchmarks.

Reviews

There are no reviews yet.