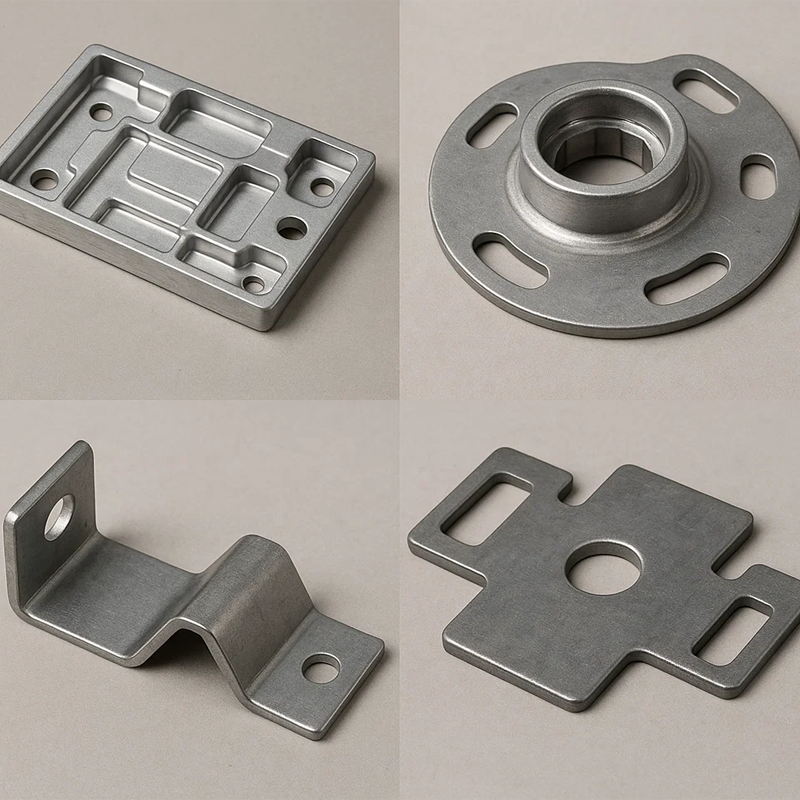

In the world of manufacturing, the metal stamping industry serves as a vital component across numerous sectors. Whether it’s automotive, aerospace, electronics, or medical, metal stamping parts are essential for creating precise, durable, and reliable components. Each industry has its own set of requirements when it comes to the precision, material, and durability of the stamped parts. These criteria are shaped by the unique needs of each sector, and understanding these specifications is crucial for manufacturers to meet the high expectations of their customers.

At Topmetalstamping, we are well-versed in catering to the diverse demands of various industries, providing customized solutions for metal stamping that address precision, material selection, and durability. In this blog, we will explore how the requirements differ from one industry to another, and how our expertise helps customers ensure that their products meet or exceed industry standards.

1. Automotive Industry: Precision and Durability for Safety and Performance

The automotive industry is perhaps one of the most demanding sectors when it comes to metal stamping parts. Precision is paramount, as automotive parts must fit together seamlessly to ensure the functionality and safety of the vehicle. For example, parts such as body panels, brackets, and chassis components must adhere to tight dimensional tolerances to maintain the vehicle’s structural integrity.

Key Requirements in Automotive Metal Stamping:

- Precision: Parts must fit together accurately for proper assembly and performance. Tolerances are typically tight, especially for components like suspension parts or structural elements.

- Material Selection: Automotive parts are usually made from high-strength steel or aluminum alloys, as these materials offer both durability and lightweight properties.

- Durability: Parts must withstand harsh conditions, including high temperatures, mechanical stress, and corrosion. For instance, components exposed to high levels of friction, such as engine parts, require materials that resist wear and fatigue.

At Topmetalstamping, we utilize advanced tooling and precision stamping machines to meet the automotive industry’s stringent requirements. We offer high-strength materials and ensure that each part is stamped with tight tolerances for seamless assembly. Additionally, we work with materials that offer superior durability and resistance to environmental factors like corrosion, ensuring long-lasting performance in challenging conditions.

2. Aerospace Industry: High Precision and Light Materials for Safety and Reliability

The aerospace industry also demands exceptionally high precision and material performance. Parts in aircraft, whether structural elements or internal components, must be lightweight, strong, and resistant to extreme conditions. A mistake in the manufacturing of an aerospace component can have severe safety implications, making precision and material selection especially critical.

Key Requirements in Aerospace Metal Stamping:

- Precision: Tolerances in aerospace parts are often much stricter than in other industries due to the critical nature of these components. Precision stamping ensures the integrity and safety of the aircraft.

- Material Selection: Lightweight yet strong materials like titanium, high-strength aluminum, and stainless steel are commonly used. These materials must withstand high temperatures, corrosion, and mechanical stress.

- Durability: Parts must be durable enough to withstand the stress of takeoff, flight, and landing. The materials used in aerospace components need to resist fatigue and wear over long periods of time, especially in high-stress areas such as turbine engines.

At Topmetalstamping, we understand the importance of delivering parts that meet aerospace standards. We use precision machinery and carefully selected materials that comply with aerospace specifications, ensuring that every part is manufactured to the highest safety standards.

3. Electronics Industry: Fine Detail and Material Integrity for Complex Components

In the electronics sector, metal stamping plays a significant role in producing small, intricate parts that need to fit together perfectly. Components like connectors, housings, and heat sinks require both fine detail and functional integrity. The precision of these parts is critical for ensuring that electronic devices operate effectively and safely.

Key Requirements in Electronics Metal Stamping:

- Precision: Electronics parts require extremely fine tolerances to ensure that connectors, housings, and other components fit together without issues. These components are often small and intricate, requiring advanced stamping technology to produce with high precision.

- Material Selection: Materials used for electronic parts need to be conductive, durable, and resistant to heat. Copper, brass, and stainless steel are commonly used in the electronics industry for their electrical conductivity and resistance to corrosion.

- Durability: While not exposed to extreme conditions like automotive or aerospace parts, electronic components still need to resist wear, corrosion, and heat. Parts that dissipate heat, such as heat sinks, require materials that can withstand high temperatures without degrading.

At Topmetalstamping, we offer a wide range of materials that meet the specific needs of the electronics industry, including highly conductive materials like copper and specialized alloys. Our precise tooling ensures that we can manufacture even the most complex components with tight tolerances.

4. Medical Industry: Biocompatibility and High Precision for Critical Applications

The medical industry is one of the most demanding sectors in terms of both precision and safety. Parts used in medical devices, such as pump parts, surgical instruments, and diagnostic equipment, must meet strict regulatory standards for biocompatibility and accuracy.

Key Requirements in Medical Metal Stamping:

- Precision: Parts used in medical devices must adhere to very tight tolerances, as even small variations can affect performance and safety.

- Material Selection: Stainless steel is often the material of choice due to its resistance to corrosion and its biocompatibility. Other materials may include titanium or specialized alloys that meet medical-grade standards.

- Durability: Medical parts must be durable, reliable, and able to withstand sterilization processes. They must also be resistant to wear, corrosion, and mechanical fatigue.

At Topmetalstamping, we provide precision stamping solutions for the medical industry. Our materials meet strict biocompatibility standards, and we ensure that all parts undergo rigorous quality control to meet medical certifications. Whether producing surgical tools or components for medical devices, we prioritize precision and safety at every stage of production.

Customer Concerns and Our Solutions

As manufacturers, customers are often concerned with the following issues during the production process:

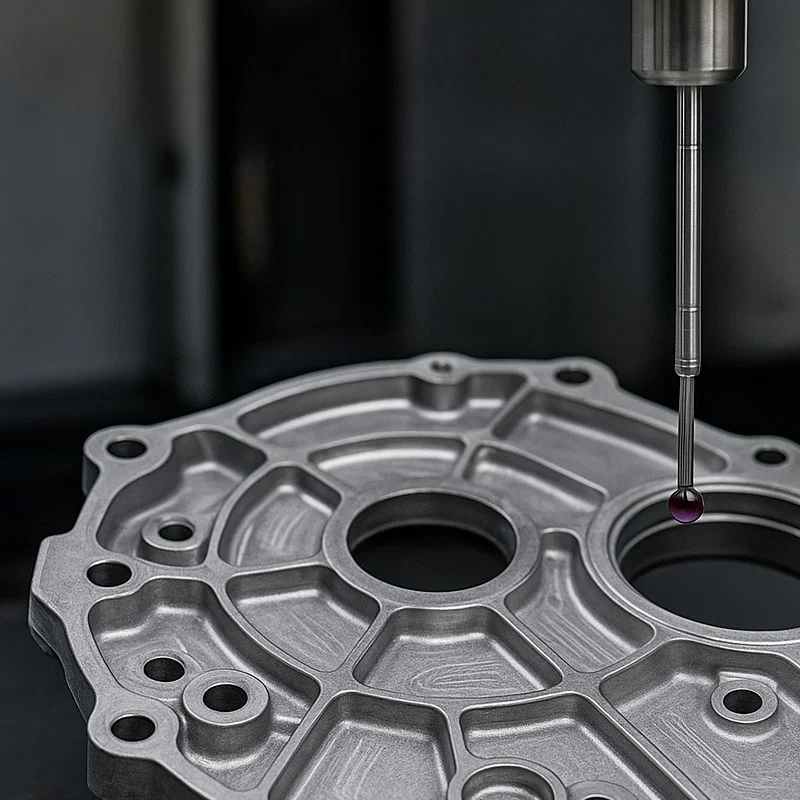

- Precision Tolerances: Tight tolerances are critical across all industries. At Topmetalstamping, we use advanced equipment, including high-precision stamping presses and automated quality control systems, to ensure that every part meets the required specifications.

- Material Quality: Selecting the right material is crucial for ensuring the longevity and performance of metal stamping parts. We offer a wide range of materials that meet industry-specific needs, ensuring that customers receive components that are both durable and functional.

- Durability and Wear Resistance: Many industries require parts that can withstand extreme conditions. We use materials that offer excellent wear resistance and ensure that each part is tested for durability before it reaches the customer.

Partner with Topmetalstamping for Precision and Quality

At Topmetalstamping, we understand that each industry has its own unique requirements when it comes to metal stamping. Whether you need high precision, durable materials, or parts that meet strict regulatory standards, we are here to help. With our advanced tooling and state-of-the-art manufacturing processes, we ensure that every part we produce meets the highest standards of quality.

If you have any specific needs or concerns regarding the precision, material selection, or durability of your stamped parts, don’t hesitate to reach out to our team. Let us work together to create the perfect solutions for your industry. Contact Topmetalstamping today for all your metal stamping needs!