Overview:

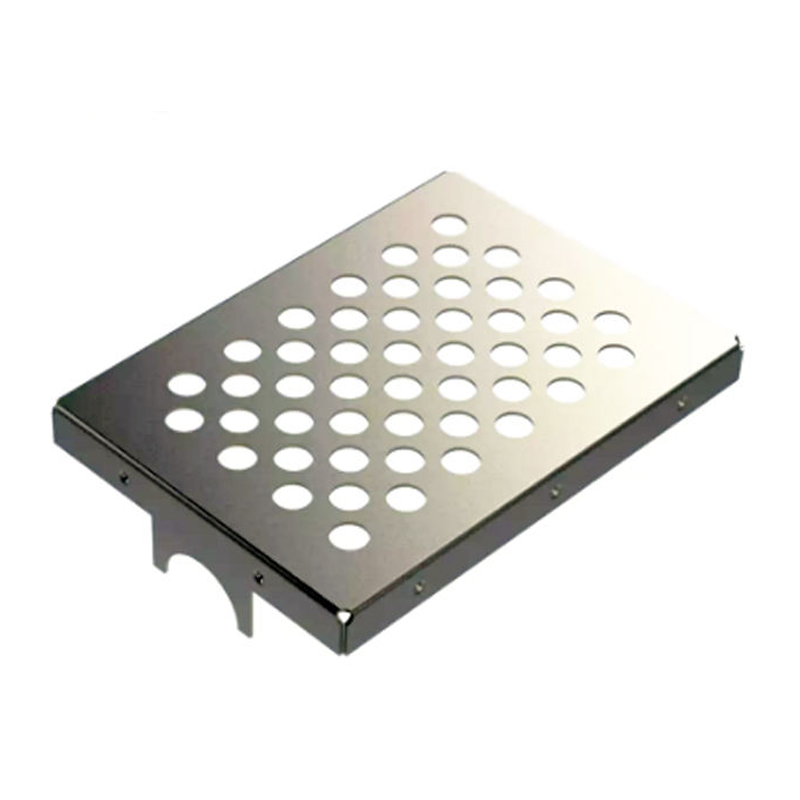

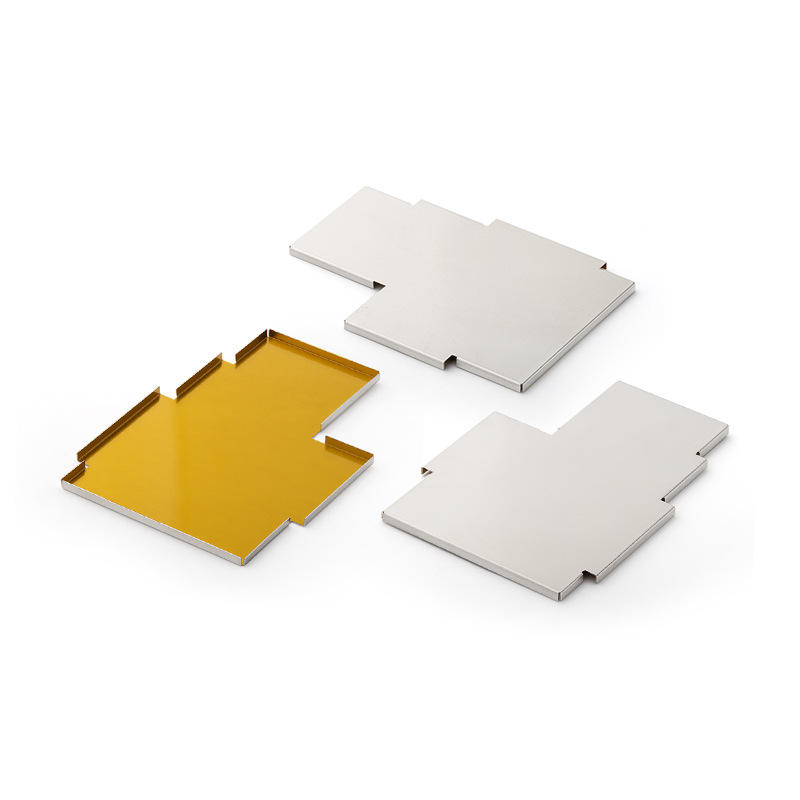

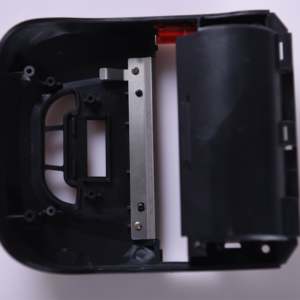

We specialize in custom stainless steel deep-drawn shields for PCB circuit board protection. Our precision-formed enclosures provide superior EMI/RFI shielding, mechanical durability, and thermal management. Customizable for exact fit and performance in electronics applications.

Details:

| Category | Details |

|---|---|

| Materials Available | Stainless Steel (SUS304, SUS430, SS 301), Aluminum, Cold Rolled Steel (SPCC) |

| Surface Treatment | Nickel Plating, Tin Plating, Passivation, Conductive Coating, Powder Coating |

| Specification | OEM, per Client Drawing & Sample |

| Certificates | ISO9001:2015, RoHS, REACH |

| Tolerance | ±0.05mm to ±0.15mm (Form Dependent) |

| Software Used | AutoCAD, SolidWorks, Pro/E |

| Size | Fully Customizable |

Production Process:

-

Tooling & Prototyping: Design and manufacture custom deep drawing progressive dies and blanking tools. Create prototypes for dimensional and fit verification on target PCBs.

-

Material Blanking: Precision blank pre-finished stainless steel sheets to the required size and shape for the drawing process.

-

Deep Drawing & Forming: Utilize multi-stage deep drawing presses to gradually form the flat blank into a seamless, three-dimensional shield with precise depth and wall thickness.

-

Trimming & Piercing: Trim the drawn part to final height and pierce any required mounting holes, ventilation slots, or connector openings.

-

Secondary Processes: Perform spot welding for multi-part assemblies, tapping, or deburring to ensure smooth edges and readiness for assembly.

-

Surface Treatment: Apply specified finish—such as nickel plating for solderability and shielding, or passivation for corrosion resistance.

-

Quality Inspection & Packaging: Conduct final inspections for dimensions, visual defects, and shielding effectiveness (as required). Package with protective films to prevent scratching.

Our Advantages:

-

Superior EMI/RFI Shielding Effectiveness: Our seamless deep-drawn construction provides a continuous conductive enclosure, effectively containing electromagnetic interference and protecting sensitive PCB components.

-

Robust Mechanical Protection & Durability: Made from high-strength stainless steel, our shields offer excellent resistance to impact, vibration, and corrosion, ensuring long-term reliability in demanding environments.

-

Precision Engineering for Perfect Fit: Advanced deep drawing and tooling techniques allow for complex geometries with tight tolerances, guaranteeing a precise, secure fit over the PCB assembly without interference.

-

Effective Heat Dissipation & Thermal Management: The metal shield acts as a heat spreader, and we can design integrated features (fins, vents) or select materials to optimize thermal performance for your application.

-

Full Customization & Design Support: We provide comprehensive OEM services, from initial design consultation to prototyping and volume production, tailoring every aspect (material, finish, form factor) to your needs.

-

Quality Assured for Critical Applications: Our ISO-certified manufacturing process includes strict dimensional and material controls, ensuring every shield meets the high-reliability standards required for telecommunications, automotive, and industrial electronics.

Factory Show:

Our manufacturing facility is equipped with high-tonnage mechanical and hydraulic deep drawing presses capable of handling multi-stage progressive forming. We maintain an in-house tool and die shop with CNC machining centers and wire EDM for precision die manufacturing. Dedicated welding stations and automated plating lines support secondary operations. Our quality control department utilizes CMMs, profile projectors, and salt spray test chambers to validate dimensional accuracy, surface finish durability, and corrosion resistance, ensuring the delivery of high-performance shielding solutions.

Reviews

There are no reviews yet.