Overview

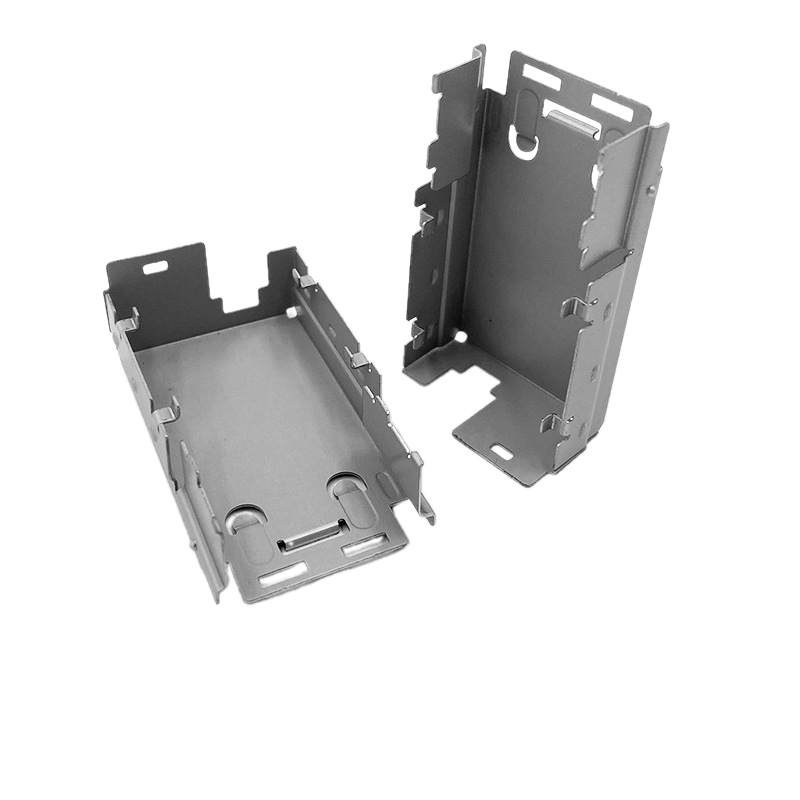

As a White Label Stainless Steel Metal Stamping Shielding Cover supplier, we provide high-precision, durable enclosures for EMI/RFI shielding in electronics. Made from SUS304/430 steel with advanced stamping and plating, our covers ensure protection, corrosion resistance, and seamless integration for PCBs and sensitive components.

Characteristics

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | White Label / OEM |

| Material | SUS304, SUS430, Cold Rolled Steel, Spring Steel |

| Thickness Range | 0.2 mm – 1.5 mm |

| Dimensions | Customized per drawing or 3D model |

| Surface Finish | Zinc Plating, Nickel Plating, Passivation, Conductive Coating |

| Shielding Effectiveness | Up to 60–100 dB (depends on material & design) |

| Tolerance | ±0.05 mm (tighter on mating edges & mounting holes) |

| Treatment Options | Electroplating, Powder Coating, EMI Gasket Integration |

| Process | Progressive Die Stamping, CNC Forming, Welding, Deburring |

| Certification | ISO 9001:2015, IATF 16949:2016, RoHS, REACH |

| Application | Electronics Enclosures, Communication Devices, Automotive ECUs, Medical Equipment |

| Sample | Available |

| MOQ | Flexible — based on design complexity |

Surface Treatment Options

-

Zinc Plating (Electro/Galvanized): Provides cost-effective corrosion resistance and a conductive surface suitable for grounding.

-

Nickel Plating: Offers superior corrosion and wear resistance with stable electrical conductivity for demanding environments.

-

Passivation (for Stainless Steel): Enhances the natural corrosion resistance of stainless steel and removes surface contaminants.

-

Conductive Epoxy or Paint: Applied for enhanced EMI shielding performance, especially on seams or joints.

-

Powder Coating: Available for aesthetic purposes and additional environmental protection where electrical contact is not required on the outer surface.

-

Tin Plating: Excellent solderability for covers requiring direct soldering to a PCB ground plane.

Quality Assurance

Our quality assurance system for shielding covers adheres to ISO 9001 and IATF 16949 standards. Each batch undergoes rigorous dimensional inspection using CMM and optical comparators to ensure precise fit. Functional validation includes continuity/resistance testing to verify electrical conductivity across seams. Critical performance is assessed through salt spray testing (ASTM B117) for corrosion resistance and, upon request, shielding effectiveness testing in certified labs. We also conduct burr inspection and flatness verification to guarantee safe handling and proper sealing with gaskets.

Factory Show

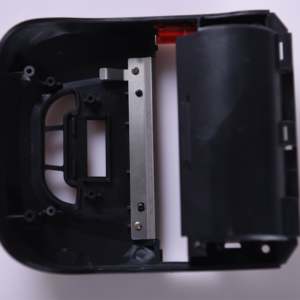

Our manufacturing facility is equipped with high-speed progressive stamping presses (25-200 tons) and precision CNC punching/forming centers for high-volume production of shielding covers. All stamping dies are engineered in-house using CNC machining and Wire EDM technology. We have integrated plating and coating lines for zinc, nickel, and passivation treatments. Post-processing includes automated deburring, laser welding for assemblies, and final inspection with automated optical systems. This vertical integration allows us to offer complete, reliable shielding solutions from prototype to mass production.

Reviews

There are no reviews yet.