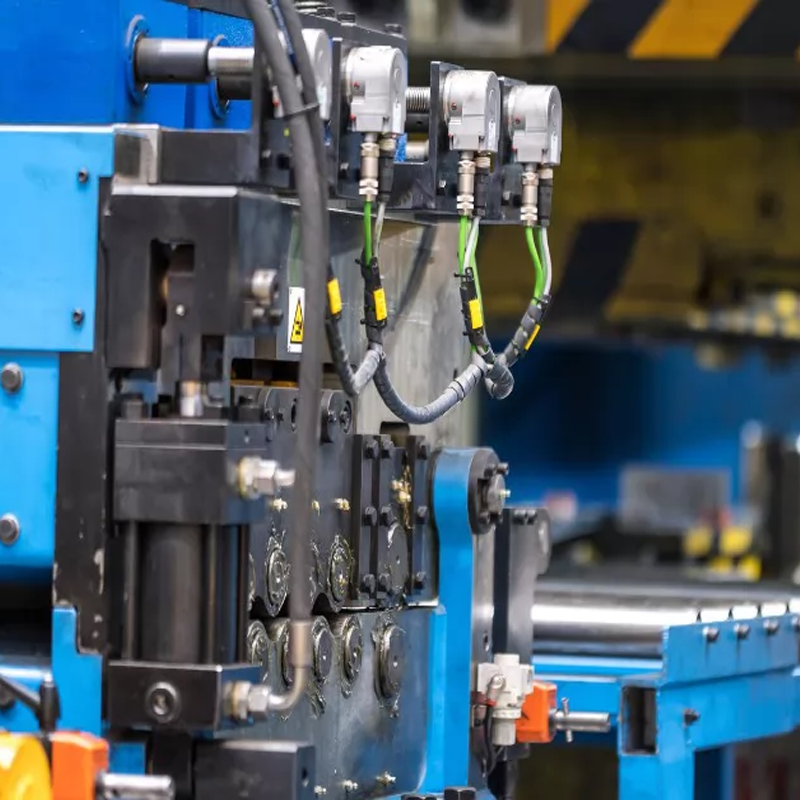

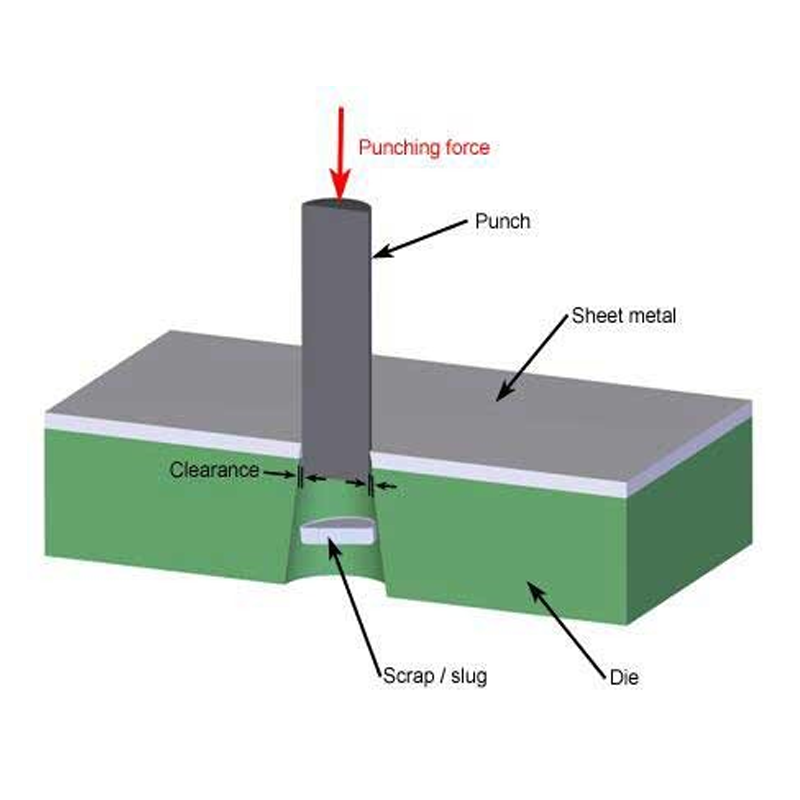

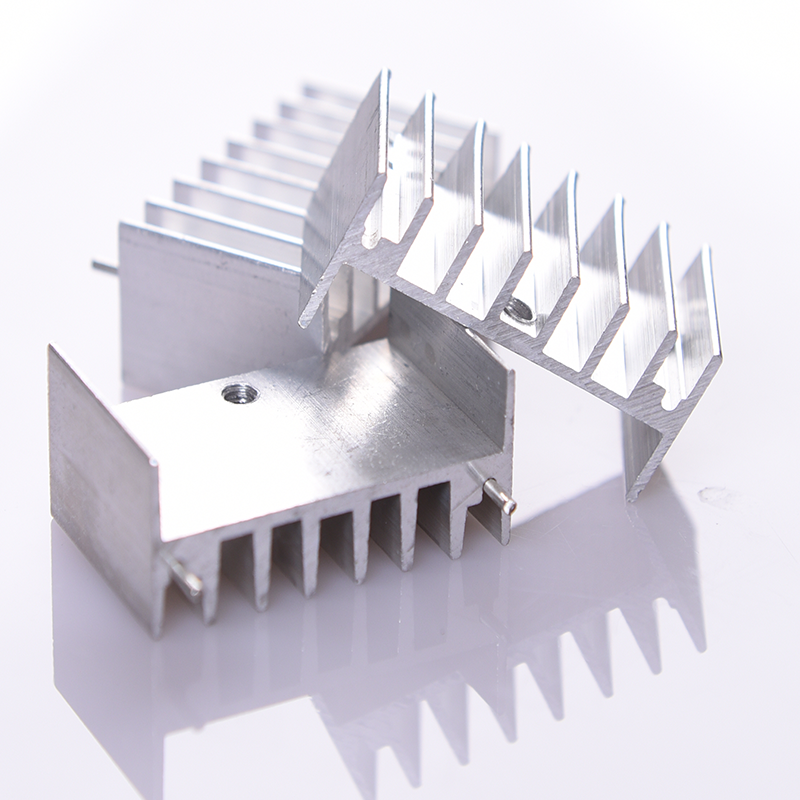

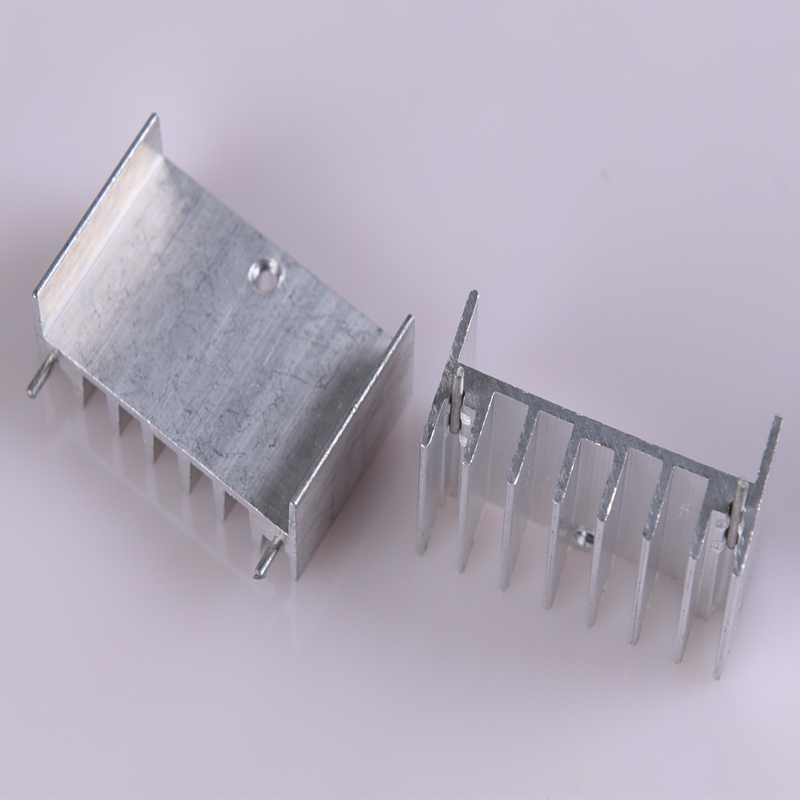

At Topmetalstamping, we specialize in the design and production of high-precision reel-to-reel terminals and contacts, providing industry-leading solutions for electrical applications. These custom-made terminals and contacts are crucial components in a wide variety of industries, including automotive, electronics, telecommunications, and industrial automation. Our cutting-edge production capabilities allow us to deliver precision parts that are essential […]