Overview

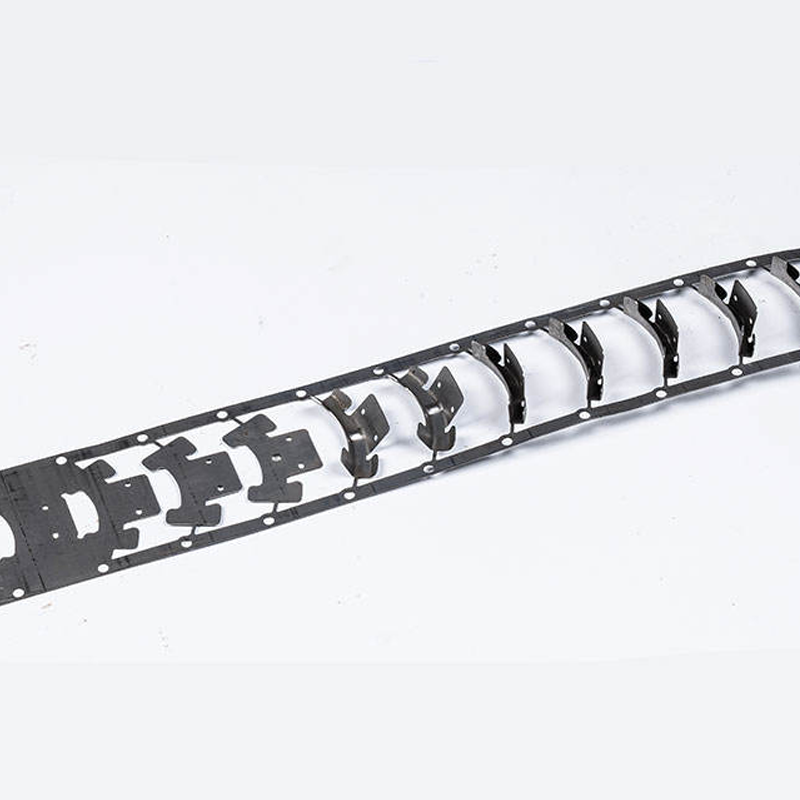

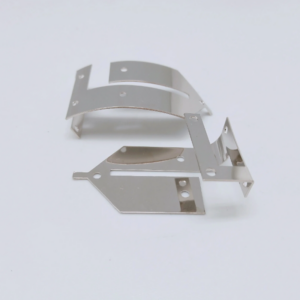

An OEM Progressive Die Stamping Steel Bracket for medical applications is a high-precision, complex component manufactured through multi-station progressive dies. Typically crafted from medical-grade stainless steels, this process ensures exceptional dimensional accuracy, structural integrity, and clean, burr-free edges critical for sterile environments. These brackets provide reliable mounting, structural support, and precise alignment in medical devices, diagnostic equipment, and life-support systems, where failure is not an option.

Characteristics

| Item | Details |

|---|---|

| Processing Type | High-Speed Progressive Die Stamping |

| Primary Material | Stainless Steel (304, 316, 316L), Spring Steel (1075, 301), Aluminum |

| Tolerances | ±0.02mm (Critical Features), ±0.05mm (Standard) |

| Material Thickness | 0.1mm – 3.0mm |

| Surface Finish | Deburred, Electro-polished, Passivated, Bead Blasted |

| Secondary Processes | CNC Tapping, Welding, Heat Treatment (Tempering) |

| Industry Application | Medical Device & Life Science Instrumentation |

| Mold Design | Custom Multi-Station Progressive Die |

| Drawing Formats | DXF, DWG, STEP, IGES, SolidWorks |

| Sample Lead Time | 10-15 Days (with soft tooling) |

| Production Lead Time | 25-35 Days (for hard tooling & batch) |

| Customization | Fully Customizable from Design |

| Packaging | Cleanroom Bags, ESD Trays, Vacuum Sealed |

| Certifications | ISO 13485, ISO 9001, Material Certs (RoHS, REACH) |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | High-Volume, Program-Based |

The Benefits of Bracket

-

Exceptional Precision & Consistency: Progressive dies perform multiple operations (piercing, bending, coining) in a single pass, guaranteeing micron-level repeatability across millions of parts, which is essential for device assembly and function.

-

High-Volume Cost Efficiency: Once the precision die is built, the per-part cost becomes extremely low, making it the most economical method for producing complex brackets at scale for the medical industry.

-

Superior Material Utilization & Strength: The process minimizes waste and preserves the metal grain structure, resulting in brackets with high strength-to-weight ratios and excellent fatigue resistance for dynamic applications.

-

Integrated Features & Complex Geometry: Allows for the incorporation of intricate features—such as locking tabs, threaded holes, and snap-fits—as part of the stamped form, reducing secondary operations and assembly steps.

-

Clean, Contaminant-Free Production: The stamping process, combined with proper post-processing (e.g., ultrasonic cleaning, passivation), produces parts that meet the stringent cleanliness requirements of medical devices.

Production Process

-

Design for Manufacturability (DFM) & Tooling Design: Engineers collaborate to optimize the part design for stamping and design a multi-station progressive die, simulating the forming process to prevent defects.

-

Precision Die Fabrication: The progressive die set is manufactured using high-precision CNC machining, Wire-EDM, and grinding from premium tool steels, ensuring longevity and accuracy.

-

High-Speed Stamping: Coils of certified medical-grade metal are fed into a high-tonnage stamping press. The progressive die forms the complete bracket through sequential stations in one continuous cycle.

-

In-Process Quality Monitoring: Automated vision systems and sensors monitor critical dimensions and detect defects in real-time during the high-speed stamping run.

-

Secondary Operations & Finishing: Parts may undergo tapping, heat treatment for spring properties, or precision welding. They are then cleaned, deburred, and receive specified surface treatments like electropolishing.

-

Stringent Quality Assurance & Documentation: 100% dimensional inspection, material certification review, and functional testing are performed. Full DHR (Device History Record) traceability is maintained per ISO 13485.

-

Cleanroom Packaging & Sterilization-Ready Packaging: Finished brackets are packaged in controlled environments using medical-grade packaging to preserve cleanliness and facilitate sterilization (EtO, Gamma) if required.

Medical Bracket Applications

-

Diagnostic & Imaging Equipment: Precision brackets for mounting sensors, optics, and moving components within MRI machines, CT scanners, and blood analyzers, requiring non-magnetic materials and vibration dampening.

-

Surgical & Handheld Tools: Structural supports and chassis components for powered surgical tools, endoscopes, and dental instruments, demanding lightweight, robust, and sterilizable designs.

-

Patient Monitoring & Life Support: Critical mounting frames and assemblies within ventilators, infusion pumps, and dialysis machines, where reliability and long-term durability are paramount.

-

Laboratory Automation: Robotic arm brackets, plate handlers, and instrument mounts in automated liquid handling and sample testing systems, requiring high precision and corrosion resistance.

-

Portable Medical Devices: Internal structural frames for handheld monitors and portable diagnostic devices, optimized for compact space, impact resistance, and weight reduction.

Our Factory

Our medical device manufacturing facility features a dedicated, climate-controlled stamping center equipped with high-speed progressive die presses (45 to 300 tons) and precision die maintenance workshops with CNC and Wire-EDM capabilities. We operate a Class 100k cleanroom for secondary assembly and packaging. Our quality assurance is anchored by an ISO 13485 compliant system, supported by a full-metrology lab with CMM, optical comparators, and advanced surface analysis equipment. From certified raw material sourcing to final cleanroom packaging, our integrated processes are designed to meet the exacting standards of the global medical device industry.

Reviews

There are no reviews yet.