Overview

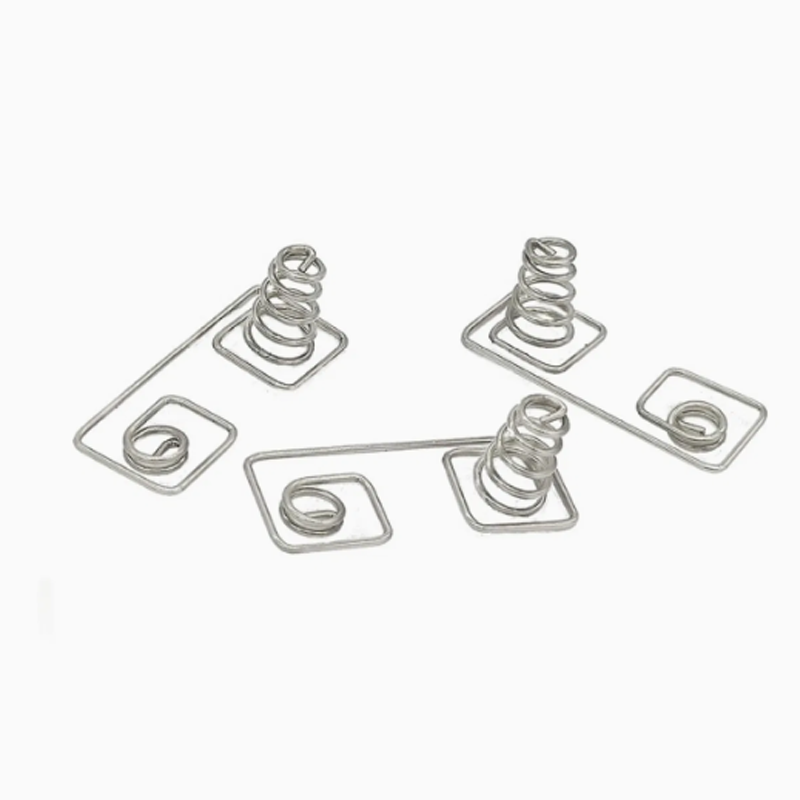

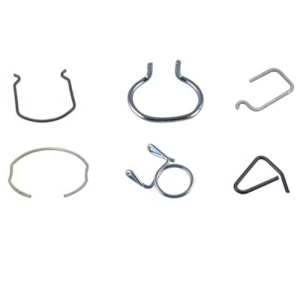

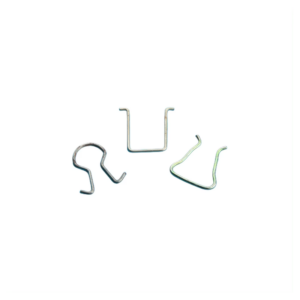

Our custom precision metal stamping spring contacts are engineered for critical electrical connections in battery modules and packs. Manufactured from high-performance alloys, they offer stable contact force, low resistance, and long-term reliability in demanding EV and energy storage applications. We provide full OEM solutions tailored to your specific electrical and mechanical requirements.

Characteristics

| Category | Details |

|---|---|

| Application | Battery Modules & Packs, BMS Connections |

| Production Process | Precision Progressive Die Stamping & Forming |

| Primary Material | Beryllium Copper (C17200), Phosphor Bronze (C5191, C5210), High-Carbon Spring Steel |

| Contact Finish | Gold Plating, Silver Plating, Nickel Plating, Tin Plating |

| Contact Resistance | < 5 mΩ (customizable, depending on design & plating) |

| Initial Contact Force | 50g – 500g (Customizable) |

| Certification | IATF 16949, ISO 9001:2015 |

| Brand | OEM |

| Shape & Design | Fully Custom (U-Shape, Cantilever, Dome, Multi-Finger) |

| Special Features | OEM Design, Heat Treatment for Spring Properties |

| Lead Time | 25-30 Days |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | High-Volume Capable |

Production Process

-

Material Selection & Blanking: High-conductivity, high-elasticity alloy strips (e.g., BeCu, Phos Bronze) are selected and precision blanked.

-

Progressive Stamping & Forming: The strip feeds through a multi-station progressive die, performing piercing, bending, coining, and forming the intricate spring geometry in one continuous process.

-

Heat Treatment (Aging/Tempering): For materials like BeCu, a controlled heat treatment process is applied to achieve the specified spring temper, hardness, and stress relaxation resistance.

-

Deburring & Surface Preparation: Parts are tumbled or chemically deburred to remove sharp edges, ensuring safety and preparing the surface for plating.

-

Precision Plating: Electroplating (Gold, Silver, Nickel, or Tin) is applied to critical contact surfaces to ensure low and stable contact resistance, solderability, and corrosion protection.

-

100% Functional & Dimensional QA: Every contact undergoes automated optical inspection (AOI). Sample batches from each lot are tested for contact force vs. deflection curve, electrical resistance, and plating thickness.

-

Packaging: Contacts are packaged in anti-static, compartmentalized trays or reel-to-reel packaging to prevent damage and facilitate automated assembly.

Why Choose Us?

-

Expertise in High-Performance Spring Contact Design: Our engineering team specializes in designing and manufacturing contacts that balance electrical performance, mechanical life, and force requirements specific to battery interconnection challenges.

-

Vertical Integration from Die to Delivery: We design and build our own precision progressive dies in-house, allowing for complete control over quality, rapid prototyping, and design optimization for manufacturability and cost.

-

Stringent Quality Focused on Electrical Reliability: Adhering to IATF 16949 standards, our process includes SPC monitoring and critical electrical/mechanical testing to guarantee performance consistency in safety-critical applications.

-

Comprehensive Testing & Validation Support: We provide full test reports (force-deflection, contact resistance, plating thickness, salt spray) with initial samples and production batches, supporting your product validation process.

-

Proven Partner for Automotive & Energy Sectors: Our experience in supplying mission-critical components for EVs and储能 systems makes us a reliable partner for your battery pack supply chain.

Factory Show

Our dedicated stamping facility is equipped with high-precision, high-speed progressive stamping presses and precision slide forming machines. We operate an in-house tool and die shop with CNC, Wire-EDM, and grinding centers for die manufacturing and maintenance. A controlled-environment plating line handles selective and reel-to-reel plating. Our quality lab is equipped with micro-ohm meters, digital force testers, coating thickness gauges (XRF), and salt spray test chambers. Operating under an IATF 16949 certified system, we ensure the production of reliable, high-performance spring contacts for the most demanding applications.

Reviews

There are no reviews yet.