Description

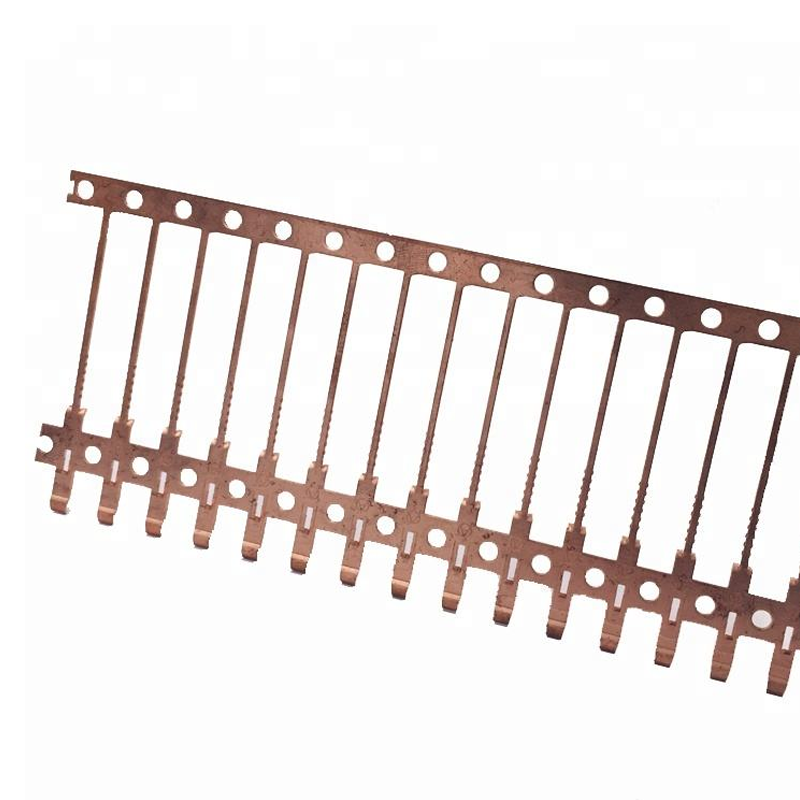

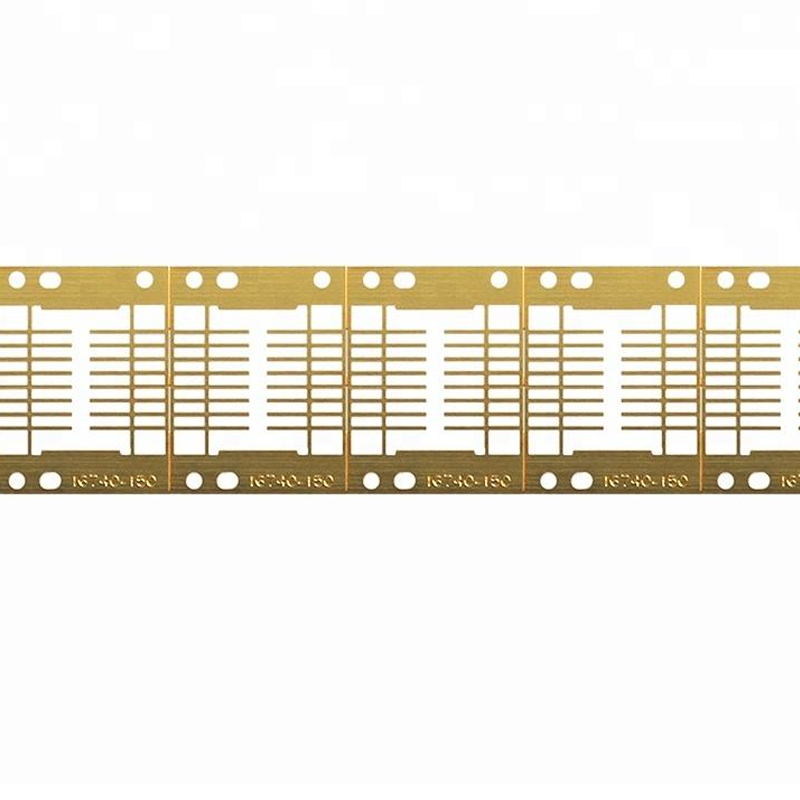

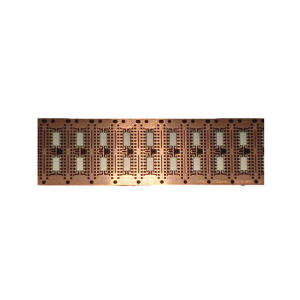

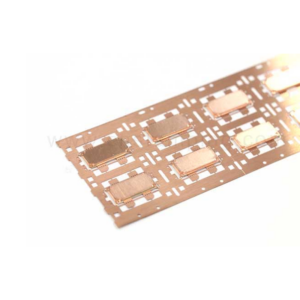

Our OEM progressive die-stamped lead frames are engineered for high-precision integrated circuit (IC) packaging and semiconductor assembly. Manufactured from high-conductivity copper and copper-alloys (C194, C5191, C1100, phosphor bronze options) using progressive die stamping and secondary forming, these lead frames deliver exacting geometry, repeatable flatness, and stable metallurgical properties required for wire bonding, soldering, and automated pick-and-place. We offer controlled electroless nickel / gold (ENIG) and hard-gold plating options to ensure superior corrosion resistance, solderability, and reliable electrical contact. Full turnkey services include tool design, rapid prototyping, pilot runs, high-volume production, and post-plating precision trimming—tailored for memory, logic, power ICs, and specialty semiconductor packages.

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Product | Progressive Die-Stamped Lead Frames (Gold-Plated) |

| Base Materials | Copper C1100, Copper Alloy C194, C5191, Phosphor Bronze |

| Plating System | ENi / Au (electroless Ni + hard gold), Flash Au, Sn, Ag options |

| Standard Thickness | 0.10 mm – 0.50 mm (other gauges available) |

| Dimensional Tolerance | ±0.01 mm (high-precision tolerances on request) |

| Minimum Feature Pitch | down to 0.25 mm (depends on geometry) |

| Contact Resistance | Typical < 20 mΩ (application dependent) |

| Sample Lead Time | 5–10 business days |

| Production Lead Time | 2–6 weeks (volume & tooling dependent) |

| MOQ | Small pilot runs accepted; scalable to mass production |

| Certifications | ISO 9001, IATF 16949, RoHS, REACH |

| Services | Tool & die design, progressive tooling, secondary forming, plating, laser trim, kitting |

Key Advantages

- High Geometric Precision: Progressive die tooling delivers consistent pitch, coplanarity, and flatness for automated assembly and reliable solder/wire-bond processes.

- Superior Surface Reliability: ENi + Au or hard-gold finishes provide low contact resistance, excellent corrosion resistance, and proven wire-bond/solder compatibility.

- Scalable Production: In-house progressive presses and automated plating lines support rapid prototyping through high-volume runs with stable cycle-to-cycle repeatability.

- Custom Engineering: Tooling, material selection, plating thickness, and secondary forming are optimized to meet electrical, thermal, and mechanical requirements of each IC package.

Typical Process Flow

- Design & DFM: CAD design, strip layout, and progressive-stage planning with process simulation to minimize scrap and optimize yield.

- Progressive Die Tooling: Multi-station progressive dies manufactured in-house with hardened tool steels and precision EDM finishing.

- Stamping & Secondary Forming: High-speed progressive stamping presses (precision blanking, bending, flanging) with automated strip handling.

- Stress Relief & Anneal: Controlled annealing to stabilize metallurgy and improve formability where required.

- Surface Preparation & Plating: Degrease → activation → electroless Ni underplate (typ. 1–5 µm) → gold plating (50–500 nm typical) or specified alternative.

- Post-Plating Trim & Inspection: Laser or mechanical trim, coplanarity correction, dicing, and final dimensional/visual inspection.

- Kitting & Cleanroom Packaging: ESD-safe, contamination-controlled packing for shipment or direct line-feed delivery.

Alternative Surface Treatments

- Tin (Sn) Plating: Cost-effective solderable surface for SMT applications.

- Silver (Ag) Plating: Excellent conductivity and contact performance for certain connectors.

- Nickel (Ni) Plate (Hard Ni): Wear-resistant underplate for heavy-duty contacts.

- Selective Plating / Masking: Localized plating to expose bond pads while protecting other areas.

Quality Assurance & Testing

- Material Verification: XRF / OES spectrometry to confirm alloy composition.

- Plating Thickness & Coverage: XRF and coulometric testing to verify Ni/Au thickness and uniformity.

- Dimensional Control: CMM, optical comparators, and high-speed vision systems for pitch, coplanarity, and profile checks.

- Electrical & Mechanical Tests: Contact resistance measurement, solderability tests, wire-bond pull/shear tests, and thermal cycling.

- Surface & Cleanliness: SEM/EDS for microstructure if required; ionic cleanliness and particulate control for sensitive packages.

- Traceability: Lot-based serial coding, FAI reports, and full process documentation per customer requirements.

Why Partner With Us?

- Engineering-Driven Tooling: In-house progressive-die design and rapid tool iteration reduce time-to-market and tooling cost.

- Stringent Quality Systems: ISO 9001 and IATF 16949 governance with 100% inspection protocols for critical features.

- Flexible Volume Support: From engineering prototypes and small pilot lots to millions of stamped lead frames per month.

- Turnkey Supply Chain: Integrated stamping, heat treatment, plating, and packaging reduce logistics complexity and improve supply reliability.

Our Factory Capabilities

We operate an advanced metal-fabrication campus with 30+ precision progressive presses (25–300 tons), in-house die-making with EDM and surface grinding, controlled annealing furnaces, automated electroplating lines (ENi/Au, Sn, Ag), laser trimming stations, and comprehensive metrology suites (CMM, XRF, SEM). Clean handling, ESD-safe processes, and automated strip-to-part flow ensure consistent, high-yield production for demanding IC packaging customers.

-300x300.png)

Reviews

There are no reviews yet.