Have you ever had a job stalled because a drawing called out the “old” alloy name while your supplier only knows the “new” one? At Topmetalstamping we see that slip-up all the time — and it adds cost, delay, and risk to production. That’s why we put together this practical, manufacturer-focused guide to aluminum and aluminum alloys: how old and new grade names map, what the common alloys actually do, heat-treatment essentials, and what to consider when you specify material for CNC machining or cast parts. If you’re an engineer, buyer, or product manager, read on — we’ll make alloy selection and supplier conversations simpler so your project moves fast and finishes right.

1 — Old vs. New Alloy Designations: quick translation keys

Standards and naming conventions for aluminum alloys have evolved. In some markets engineers still reference legacy license-plate style names (for example “LD30”) while suppliers and mills now use numeric designations such as 6061. Common translation examples you should know when communicating with a factory or supplier:

- 6061 is equivalent to the old LD30 designation — a go-to general-purpose, heat-treatable alloy.

- Heat-resistant wrought alloys like 2A02 / 2A12 map to older LY/ LY-style names in historical records.

- Many corrosion-resistant Al-Mg alloys (the 5xxx series) appear under LF or LFx legacy codes in older documentation.

When you prepare drawings or purchase orders, include both the modern numeric grade and any legacy name shown on older specifications. That single step helps your manufacturer, supplier, and shop floor avoid costly interpretation errors.

2 — Common alloys: properties and where we use them

Below are practical summaries of typical families, how they behave, and common applications we run every day in our factory.

Commercially pure aluminum (1xxx series: 1050, 1060, etc.)

- Key traits: Very high ductility and corrosion resistance, excellent electrical and thermal conductivity, cannot be strengthened by heat treatment.

- Use cases: Deep-drawn parts, gaskets, conductive components, and any application where forming and conductivity are more important than strength.

Al-Mn alloys (3xxx series, e.g., 3A21 / LF21)

- Traits: Good corrosion resistance, formability; not heat-treatable (strength gained by cold work).

- Use cases: Tanks, liquid containers, formed sheet applications and parts exposed to weather.

Al-Mg alloys (5xxx series, e.g., 5A02 / 5A03 / 5A05)

- Traits: Higher strength than 3xxx, excellent fatigue and corrosion resistance, weldable.

- Use cases: Marine hardware, tanks and pressure vessels, welded structural parts and automotive interior trim.

Duralumin and heat-treatable Al-Cu/Al-Mg-Si alloys (2xxx and 6xxx series — e.g., 2A12, 2A02, 6061)

- Traits: High strength when solution treated and aged (T6 etc.), can be vulnerable to stress-corrosion unless properly treated.

- Use cases: Aircraft structural components, high-load machine parts, forgings and extrusions where strength matters.

High-strength wrought alloys and super-duralumin (7xxx series — e.g., 7A03, 7A04)

- Traits: Ultra-high strength after aging, often used in aerospace. Requires rigorous processing and corrosion protection.

- Use cases: Landing gear, primary aircraft structure, high-stress structural parts.

Casting alloys (ZL / ZA series: e.g., ZL101, ZL105, ZL108)

- Traits: Optimized for castability and specific strength/temperature ranges; many can be heat treated (T5/T6) to improve performance.

- Use cases: Engine housings, pump casings, pistons (ZL108 common), structural castings with complex geometry.

3 — Heat treatment basics every buyer should require

Calling out a numeric alloy is only half the story — the temper (T-code) defines final performance. Here are practical rules of thumb we follow on the shop floor:

- T6 (solution treat + artificial aging): Solution treat at elevated temperatures (varies by alloy, typically in the 495–530 °C window for many 2xxx/6xxx alloys), quench rapidly, then age (e.g., ~160–180 °C for several hours depending on alloy) to develop peak strength. Require vendor process sheets and sample testing for critical applications.

- T5 (cooled and artificially aged): Common for castings and extrusions where a full solution cycle is not used; gives intermediate strength with simpler processing.

- Anneal: For 1xxx and non-heat-treatable alloys, annealing is used to maximize ductility for forming (typical ranges 350–500 °C depending on gauge and alloy).

- Quench timing and aging windows: For heat-treatable alloys, quench time (transfer to quench media) and aging schedule directly affect properties — specify acceptable ranges in purchase documents.

If you need parts that meet a specific tensile or fatigue spec, ask your supplier for a signed heat-treatment record and sample mechanical test reports (tensile, hardness, elongation). At Topmetalstamping we include process traceability and test reports as standard for high-precision orders.

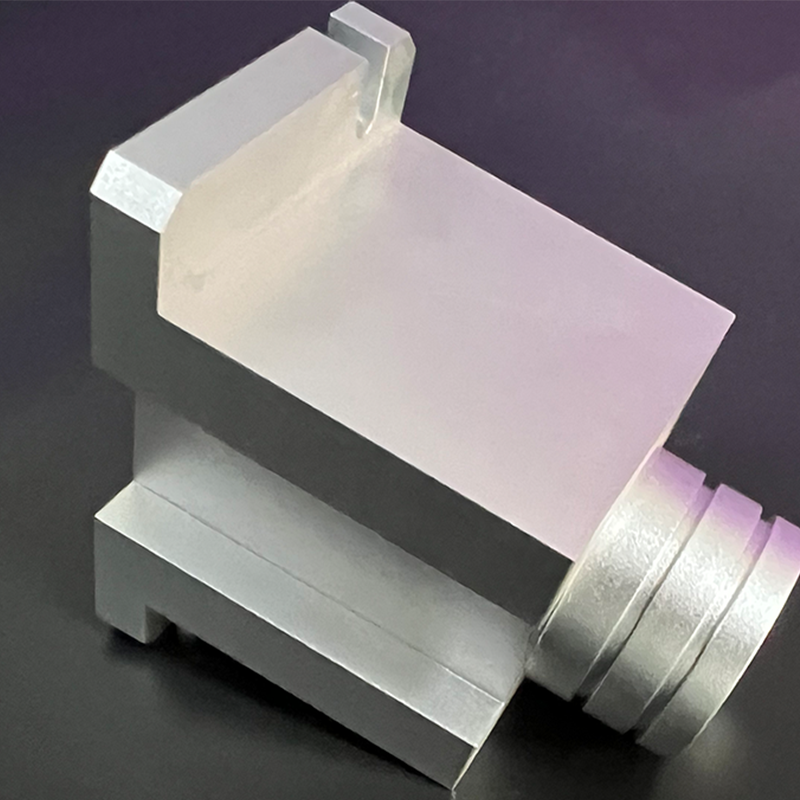

4 — What to consider when machining or designing for each alloy

- Machinability: 6xxx-series and 2xxx-series alloys machine well in the aged condition; pure Al (1xxx) machines poorly due to smearing and built-up edge. Specify temper and tool strategy with your manufacturer.

- Weldability: Al-Mg (5xxx) and many 1xxx/3xxx alloys weld well; many 2xxx and 7xxx alloys have limited weldability or require special filler metals. If you plan post-weld machining, tell your supplier early.

- Forming vs. strength tradeoff: For deep drawing pick a soft, highly ductile temper; for high load-bearing select a heat-treated alloy and acceptance temper (T6/T651, etc.).

- Thermal stability: High temperature applications require alloys like certain 2xxx or 7xxx grades — be explicit about service temperature in specs.

5 — Cast aluminum: choosing the right casting alloy

Casting alloys (ZL101, ZL104, ZL105, ZL108, ZL201, etc.) vary widely in fluidity, porosity tendency, heat-treatability, and mechanical performance:

- ZL101 / ZL101A: Good castability and corrosion resistance; widely used for housings and pump bodies.

- ZL105 / ZL106: Higher strength, heat-treatable — used in high-load castings.

- ZL108 / ZL109: Low density and excellent heat resistance — commonly selected for pistons.

- ZL201 / ZL205A: High-strength castings suitable for demanding aerospace/engine parts when properly heat treated.

Specify casting method and post-casting treatments on your drawing (e.g., sand casting vs. die casting; T5/T6 heat treatment) and require supplier proof (material certificates, metallography/porosity inspection, tensile test).

6 — Purchasing and supplier best practices

- Specify alloy and temper explicitly (e.g., 6061-T6), include old designation if your BOM uses legacy names.

- Call out critical mechanical properties and service conditions (temperature, environment, fatigue). Don’t rely on a generic grade callout.

- Require material certificates, heat-treatment records, and representative mechanical tests for critical orders.

- If surface quality or anodizing is required, define pre-treatment (e.g., etch, bright dip) and acceptable finish.

- Work with suppliers who offer one-stop service — tooling, heat treatment, machining, inspection and assembly — to reduce handoffs and specification drift. At Topmetalstamping our one-stop service simplifies logistics and improves first-pass yields.

7 — Final recommendations from the shop floor

Selecting the correct aluminum alloy and temper is as important as the CAD model. Use this checklist when preparing specs:

- Name the exact numeric alloy and temper. 2. Note any legacy/old designations for clarity. 3. State required tensile, yield, and elongation minima. 4. Call out heat-treatment process if needed. 5. Specify casting method and finish for cast parts. 6. Require supplier traceability and test reports.

At Topmetalstamping we turn specification clarity into parts that meet your performance expectations — every time. We combine engineering review, material sourcing from trusted suppliers, in-house heat treatment and precision CNC capability to deliver high quality, manufacturable components for the most demanding applications. If you want help translating legacy drawings, optimizing alloy selection for manufacturing, or quoting parts with full material traceability, contact us — we’re your factory partner from prototype through production.