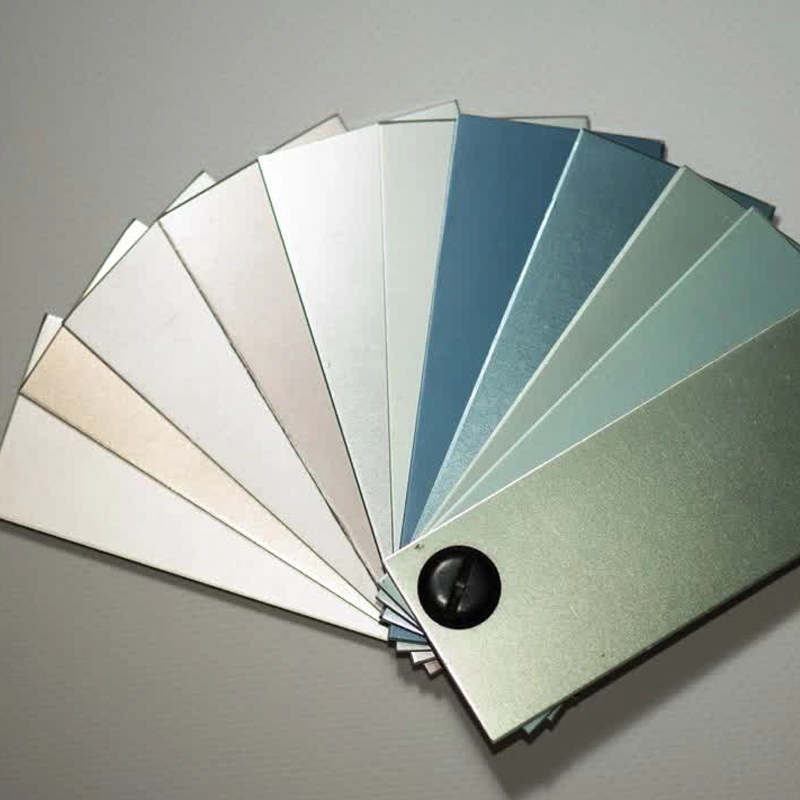

At Topmetalstamping, a precision manufacturing partner offering turnkey finishing and assembly for custom metal stamping parts, we help engineers and procurement teams weigh the trade-offs between anodizing and powder coating for aluminum. Both finishes are industry-proven, but they serve different objectives—appearance, corrosion protection, wear resistance, electrical properties, and downstream processing. This guide gives practical, B2B-focused guidance so you can pick the right finish for your parts and volumes, and understand implications for OEM service and one-stop supply.

Is it better to powder coat or anodize aluminum?

Short answer: it depends on your priorities. Choose anodizing when you need a thin, integrated oxide layer with excellent wear resistance, color stability (clear or dyed), and thermal/ electrical behavior. Choose powder coating when you want a thicker, visually uniform, and reparable paint-like finish that hides surface defects and offers a wide range of colors and textures.

Understanding the Processes

Anodizing is an electrochemical process that grows a controlled oxide layer on aluminum. Typical decorative anodize thickness is 5–25 µm; hardcoat or wear-resistant anodize can reach 25–100+ µm. The oxide is integral to the substrate (not a film) and can be dyed and sealed. Anodize improves surface hardness and provides a natural, matte-to-gloss finish.

Powder coating applies a dry thermoset powder (epoxy, polyester, or hybrid) that is electrostatically sprayed, then baked to form a continuous polymer film. Typical film thickness ranges 40–150 µm (or higher). Powder coats offer excellent color options, textures, and superior hiding ability for surface imperfections.

What is the downside of anodized aluminum?

Key Limitations to Consider

- Limited thickness for corrosion barrier: decorative anodize is thin and, if not sealed properly, is less protective in aggressive chloride or marine environments compared to heavy barrier coatings.

- Porosity: the anodic film is porous before sealing—unsealed porous layers can permit staining or underfilm corrosion in harsh chemistries.

- Color range constraints: although dyes expand options, very bright, saturated colors and metallic effects are harder to achieve than with powder.

- Repairability: scratched anodize is not easily touch-repaired; restoration often requires re-finishing the entire part.

- Masking and adhesion: anodize can make paint/plating adhesion variable unless properly pretreated; some machining or secondary operations may remove the anodic layer and require rework.

- Cost for heavy anodize: thick hardcoat anodize (for wear) is more expensive and may add lead times.

Does anodizing make aluminium parts stronger?

Surface Hardness vs. Structural Strength

Anodizing increases surface hardness and wear resistance—hardcoat anodize can produce a substantially harder surface than bare aluminum (useful for sliding parts, bushings, or wear faces). However, anodizing does not increase the structural (bulk) strength of the aluminum substrate. It is a surface treatment; design decisions for structural load capacity should be made independently from anodize selection. Also note that very thick anodize layers can change tight-tolerance fits and slightly affect dimensions — design allowances or post-anodize machining may be needed.

What are the downsides of powder coating?

Key Limitations to Consider

- Film thickness and dimensional change: powder coatings are thicker and can interfere with tight fits, threads, and press tolerances unless compensated in the stamping/tooling.

- Potential for chipping and wear: in high-impact or sliding wear applications, powder coat can chip or abrade; a hard anodize or tribological coating may be preferable.

- Thermal and chemical limits: different resins have different temperature and chemical resistance—epoxy powders have poor UV stability, polyester powders are better outdoors but not immune to strong solvents.

- Pretreatment sensitivity: long-term corrosion resistance depends on pretreatment (conversion coating, e.g., chromate or trivalent) and proper application; poor pretreatment produces early failures.

- Repair aesthetics: touch-up is possible but matching texture/gloss perfectly can be difficult.

Conclusion

Neither finish is categorically better—each has strengths:

- Choose anodizing when you need integrated surface hardness, superior wear resistance, good heat/UV stability, electrical/thermal considerations, or a slim, refined aesthetic (clear or subtle dyes). Hardcoat anodize is excellent for sliding parts and exposed mechanical surfaces.

- Choose powder coating when color variety, texture, impact resistance (cosmetic), corrosion protection over complex shapes, and easier repairability are priorities—especially for enclosures, consumer products, and parts where hiding tooling marks matters.

For many programs the optimal approach is hybrid: anodize critical wear surfaces or mating faces and powder coat housings or visible panels. With custom metal stamping parts, allowance planning for coating thickness is essential. At Topmetalstamping we offer full OEM service and one-stop service—from stamping and forming to pretreatment, anodize or powder-coat finishing, assembly, and packaged delivery—so you get parts specified to function and fit out of the box.

Need help choosing or specifying finishes for your aluminum parts? Contact Topmetalstamping for a DFM review, coating thickness allowances, comparative cost and durability estimates, or a sample production run. We’ll partner with you to select the finish that best balances performance, cost, and manufacturability.