In today’s competitive manufacturing landscape, automation is transforming traditional production methods. Automated assembly lines are now integral to industries seeking efficiency, cost-effectiveness, and scalability. If you’re a manufacturer looking to upgrade your production processes or a business exploring new ways to meet customer demand, understanding the key features of automated assembly lines is crucial.

At Topmetalstamping, we specialize in providing high-precision, custom manufacturing solutions, including advanced assembly line automation. We offer one-stop services that ensure high-quality results, whether you are ramping up production for a complex product or optimizing your assembly processes. Let’s dive into what automated assembly lines are, how they work, and how they can benefit your manufacturing operations.

What is an Automated Assembly Line?

At its core, automated assembly line automation replaces manual labor with machines, robotics, and computer-controlled systems that handle repetitive assembly tasks. These automated systems significantly improve the efficiency, consistency, and speed of production while reducing human error. In contrast to traditional assembly lines, where workers perform specific tasks, automation involves machines performing these operations with minimal human intervention.

On an automated assembly line, products move through a series of workstations, just like in manual assembly lines, but machines perform the required actions at each station. These systems are typically coordinated by a central control unit that synchronizes operations, ensuring smooth transitions between tasks. Sensors and vision systems monitor each station for quality assurance, helping reduce errors and ensuring that every part meets the exact specifications.

The Evolution of Automated Assembly Lines

The automated assembly line has been around for over a century, with significant developments happening over time. The concept was introduced in the early 20th century and has continuously evolved:

- 1901, Ransom E. Olds: The first station-to-station workflow was used at Oldsmobile, leading to a significant increase in production output.

- 1913, Henry Ford: Ford revolutionized manufacturing by introducing the moving conveyor belt at his Highland Park plant, drastically reducing assembly time from 12 hours to just 93 minutes per car.

- 1961, Unimate Industrial Robot: The introduction of industrial robots marked the beginning of robotic automation.

- 1970s, PLCs and Robotics: Programmable Logic Controllers (PLCs) and robotics were integrated into assembly lines, further automating manufacturing processes.

Key Components of an Automated Assembly Line

An automated assembly line consists of various components that work seamlessly to ensure smooth production. These include:

- Conveyor Systems: Conveyor belts or chains transport products through the assembly process. Sensors detect item positions, adjusting speeds and stopping when needed to maintain flow.

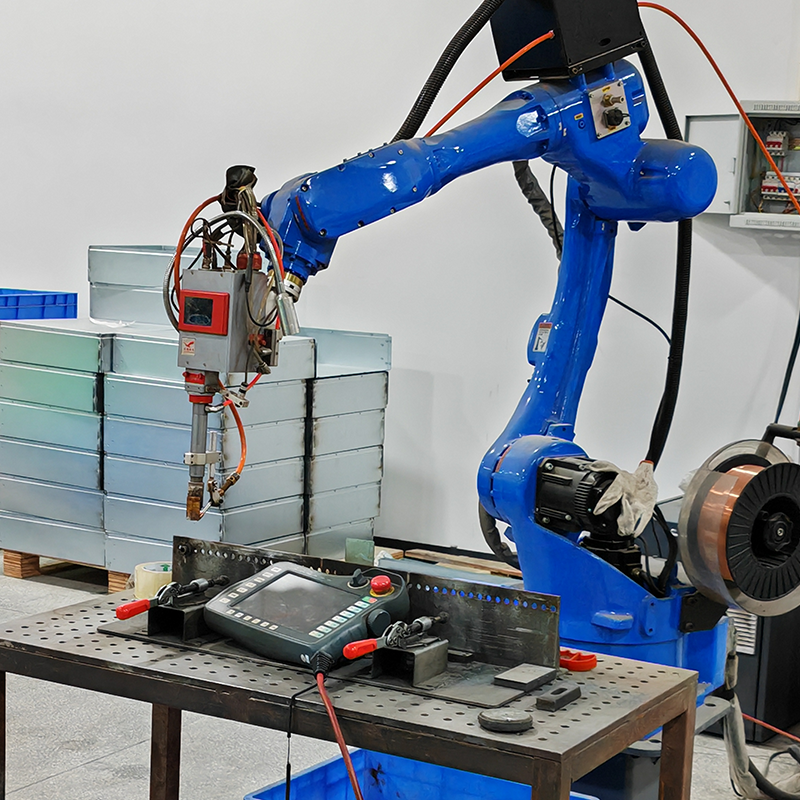

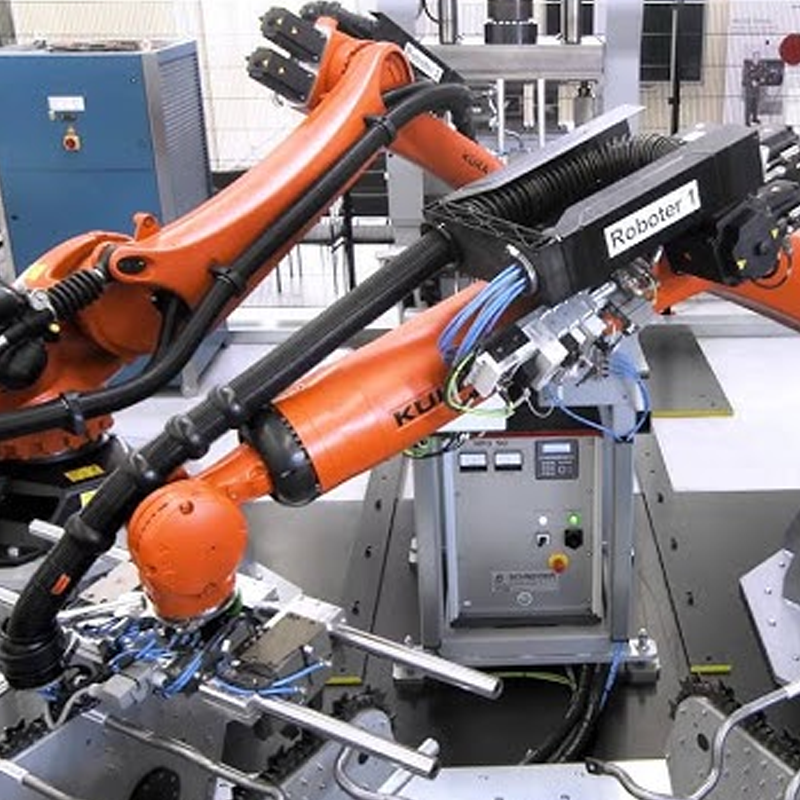

- Industrial Robots: Robots perform tasks like assembly, welding, painting, or packaging. They are programmed to work in sync with other machines on the line, enabling high precision.

- Parts Feeding Systems: These systems automatically orient and present parts to robots or machines for further assembly. Common feeding methods include vibratory bowl feeders, hoppers, and linear feeders.

- Sensors and Vision Systems: These systems provide real-time feedback, ensuring each step of the process is performed correctly. Sensors can detect errors, triggering corrections and halting the line if necessary.

- Control Systems: The control system, usually consisting of PLCs or industrial computers, coordinates the entire operation. It sends commands to machines, monitors real-time data, and ensures production is running smoothly.

- Safety Features: Safety systems, such as fences, sensors, and emergency stop buttons, ensure that operators are protected while interacting with automated machinery.

How Does Assembly Line Automation Work?

The workflow of an automated assembly line is a well-orchestrated sequence of operations. Here’s a look at a typical automated assembly line process:

- Initiation & Feeding: The process starts with parts being correctly oriented and placed onto the line, ensuring the right part is ready for the next operation.

- Precise Transportation: The product is transported via conveyors, with the timing and positioning controlled by the central PLC to ensure synchronization.

- Value-Added Tasks: At each workstation, specific tasks such as assembly, screwing, welding, or painting are performed by robots or other machines.

- Continuous Verification: As products move along the line, sensors provide immediate feedback to verify that each operation has been completed correctly, ensuring quality and consistency.

- Data Communication & Central Coordination: The central control system continuously monitors and communicates with the sensors and machines to adjust operations and troubleshoot issues as they arise.

- Final Handoff: Once the assembly process is complete, the finished product is transferred for packaging or shipping, and the line is reset to handle the next workpiece.

Benefits of Automated Assembly Lines

Automating your assembly line brings numerous advantages that go beyond simple labor replacement. The benefits include:

- Increased Production Efficiency: Machines can work 24/7, operating faster and more consistently than human workers. This leads to higher throughput and quicker turnaround times.

- Improved Quality and Consistency: Automation reduces human error and ensures that every product is made to the same precise specifications, enhancing product quality and consistency.

- Cost Reduction: Although the initial investment in automation can be significant, it ultimately reduces labor costs, increases productivity, and minimizes defects and rework.

- Enhanced Flexibility: With modern automation systems, manufacturers can easily switch between products and adapt to changes in demand or product design without long downtimes.

- Better Workplace Safety: By handling repetitive or dangerous tasks, robots and automation systems improve worker safety, reducing accidents and injuries.

- Scalability: Automated systems allow for easy scaling of production capacity, enabling manufacturers to respond to higher demand without significantly increasing costs.

Challenges in Implementing Automation

While the benefits of automated assembly lines are clear, the transition to automation can be challenging. Some of the hurdles include:

- High Initial Investment: The upfront cost of purchasing robots, machines, and installation can be significant. However, with the right planning, the long-term benefits often outweigh the costs.

- Technical Expertise and Maintenance: Automated systems require specialized skills for setup, maintenance, and troubleshooting. Manufacturers must invest in staff training or hire external experts.

- Integration with Existing Processes: Integrating new automation technology with existing manual processes or infrastructure can be complex, requiring careful planning and implementation.

- Impact on Workforce: Automation may reduce the number of manual jobs needed, necessitating retraining or job reassignment for affected employees.

Types of Automated Assembly Systems

Different types of automated assembly systems are suited for various production needs. These include:

- Fixed Automation: Ideal for high-volume, standardized products. Fixed automation uses specialized equipment that can’t be easily reconfigured, making it cost-effective for mass production.

- Programmable Automation: This system allows for flexibility, as machines and robots can be reprogrammed to assemble different products. It is ideal for medium-volume production.

- Flexible Automation: This type of system adapts quickly to product changes, making it ideal for industries with diverse or rapidly changing product lines.

- Fully Automated Lines: These systems perform nearly all tasks with minimal human intervention and are typically used in high-volume industries like automotive and electronics.

- Semi-Automated Lines: Combining human labor with automation, this system lets workers perform complex tasks while machines handle repetitive or heavy lifting.

Why Choose Topmetalstamping for Your Automation Needs?

At Topmetalstamping, we understand the complexities of transitioning to an automated assembly line. With our OEM services and high-precision custom manufacturing solutions, we help you navigate the challenges and benefits of automation. Our team of experts offers tailored, one-stop service, providing everything from design to implementation.

By choosing Topmetalstamping as your automation partner, you benefit from:

- Custom Service: Tailored solutions designed to meet the unique needs of your production line.

- High Precision: Our components are manufactured to the highest standards, ensuring flawless integration into automated systems.

- Expert Guidance: With years of experience in high-precision manufacturing, we provide expert consultation to help you achieve maximum efficiency.

- Reliable Support: We offer continuous support to ensure your systems run smoothly and efficiently, minimizing downtime.

Conclusion:

Automation is the future of manufacturing, providing unparalleled benefits in terms of speed, quality, and cost-efficiency. If you’re ready to take your production line to the next level, Topmetalstamping is here to provide the expertise and technology you need to succeed. Our custom services and high-precision manufacturing solutions can help you design and implement the perfect automated system for your operations.

Contact us today to discuss how we can optimize your assembly line and help you stay ahead of the competition. Whether you need OEM services or full automation integration, we’ve got you covered. Let’s bring your manufacturing vision to life.