Overview

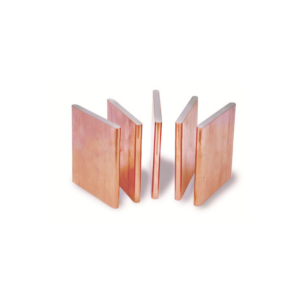

Our Custom High-Precision Tinned Nickel Aluminum Stamping Electric Busbar Sheets are engineered for high-efficiency power distribution in electric vehicles (EVs), energy storage systems, and industrial power modules. Manufactured from lightweight, high-conductivity aluminum alloys with optional tin or nickel plating, these busbars combine electrical performance with superior corrosion resistance and cost-effectiveness. Through advanced CNC machining, progressive die stamping, and precision laser cutting, we achieve tight dimensional tolerances and consistent quality. As a trusted OEM partner, we offer complete end-to-end solutions—from rapid prototyping and material optimization to high-volume production and custom finishing—ensuring reliable integration into your power systems.

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM / Custom Branding |

| Material | High-conductivity aluminum alloy (1050, 1060, 6061, or custom grade) |

| Surface Finish | Tin plating / Nickel plating / Anodized / Bare aluminum |

| Thickness Range | 0.8 mm – 6.0 mm (customized) |

| Dimensions | Custom shapes and layouts per customer drawings |

| Manufacturing Process | Precision stamping / CNC machining / Laser cutting / Bending / Welding |

| Tolerance | ±0.05 mm (standard); tighter tolerance available upon request |

| Color | Silver, metallic gray, or customized finish |

| MOQ | Small prototype batches accepted |

| Sample Lead Time | 5–10 business days |

| Production Lead Time | 15–30 business days (depending on tooling and order volume) |

| Certifications | ISO 9001, IATF 16949, RoHS, REACH |

| Packaging | Anti-static or vacuum-sealed export packaging |

| Applications | EV battery modules, inverters, charging systems, energy storage units, and power electronics |

Surface Finishing Options

- Nickel Plating: Provides excellent corrosion resistance, enhanced wear protection, and stable electrical conductivity in harsh environments.

- Tin Plating: Ensures strong solderability, oxidation resistance, and uniform current flow—ideal for mass-assembled electrical modules.

- Anodizing: Offers protective oxide coating for improved surface hardness and extended service life.

- Custom Coatings: Available per client specifications to meet thermal, mechanical, or electrical performance targets.

Key Advantages

- Lightweight & Efficient: Aluminum structure offers high current capacity with reduced system weight for EV and power electronics applications.

- High Precision Fabrication: Achieved through CNC milling, stamping, and laser cutting with ±0.05 mm tolerance control.

- Excellent Corrosion Resistance: Tin or nickel plating provides superior oxidation protection and reliable performance under high humidity or temperature cycles.

- Custom Engineering Support: OEM services for geometry, busbar layout, insulation integration, and multi-layer laminations.

- Enhanced Cost-Performance Ratio: Optimized for lightweight construction and long service life while maintaining excellent conductivity and mechanical stability.

Quality Assurance

Every busbar sheet undergoes a comprehensive, ISO 9001 and IATF 16949-compliant quality assurance process:

- Raw Material Inspection: Conductivity and composition verification using X-ray fluorescence (XRF) and spectrographic analysis.

- Dimensional Verification: Measured via coordinate measuring machines (CMM) and 3D optical scanners to ensure micron-level precision.

- Surface & Plating Validation: Coating thickness tested using XRF and adhesion strength confirmed via peel and salt-spray tests.

- Mechanical Testing: Tensile, hardness, and bend tests validate structural integrity under load conditions.

- Electrical Conductivity Testing: Four-point probe resistance testing ensures high current transfer efficiency and minimal power loss.

- Thermal Cycling Simulation: Repeated heat-aging tests to confirm long-term stability in EV operating environments.

All inspection results are digitally logged for traceability, ensuring full compliance with RoHS and REACH standards.

Factory Capabilities

Our advanced facility integrates multi-axis CNC machining, high-speed precision stamping (25–300 tons), and automated laser cutting to produce complex busbar geometries with exceptional consistency. Equipped with in-house plating lines for nickel, tin, and anodized finishes, we control every step of production—from tooling to finishing. Our quality assurance lab employs 3D measurement systems, XRF spectrometers, hardness testers, and conductivity analyzers operated by certified QC specialists.

With ISO 9001 and IATF 16949 certifications, we guarantee automotive-grade quality, fast prototyping, scalable production, and on-time global delivery.

Reviews

There are no reviews yet.