Description:

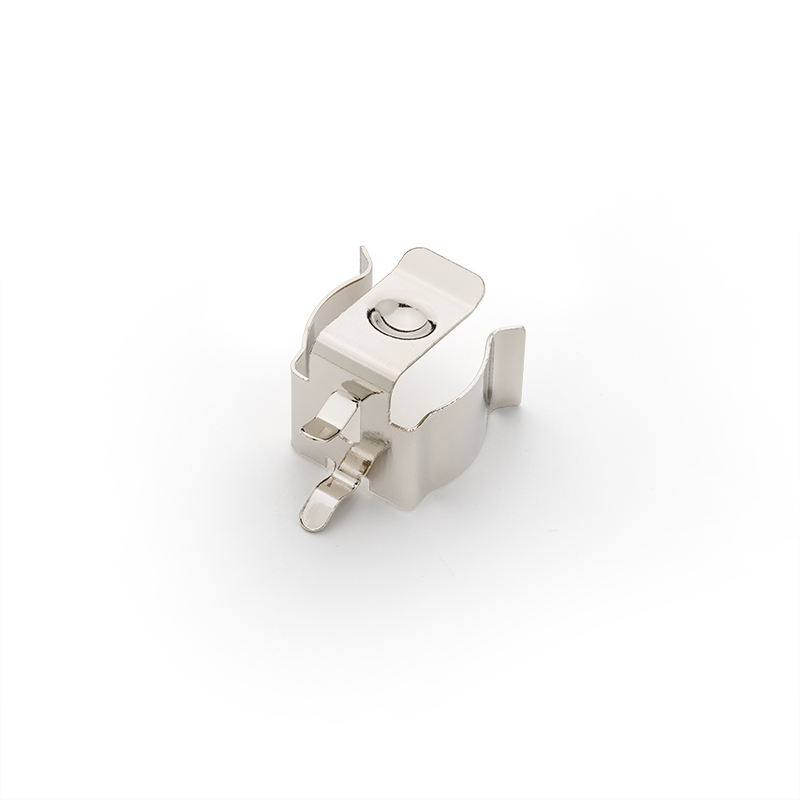

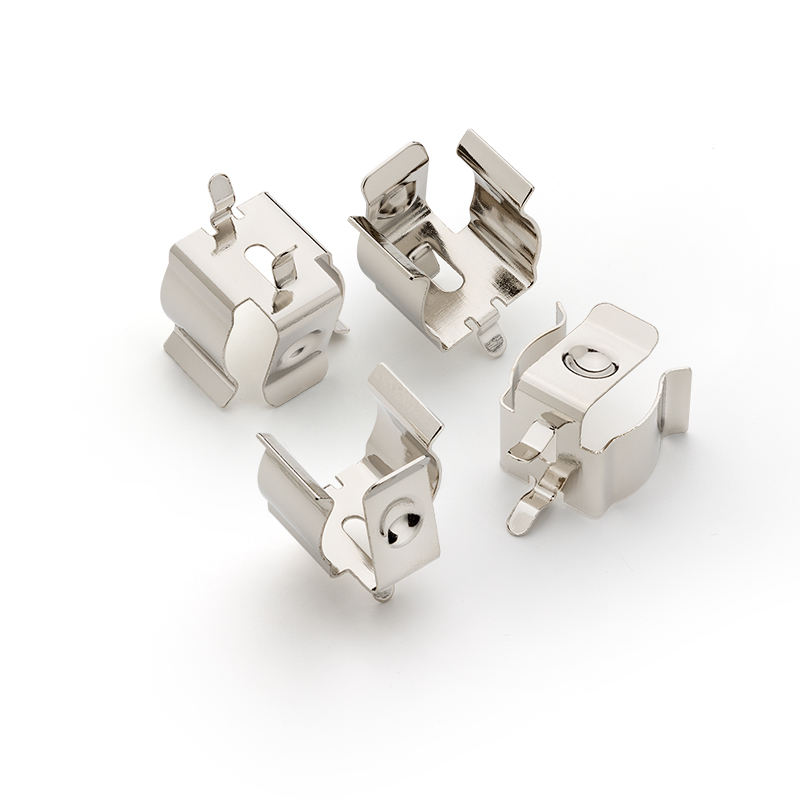

Our custom metal stamping battery holder clips are precision-engineered for secure electrical contact and reliable battery retention. Manufactured from high-conductivity spring steel with selective plating, they ensure optimal performance in consumer electronics, medical devices, and industrial equipment.

Features:

| Basic Info | Specification |

|---|---|

| Application | Consumer Electronics, Medical Devices, IoT Gadgets, Industrial Controls |

| Process Type | Progressive Die Stamping & Forming |

| Design Standard | Customer 2D/3D Drawing |

| Installation | SMT or Through-Hole |

| Certification | RoHS, REACH Compliant |

| Brand | OEM |

| Material | Spring Steel (SK, SUS), Phosphor Bronze, Beryllium Copper |

| Surface Finish | Nickel Plating, Tin Plating, Selective Gold Plating |

| Cycle Time | High-Speed Production (MS per part) |

| Lead Time (Sample) | 10-15 days |

| Dimension Tolerance | ±0.05mm (Critical Contact Points: ±0.03mm) |

| Contact Resistance | <20 mΩ (customizable) |

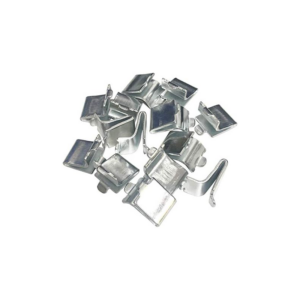

| Transport Package | Anti-Tarnish Bags, Reels (for SMT), Cartons |

| Specification | Fully Custom (AA, AAA, Coin Cell, Li-Po Custom) |

| Trademark | Customizable |

| Origin | Xiamen, China |

Advantages of Metal Stamping Battery Holder Clips:

-

Secure Retention & Excellent Electrical Contact: Precision-formed spring tension ensures batteries remain firmly in place during movement while maintaining low-resistance electrical connections for consistent power delivery.

-

High Reliability & Long Cycle Life: Made from high-cycle spring materials, our clips are designed to withstand thousands of insertion/removal cycles without losing their mechanical or electrical properties.

-

Optimized for Automated Assembly: Consistent dimensions and packaging options (tape-and-reel, blister packs) make our clips ideal for high-speed PCB assembly (SMT) or automated final product assembly.

-

Corrosion Resistance & Durability: Selective plating (e.g., nickel on spring arms, gold on contact points) protects against oxidation and ensures long-term reliability in various environmental conditions.

-

Design Flexibility & Customization: We provide full OEM support to design clips for any battery type, form factor, and mounting requirement, including custom shapes for space-constrained applications.

Production Process of Metal Stamping Battery Clips:

-

Design & DFM Analysis: Our engineers review your specifications, providing Design for Manufacturability (DFM) feedback on material thickness, bend radii, and stamping feasibility to optimize cost and performance.

-

Progressive Die Design & Fabrication: A custom multi-station progressive die is designed and precision-machined using CNC and Wire EDM to form, pierce, and blank the clip from a continuous metal strip.

-

High-Speed Precision Stamping: Coiled metal is fed through the die in a high-speed stamping press, producing a complete, formed clip with each press stroke, ensuring volume efficiency and consistency.

-

Secondary Finishing & Plating: Stamped clips undergo tumbling or vibratory deburring. They are then plated via reel-to-reel or barrel plating processes to apply the specified finish (Ni, Sn, Au) for conductivity and protection.

-

Quality Inspection & Testing: Samples from each batch are inspected under microscopes for dimensional accuracy. Critical performance tests include spring force measurement, contact resistance checks, and solderability tests.

-

Packaging for Automated Handling: Finished clips are packaged per customer requirement—loaded onto SMT reels, packed in anti-static bags, or sorted into blister packs—ready for integration into your production line.

Our Advantages:

-

Expertise in Precision Electronic Contacts: We specialize in the design and mass production of small, intricate metal contacts and springs, with a deep understanding of electrical and mechanical requirements.

-

Integrated In-House Tooling & Plating: Controlling the entire process from die design and stamping to plating in our own facility ensures tight quality control, faster turnaround, and cost efficiency.

-

Focus on Functional Performance: Our engineering prioritizes the real-world function of the clip—retention force, electrical path integrity, and durability—over just dimensional conformance.

-

Scalable Solutions from Prototype to Mass Production: We support projects at any scale, from rapid prototyping using short-run tools to high-volume manufacturing with dedicated, high-speed progressive dies.

Reviews

There are no reviews yet.