In today’s advanced manufacturing world, achieving high-quality joints between materials is crucial for the success of many industries. Traditional welding techniques, while effective, may not always offer the best results in certain applications. Enter friction welding, a solid-state joining process that allows manufacturers to produce strong, reliable bonds without the need to melt the materials involved. At Plantmetal, we are committed to providing custom services with high precision, utilizing state-of-the-art technologies like friction welding to meet your manufacturing needs.

In this detailed guide, we will explore what friction welding is, how it works, the various types of friction welding processes, and its advantages and applications. By understanding this process, manufacturers and engineers can make informed decisions when selecting the most suitable method for their projects.

What is Friction Welding?

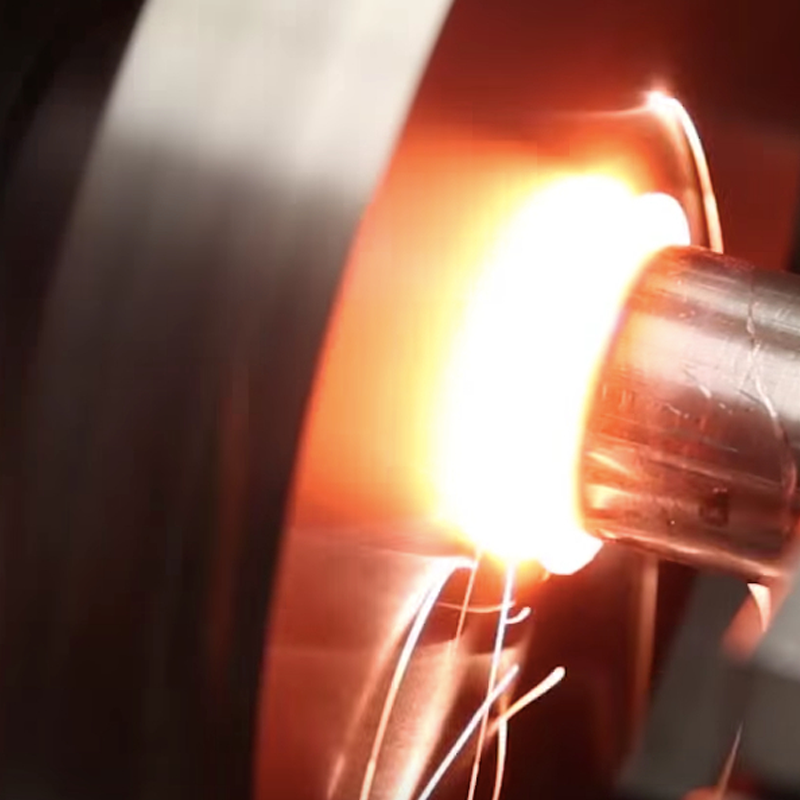

Friction welding (FW) is a solid-state joining technique where heat generated by mechanical friction between two components under pressure leads to a metallurgical bond, all without melting the base materials. The primary mechanism involves creating frictional heat through rotational or linear motion, softening the materials at the interface. When the motion stops and pressure is maintained, the softened materials fuse together to form a strong, durable joint.

This technique is used widely in industries requiring high-performance, long-lasting welds without the drawbacks of traditional fusion welding methods, such as porosity, cracking, or material segregation.

The History of Friction Welding

The concept of using friction-generated heat to join materials dates back to the early 20th century. The initial experiments in the Soviet Union paved the way for the development of rotary friction welding (RFW). During the 1950s and 60s, advancements in machine tool design and hydraulic systems facilitated the automation of the process, allowing for precise, high-quality welds across a range of materials.

Friction welding technologies have continued to evolve with the introduction of new techniques such as linear friction welding (LFW) and friction stir welding (FSW), the latter of which revolutionized aluminum joining applications. With modern automation and robotics, friction welding has become a highly precise and cost-effective option for a wide variety of industries, including aerospace, automotive, energy, and medical manufacturing.

How Does Friction Welding Work?

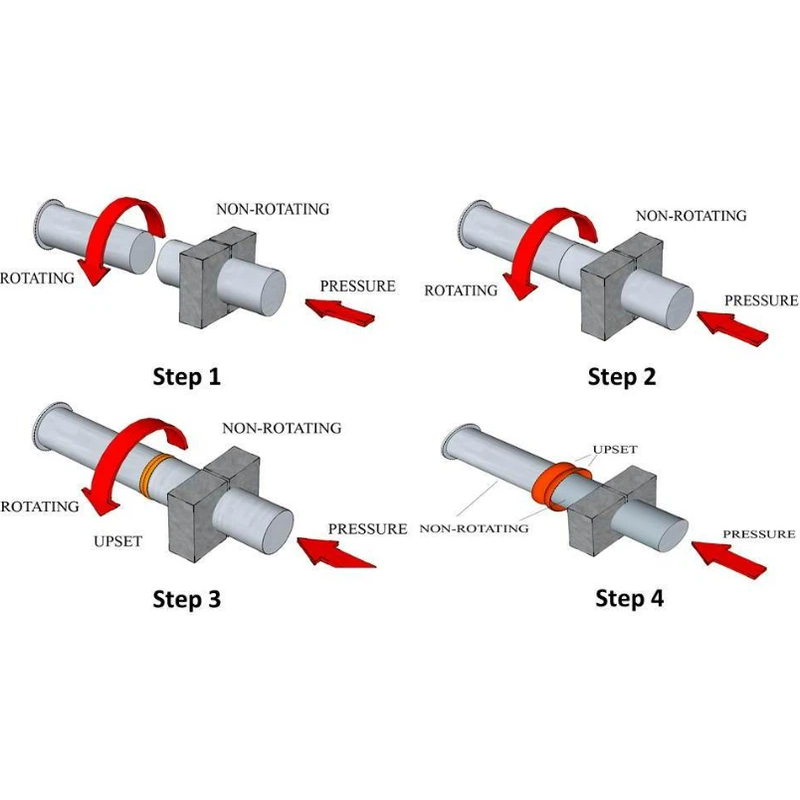

The process of friction welding can be broken down into three primary stages:

- Friction Stage: During this stage, one component is either rotated or subjected to linear motion relative to the other. The friction between the surfaces generates heat, softening the material at the contact interface. This heating is carefully controlled to avoid melting, ensuring the integrity of the base materials.

- Forging (Upsetting) Stage: Once the required temperature is reached, the relative motion stops, and additional axial pressure is applied. This pressure helps to expel surface contaminants and oxides, ensuring a clean bond between the materials. The components are pressed together to achieve a solid, metallurgical connection.

- Cooling and Solidification Stage: During the final stage, the joint cools and solidifies under continued pressure, resulting in a durable, strong bond that has minimal deformation.

Types of Friction Welding

Friction welding comes in several variations, each suitable for different applications:

- Rotary Friction Welding (RFW): The most widely used form of friction welding, RFW involves one component rotating at high speeds while the other remains stationary. The resulting friction generates heat, which allows for the materials to bond when the rotation stops. This method is commonly used for joining cylindrical components like shafts and pipes.

Applications: Automotive parts, aerospace components, and piping systems.

- Linear Friction Welding (LFW): Unlike RFW, LFW involves linear reciprocating motion between the two components. This method is ideal for joining parts with complex geometries or non-circular shapes, such as aerospace turbine components.

Applications: Jet engine parts, aerospace bladed disks, and automotive structural components.

- Friction Stir Welding (FSW): FSW is a derivative of friction welding that uses a non-consumable rotating tool to stir the materials together, forming a solid-phase joint. This method is particularly effective for welding aluminum and other soft metals, creating continuous, defect-free welds.

Applications: Aluminum sheet metal joining, shipbuilding, and rail vehicle fabrication.

- Low-Force Friction Welding (LFFW): This method reduces the axial force required for welding by using preheating techniques like induction or resistance heating. This makes it suitable for joining lightweight or thin-walled materials without excessive deformation.

Applications: Precision electronics and lightweight automotive parts.

- Friction Stud Welding and Friction Plug Welding: These methods involve the use of rotating studs or plugs to join materials in a localized area, often for repairs or connections.

Applications: Ship hull repairs, aerospace maintenance, and pressure vessel repair.

Materials That Can Be Welded with Friction Welding

One of the key advantages of friction welding is its ability to join a wide variety of materials, including metals that are difficult or impossible to weld using conventional fusion methods. These include:

- Steel and Stainless Steel: Commonly used in automotive, industrial machinery, and energy sectors.

- Aluminum and Aluminum Alloys: Friction welding overcomes challenges like aluminum’s oxide layer and high thermal conductivity, which make traditional welding methods difficult.

- Copper and Copper Alloys: Known for excellent electrical conductivity, copper can be effectively welded using friction welding.

- Titanium and Nickel Alloys: High-temperature alloys such as titanium and nickel are frequently used in the aerospace and medical industries due to their strength and resistance to corrosion.

- Dissimilar Metal Combinations: Friction welding excels at joining materials with different properties, such as aluminum to steel or copper to aluminum, making it ideal for hybrid structures in industries like automotive and energy.

Advantages of Friction Welding

Friction welding offers several benefits over traditional fusion welding methods:

- High Joint Strength: The process creates a solid, metallurgical bond without the need for filler materials or shielding gas, resulting in stronger, more reliable joints.

- No Heat-Affected Zone (HAZ): The small heat-affected zone minimizes material distortion and preserves the mechanical properties of the base materials.

- Clean Joints: The absence of melting and filler materials ensures clean joints, free from defects like porosity or cracks.

- Efficiency: The short cycle times make friction welding highly suitable for mass production, especially for industries requiring high-volume, repetitive processes.

- Versatility: Friction welding can join dissimilar metals and materials that are difficult to weld using conventional methods.

Limitations of Friction Welding

Despite its many advantages, friction welding does have a few limitations:

- High Initial Equipment Cost: The machines required for friction welding can be expensive, particularly those capable of handling specialized processes like friction stir welding.

- Limited to Certain Geometries: Friction welding works best with certain shapes, particularly round or cylindrical components. Complex geometries may require other methods.

- Preparation and Alignment: The process requires precise alignment of components, and preparation may take longer compared to simpler welding methods.

- Material and Size Restrictions: While friction welding can handle a wide variety of materials, the size and material combinations that can be welded may be limited by the machine’s capacity.

Friction Welding vs. Traditional Welding Methods

When compared to traditional fusion welding techniques like TIG or MIG, friction welding offers several distinct advantages:

- Heat Source: Friction welding uses mechanical friction to generate heat, whereas traditional welding methods use electric arcs or gas flames.

- Material State: Friction welding is a solid-state process, meaning the materials are not melted, which eliminates many of the defects seen in fusion welding.

- Distortion: Friction welding causes minimal material distortion, unlike fusion welding methods that can lead to significant warping.

- Automation: Friction welding is highly automated, making it ideal for high-volume production, whereas traditional welding often requires more manual labor.

Applications of Friction Welding

Friction welding is used in a variety of industries and applications, including:

- Automotive: Drive shafts, engine components, and suspension parts.

- Aerospace: Aircraft structural components, turbine parts, and fuel systems.

- Energy and Power Generation: Heat exchangers, turbine shafts, and drill pipes.

- Railroad and Shipbuilding: Joining long aluminum sheets and high-strength structural components.

- Medical and Electronics: Manufacturing of implants, medical devices, and precision electronic connectors.

Conclusion

At Plantmetal, we specialize in precision manufacturing and assembly, offering comprehensive services including friction welding, CNC machining, stamping, and automated assembly. Our experienced team uses advanced technologies and strict quality control to ensure that every part we produce meets the highest standards of performance and durability. Whether you’re looking for custom sealing solutions, high-precision components, or mass production capabilities, we are here to help you every step of the way.

Contact us today to learn more about our friction welding capabilities and discover how we can help optimize your production process with our custom services. With Plantmetal as your trusted supplier and manufacturing partner, you can be confident in the quality and reliability of every part we create.