In the world of product development, the ability to create functional prototypes is crucial, especially when working with materials that must meet stringent performance criteria. Metal prototyping plays an essential role in industries such as aerospace, automotive, medical devices, and consumer electronics. At Topmetalstamping, we specialize in providing high-quality, high-precision metal prototypes to clients looking to test their designs before committing to full-scale manufacturing.

Metal prototypes allow engineers to evaluate critical factors such as material strength, durability, and compatibility with other components. The feedback obtained from testing metal prototypes can significantly enhance the design process, ultimately leading to better products and more efficient manufacturing processes. In this guide, we will delve into the metal prototyping process, its applications, and how it benefits various industries.

Why Do You Need a Metal Prototype?

The development of metal prototypes is a fundamental step in the engineering and manufacturing process. It allows engineers to validate design concepts, assess functionality, and test material properties before committing to mass production. Whether for an aerospace component, a medical device, or an automotive part, testing with a metal prototype ensures that the final product meets all required standards and performs under real-world conditions.

At Topmetalstamping, we understand the importance of producing metal prototypes with the highest quality and precision. Our one-stop service covers the entire prototyping and manufacturing process—from design to production, ensuring that you receive customized, high-precision prototypes that meet your specific needs.

Key Reasons to Choose Metal Prototyping

1. Durability Testing

Testing the durability of a design before full-scale production is crucial, especially in industries such as aerospace, automotive, and medical devices. Metal prototypes allow engineers to assess the material’s strength, thermal resistance, and structural integrity under operational conditions. This testing is essential to detect design flaws early in the process, saving time and money in the long run.

Engineers often apply Hooke’s Law and Von Mises stress theory to analyze the mechanical strength and failure points of a material under complex loading. These simulations help ensure that the final product can withstand the stresses and strains it will face in its intended application.

2. Investor and Client Demonstration

A metal prototype provides a tangible model that helps investors, clients, and stakeholders visualize the final product before full production begins. This hands-on demonstration allows for better understanding and approval of the design, ensuring that all expectations are met.

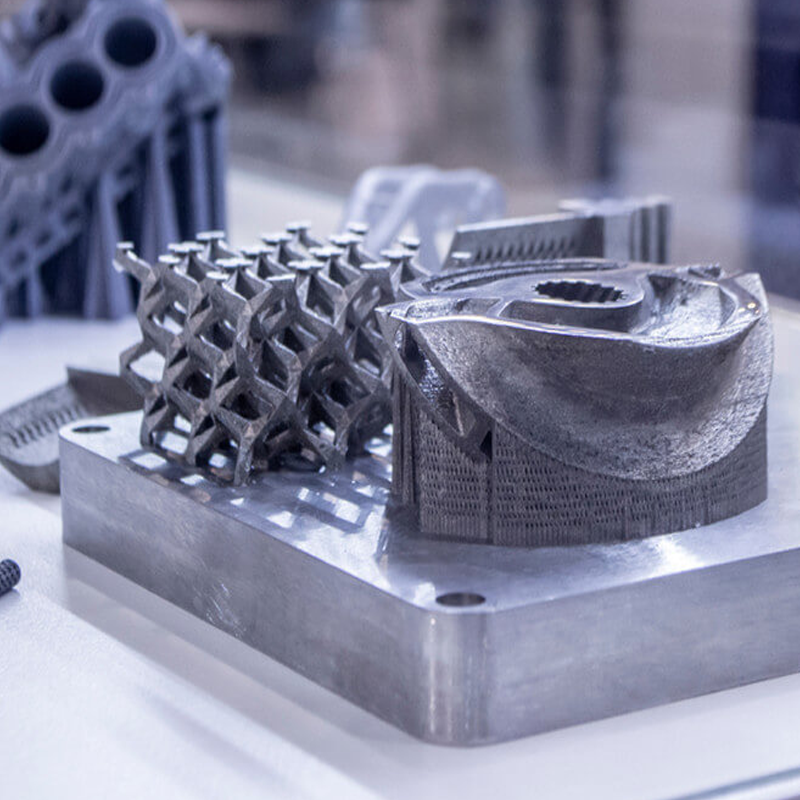

At Topmetalstamping, we use CNC machining, precision casting, and metal 3D printing to produce metal prototypes that meet strict tolerance levels. These methods ensure that the prototype accurately represents the final product in terms of both functionality and aesthetics. Additionally, we conduct extensive testing using tools like surface profilometers and CMMs (Coordinate Measuring Machines) to ensure that the prototype meets quality standards.

3. Regulatory Compliance

In many industries, including aerospace, automotive, and medical, products must meet specific regulatory standards. Metal prototypes are essential for ensuring that the final product complies with these regulations.

We perform various tests on our metal prototypes, including tensile testing, hardness testing, and material analysis using XRF analyzers to confirm the alloy composition. Our team ensures that all prototypes meet industry-specific standards such as AS9100 (for aerospace), IATF 16949 (for automotive), and ISO 13485 (for medical devices).

Applications of Metal Prototypes

Aerospace Industry

Metal prototypes are vital in aerospace manufacturing, where components such as engine parts, structural brackets, and airframe components need to be tested for durability and high-performance criteria. These components are often subject to extreme temperatures and mechanical stress, making metal prototyping essential for testing and validation.

At Topmetalstamping, we use advanced techniques like Finite Element Analysis (FEA) to simulate mechanical fatigue and stress. We also use ultrasonic testing to inspect turbine blades made from Inconel 718 and Ti-6Al-4V, ensuring that the components meet rigorous performance standards before they are put into production.

Automotive Industry

The automotive industry relies heavily on metal prototyping to create custom engine parts, chassis components, and gears. Metal prototypes allow engineers to test components in real-world conditions, including stress, fatigue, and durability tests.

We support the automotive sector with high-precision prototyping methods such as CNC machining and metal casting to ensure that every part meets design specifications. We also employ stress testing and fatigue analysis to assess the lifespan and reliability of automotive components.

Medical Industry

In the medical industry, precision is key. Metal prototypes are used to create surgical tools, orthopedic implants, and prosthetic devices that require both functionality and biocompatibility. We work closely with medical device manufacturers to produce prototypes that meet strict safety and regulatory standards.

Through electrochemical analysis and corrosion resistance testing, we ensure that our prototypes are suitable for medical applications. Our expertise in metal 3D printing and CNC machining allows us to create highly precise components for the medical field.

Heavy-Duty Industrial Applications

Heavy-duty industries require metal prototypes for parts that will undergo mechanical load testing and operate in harsh environments. Engineers use these prototypes to evaluate how components will perform under high-stress conditions and extreme temperatures.

At Topmetalstamping, we employ techniques like torsion testing and fatigue testing to assess the durability of heavy-duty parts. We also use non-destructive testing (NDT) methods like ultrasonic testing and eddy current testing to detect internal flaws in components.

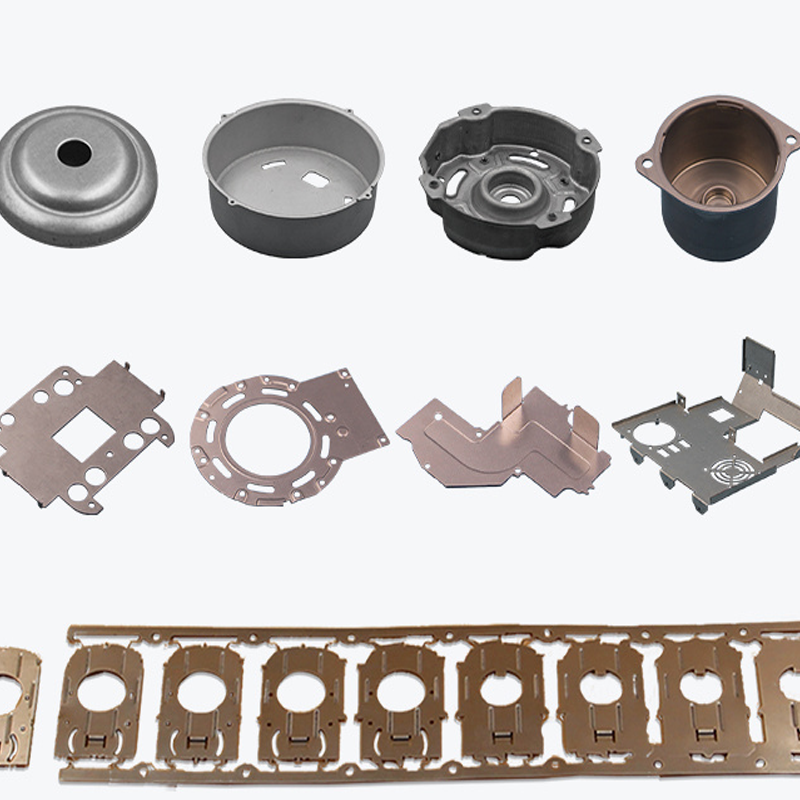

Consumer Electronics

In consumer electronics, metal prototypes are used to create components such as heat sinks, enclosures, and frames for mobile devices and laptops. The goal is to ensure that these components are lightweight, durable, and able to dissipate heat effectively.

We use infrared thermography to analyze heat dissipation and perform thermal conductivity tests to optimize designs for electronics. Our metal prototyping services help create functional and aesthetically pleasing components for the electronics industry.

Steps to Create a Metal Prototype

The process of creating a metal prototype involves several key steps:

- Define Goals and Requirements: Engineers define the prototype’s purpose and performance criteria, considering factors like mechanical testing, temperature resistance, and fit quality.

- 3D Design and Modeling: Using CAD software, engineers create detailed 3D models of the prototype, considering manufacturability and material specifications. The design is then refined to meet the necessary tolerances and performance standards.

- Material Selection: Engineers select the appropriate material for the prototype, considering factors like strength, thermal conductivity, corrosion resistance, and weight.

- Choose a Prototyping Method: Depending on the design complexity and production volume, different prototyping methods are used, such as CNC machining, metal 3D printing, or casting.

- Surface Finishing: Surface finishing methods like anodizing, electropolishing, and powder coating are applied to improve the durability and appearance of the prototype.

- Testing and Refinement: Prototypes undergo testing for mechanical strength, temperature resistance, and fit. Any necessary design adjustments are made based on test results.

Conclusion

Metal prototyping is an essential process for validating designs and ensuring product performance across industries such as aerospace, automotive, medical, and consumer electronics. At Topmetalstamping, we provide high-precision metal prototypes that meet the highest quality standards. Our one-stop service includes design, prototyping, and mass production, ensuring that your product is ready for the market faster and more efficiently.

If you’re looking for a reliable supplier with expertise in metal prototyping, contact us today to learn more about our custom services and how we can support your manufacturing needs. Whether you’re working on a small-scale prototype or preparing for mass production, Topmetalstamping is here to help you every step of the way.