Are rising project costs and elusive tolerances holding you back? At Topmetalstamping, we know that the material you choose for CNC machining isn’t just about final performance—it drives every aspect of your manufacturing process, from tool wear and cycle times to part precision and overall budget. In this blog, we’ll walk you through how material properties affect machining tolerances and costs, explain key considerations for stock selection, and help you match your parts to the right machines. Read on to gain the insights you need to optimize your next project—and when you’re ready, our team at Topmetalstamping is here to help you turn that knowledge into perfectly machined parts.

Understanding CNC Machining Tolerances

What is a tolerance? In CNC machining, tolerance defines the allowable deviation between a part’s actual dimensions and its nominal design dimensions. For most metal parts, a standard tolerance is ±0.005 inches (±0.127 mm), which aligns with ISO 2768-fine guidelines. For plastics or composites, tolerances typically widen to ±0.010 inches (±0.254 mm).

However, many applications demand tighter control: aerospace components, precision medical devices, and high-performance automotive parts often require tolerances as tight as ±0.001 inches (±0.025 mm) or better. Achieving these tight tolerances depends on:

- Machine stability (thermal and structural)

- Tooling quality and wear control

- Material behavior under cutting forces

- Operator skill and inspection protocols

At Topmetalstamping, we routinely hold ±0.001-inch tolerances on aluminum, steel, and specialty alloys by optimizing cutting parameters, using ultrasharp tooling, and calibrating our machines for thermal compensation.

How Material Properties Influence Machining Precision and Cost

-

Hardness and Tool Wear

Harder materials—such as hardened steels, titanium, and certain stainless alloys—accelerate tool wear. As cutting edges dull, surface finish degrades, tolerances shift, and cycle times increase due to slower feeds and lower speeds.

Softer metals, like 6061 aluminum or mild steel, are easier on tools but can “gum up” if speeds and feeds aren’t dialed in, leading to built-up edge (BUE) and poor finishes.

Cost Impact: Frequent tool changes, higher-cost inserts (e.g., PVD-coated or carbide), and slower cycle times all drive up per-part costs. When machining harder alloys, factor in at least a 20–50% increase in tooling expenses and up to 30% longer cycle times compared to aluminum.

-

Thermal Conductivity and Stability

Materials with high thermal conductivity (e.g., aluminum, copper alloys) dissipate heat quickly, reducing heat-affected zones (HAZ) and helping maintain tight tolerances.

Low-conductivity materials (e.g., stainless steel, plastics) retain heat at the cut edge, causing localized expansion and contraction that can lead to dimensional drift or residual stresses.

Cost Impact: Poor thermal management may necessitate additional cooling, slower machining, or stress-relief operations. These add time and cost, and potentially require secondary operations like heat treatment or stabilization.

-

Ductility and Work Hardening

Work hardening occurs when materials like stainless steels or certain nickel alloys become harder at the cut surface due to plastic deformation. This can make subsequent passes more difficult, increasing load on tools and requiring multiple light finishing passes.

Ductile plastics can smear rather than chip, leading to stringy swarf and potential surface defects if chip evacuation isn’t managed.

Cost Impact: Work-hardened surfaces often require extra finishing passes or specialized tooling, raising cycle time. In plastics, poor chip control can damage parts or tooling, leading to scrapped parts and rework.

-

Surface Finish and Microstructure Changes

Machining-induced stresses and microstructural changes (e.g., recast layers or white layers in metal) can affect wear resistance and fatigue life.

Polymers can deform under the pressure of tooling, requiring slower, more controlled cuts.

Cost Impact: Ensuring a high-quality surface finish or preventing microstructural damage can require secondary processes—grinding, polishing, or even chemical etching—each adding cost and lead time.

Selecting the Right Stock Material

Choosing the appropriate stock for your project goes beyond matching the final functional requirements. Here are key factors to weigh:

| Factor | Consideration | Impact on Machining & Cost |

| Machinability | Hardness, tensile strength, thermal conductivity, work-hardening | Drives tooling life, feeds/speeds, surface finish quality |

| Mechanical Properties | Strength, toughness, corrosion resistance, weight | Determines suitability for application, may raise material cost |

| Raw Material Cost | Price per pound or sheet, availability, lead times | Exotic or high-demand alloys can add 30–200% to material costs |

| Thermal Stability | Dimensional stability under heat | Affects achievable tolerances and risk of warping |

| End-Use Environment | Exposure to chemicals, UV, high/low temperatures | May require specialty alloys or coatings, increasing costs |

| Part Complexity | Geometry, undercuts, deep pockets | Guides need for 3-axis vs. 5-axis machines; affects setup time |

Example:

6061 Aluminum is popular for its excellent machinability, high thermal conductivity, moderate strength, and low cost. It’s ideal for tight-tolerance housings, fixtures, and structural components.

17-4 PH Stainless Steel offers high strength and corrosion resistance but work-hardens rapidly and requires slower feeds, premium tooling, and potentially post-machining heat treatment—resulting in 2–3× higher cost compared to aluminum.

At Topmetalstamping, we stock over 100 metals and plastics, from common steels to aerospace-grade superalloys and engineering polymers. We’ll guide you through material tradeoffs so you can hit your budget and performance targets.

How Machining Alters Material Properties

Even before a part leaves the shop floor, CNC machining can change its properties:

-

Work Hardening

Surface layers become harder due to plastic deformation.

Can benefit wear resistance but complicate subsequent cuts.

-

Residual Stresses

Cutting forces and thermal gradients introduce stresses that may cause warping or dimensional shifts over time.

Stress-relief annealing or optimized roughing/finishing strategies can mitigate these effects.

-

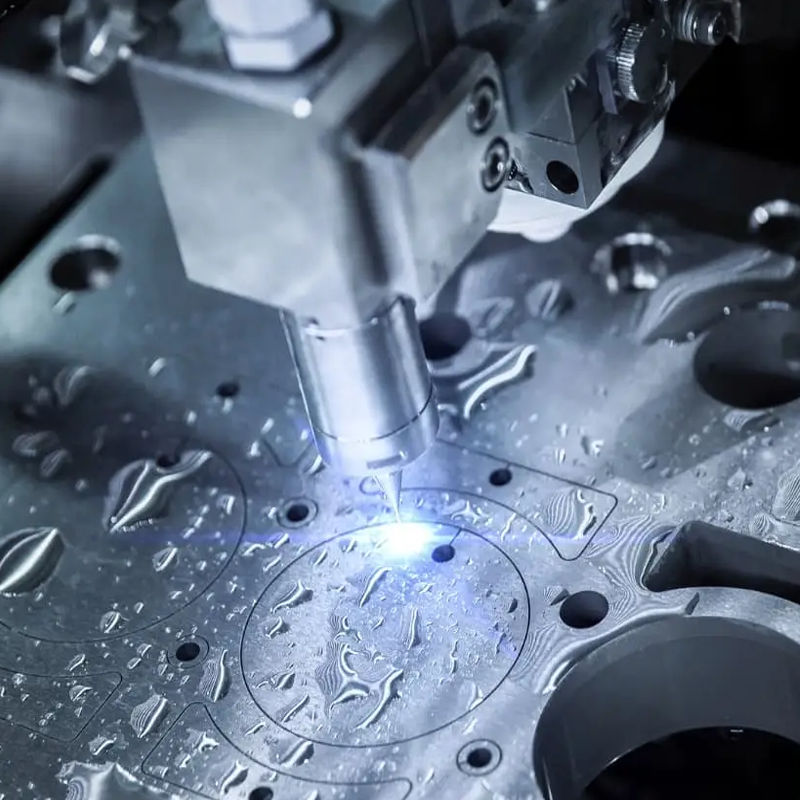

Heat-Affected Zone (HAZ)

High cutting temperatures can alter microstructure near the cut surface, particularly in steels and nickel-based alloys.

May require light grinding or shot-peening to restore surface integrity.

By understanding these effects, our engineers at Topmetalstamping choose optimal cutting parameters, coolant strategies, and tool paths to minimize unwanted alterations, ensuring your part performs exactly as intended.

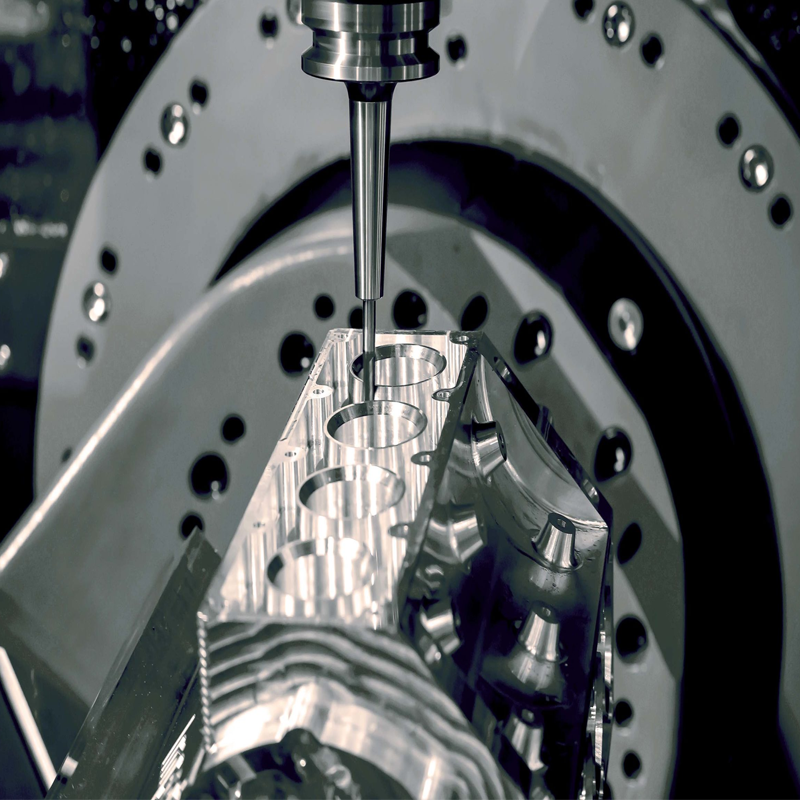

Choosing the Right CNC Machine

A perfectly selected material still needs the right machine to achieve your tolerance and cost goals. Key considerations include:

Axis Configuration

3-Axis Mills handle prismatic parts with simple geometries.

4-Axis/Rotary adds indexing for cylinder features.

5-Axis Mills accommodate complex undercuts and multi-face machining without multiple setups.

Machine Capacity

Part size limits (e.g., 80″ x 40″ tables vs. compact benchtop machines).

Spindle power and torque (critical for hard alloys and heavy cut depths).

Control Precision

High-end controls with thermal compensation and backlash reduction deliver repeatable ±0.0005″ tolerances.

Automation and Volume

For high-volume production, machines with pallet changers or robotic load/unload can cut labor costs and improve uptime.

Budget Constraints

Matching job complexity to machine capabilities avoids over‐engineering—and overspending—on unnecessary features.

At Topmetalstamping, our shop floor features a mix of compact 3-axis mills, 5-axis horizontals, and turnkey cells for automated production. We’ll recommend the optimal machine to balance your part’s complexity, material, tolerance, and volume requirements.

Putting It All Together

By carefully evaluating material properties, machining effects, stock selection factors, and machine capabilities, you can:

Avoid unexpected tool wear and downtime by choosing materials that match your tooling strategy.

Achieve consistent tight tolerances with the right combination of material, machine, and machining parameters.

Control costs by balancing raw material price against machining difficulty and cycle times.

Minimize post-machining processes through proactive selection of alloys and finishing strategies.

Ready to Optimize Your CNC Machining Process?

At Topmetalstamping, we’re passionate about helping you get the most out of every project. From prototype runs to high-volume production, our expertise in materials, machining strategies, and precision equipment ensures you hit your quality targets and cost goals.

Contact us today to discuss your next CNC machining project. Let us help you select the right material, define realistic tolerances, and choose the best machine setup—so your parts come off the line on spec, on time, and within budget.