Thanks — before we dive in: have you ever wondered which metallizing method will give your parts the best mix of durability, finish, and cost? At Topmetalstamping we get that question every day, and this guide is written from the viewpoint of a production-focused manufacturer so you can choose the right metallization path for your products and supply chain. If you’re evaluating finishes for a new design or prepping parts for mass production, read on — we’ll walk through processes, typical materials, equipment needs, design considerations, and real-world tradeoffs so you can make an informed OEM decision.

What is metallization — a practical definition

In manufacturing terms, metallization is the controlled deposition of a metal layer onto a substrate (metal, plastic, glass, ceramic, composite, or elastomer) to add functionality: conductivity, reflectivity, corrosion resistance, wear protection, or simply premium cosmetics. Unlike paint or surface plating that sits on the surface, metallization—depending on the method—can provide metallurgical bonding, dense coatings, or ultrathin conductive layers suited to electronics, optics, and consumer finishes.

Core metallization methods and when to use each

Manufacturers and suppliers choose processes based on substrate, required coating thickness, part geometry, temperature sensitivity, production volume, and cost. Here are the major methods we use and recommend at Topmetalstamping:

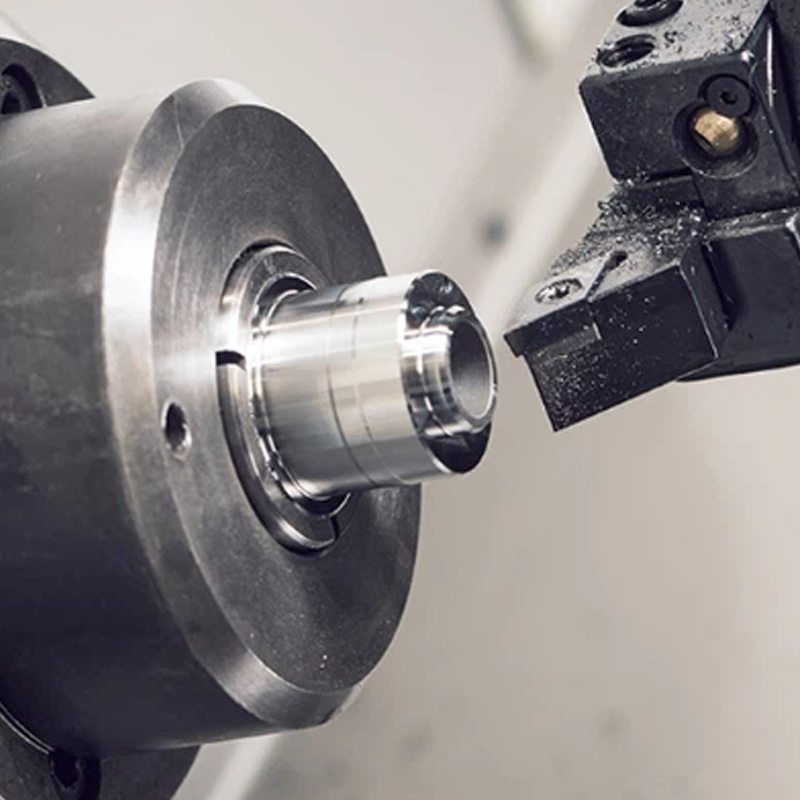

• Thermal spray (flame, arc, HVOF, plasma): melts wire or powder and propels droplets that build up a thick, wear-resistant coating. Best for heavy-duty protection (industrial valves, shafts, pump housings) and repair work. Good for large parts but often requires finish grinding for tight tolerances.

• Vacuum metallization / PVD (Physical Vapor Deposition): produces very thin, uniform coatings with excellent appearance and color stability — ideal for decorative trims, reflectors, and thin conductive films. PVD offers high-precision control at the nanometer–micrometer scale.

• Sputtering: a form of PVD that’s excellent for precision electronics and optical coatings where uniformity and adhesion are critical.

• Electroplating: electrochemically deposits metals such as nickel, copper, chrome, or gold onto conductive parts. It’s a workhorse for corrosion resistance, conductivity, and decorative chrome-like finishes — especially in high-volume runs.

• Electroless (chemical) plating: deposits metal on non-conductive substrates after activation. It’s essential when metallizing plastics (ABS, PC) or composites for EMI shielding or decorative effect.

• Cold spray: a low-temperature, high-velocity process suitable for coating temperature-sensitive parts without thermal distortion.

• Hot-dip metallizing (galvanizing): immersion in molten zinc/aluminum for thick, sacrificial corrosion protection on structural steel.

Which substrates can be metallized?

A major advantage of modern metallization is broad substrate compatibility — when correctly prepared:

• Metals (steel, aluminum, copper, titanium) — plated, sprayed, or PVD.

• Plastics (ABS, PC, PA, PP with activation) — typically electroless + electroplate or vacuum-coated.

• Glass and ceramics — PVD and sputtering for reflectors and decorative surfaces.

• Composites and elastomers — thin films for EMI shielding or aesthetic finishes.

• Textiles, paper, and film — vacuum-coated for packaging and insulation uses.

Surface preparation: the make-or-break step

No finish survives poor prep. Surface cleaning and activation are critical:

• Degreasing and ultrasonic cleaning remove oils and residues.

• Mechanical roughening (sandblasting) increases mechanical bonding for sprays/thermal coats.

• Chemical etching, plasma, or chromatization activates plastics for electroless plating.

• Masking, drying, and controlled humidity prevent defects.

Topmetalstamping enforces documented surface-prep recipes depending on the process and material — it’s one of the most common causes of rework when omitted.

Selection criteria: match performance to process

When advising OEM customers we evaluate:

• Required coating thickness — thin decorative films (PVD/sputter) vs. thick wear layers (thermal spray/hot-dip).

• Thermal sensitivity — plastics and assemblies often rule out high-temp options; electroless plating or cold spray are typical choices.

• Geometry and internal features — deep recesses and internal channels favor chemical/electroless approaches.

• Electrical or optical properties — specify conductive metals (Cu, Ni, Au) or reflective metals (Al, Ag) per spec.

• Volume and unit cost — electroplating and PVD scale well for high volumes; thermal spray is more flexible for small runs and repairs.

• Environmental & regulatory concerns — choose lower-VOC processes and manage waste streams from chemical baths responsibly.

Equipment and inspection

A modern metallizing line needs more than the deposition tool: degreasers, blasting booths, vacuum chambers, chemical baths, masking stations, and robust inspection tools (coating-thickness gauges, adhesion testers, profilometers, microscopes). For high-precision work we add metrology (CMMs) and community-standard test methods to demonstrate compliance. As your manufacturer and one-stop service provider, we integrate these capabilities into our factory flow so coatings are qualified as part of production.

Advantages, limits and realistic tradeoffs

Metallization delivers performance and aesthetics, but it isn’t a panacea:

• Advantages: improved wear, corrosion protection, conductivity, visual appeal, and the ability to metallize non-metal parts.

• Limitations: some processes need strict surface prep, high-cost vacuum systems, or can damage heat-sensitive parts. Thin coatings can’t substitute for bulk metal strength. Complex internal geometries can be hard to coat uniformly, and environmental controls are needed for chemical plating. Understanding these tradeoffs helps you pick the optimal supplier and process.

Typical applications and real-world examples

• Automotive: headlamp reflectors (PVD), trim components (electroless + plating), and galvanized chassis parts.

• Electronics: EMI/RFI shielding on plastic housings via electroless copper + nickel.

• Aerospace & energy: thermal-barrier and wear coatings via HVOF or plasma spray.

• Consumer products: decorative, durable finishes on appliances and cosmetic packaging using PVD or chrome plating.

• Packaging & film: metallized films for barrier packaging and reflectors.

Production timelines and costing

Process time varies: thermal spray jobs can be done in tens of minutes for small parts; PVD cycles typically run 30–120 minutes per batch; electroplating lines may require hours including pre-treatment. Cost drivers include equipment amortization, labor for surface prep, material usage, and inspection. For OEM work the right approach balances part function, expected volumes, and total cost of ownership — not just per-part price.

Quality control and supplier coordination

As a contract manufacturer and supplier partner, Topmetalstamping eliminates process gaps by offering integrated OEM service: design for manufacturability (DFM) guidance, metallization selection, pilot runs, and full production with inline QA. We document process parameters, run capability studies, and provide test reports (adhesion, thickness, corrosion) so your supply chain has traceable quality and predictable lead times.

Final thoughts — how we can help

If you’re deciding between plating, PVD, thermal spray, or electroless for a new product, let’s talk specifics. At Topmetalstamping we combine high-precision stamping, machining, and in-house surface treatment to deliver one-stop service for OEM programs. Tell us your substrate, performance targets, and volume, and our engineers will propose the most cost-effective metallization route — including supplier coordination, trial runs, and full production support.

Ready to evaluate metallization options for your parts? Contact our factory team for a free manufacturing review and feasibility quote — we’ll translate your product goals into a production-ready metallizing plan that meets technical and commercial targets.