Overview

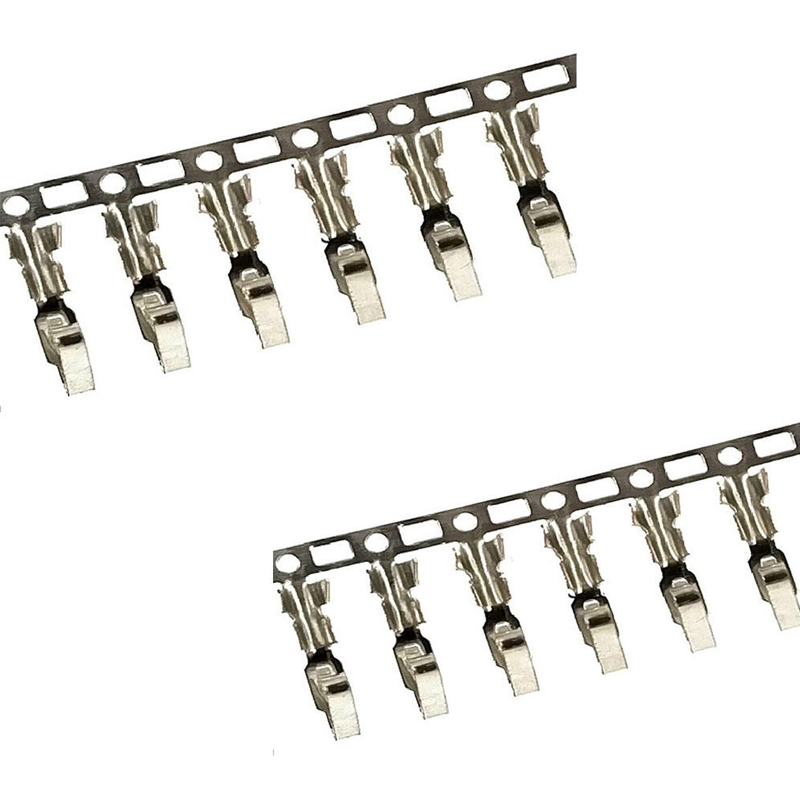

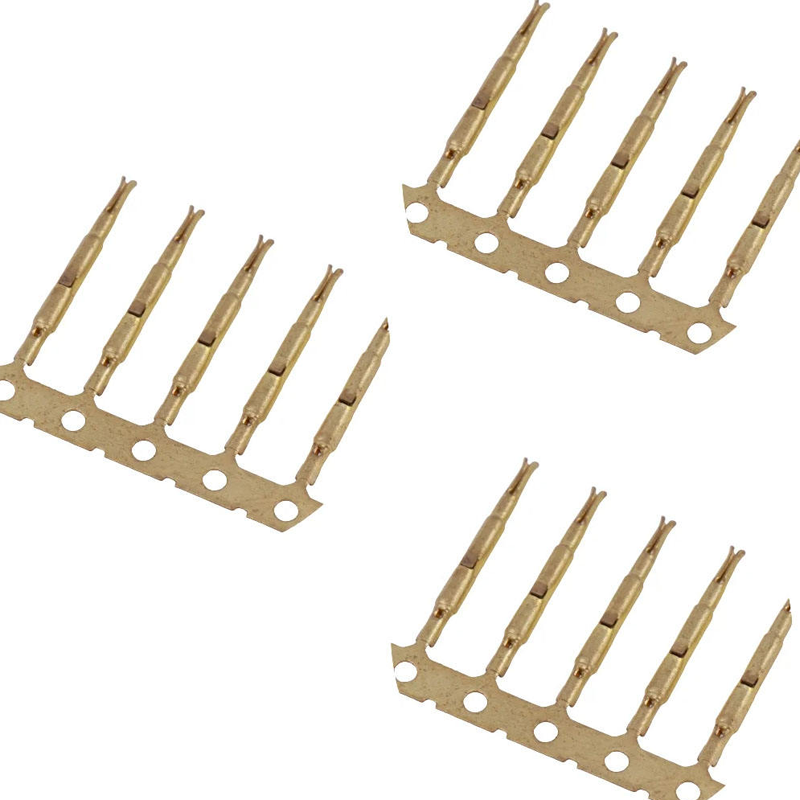

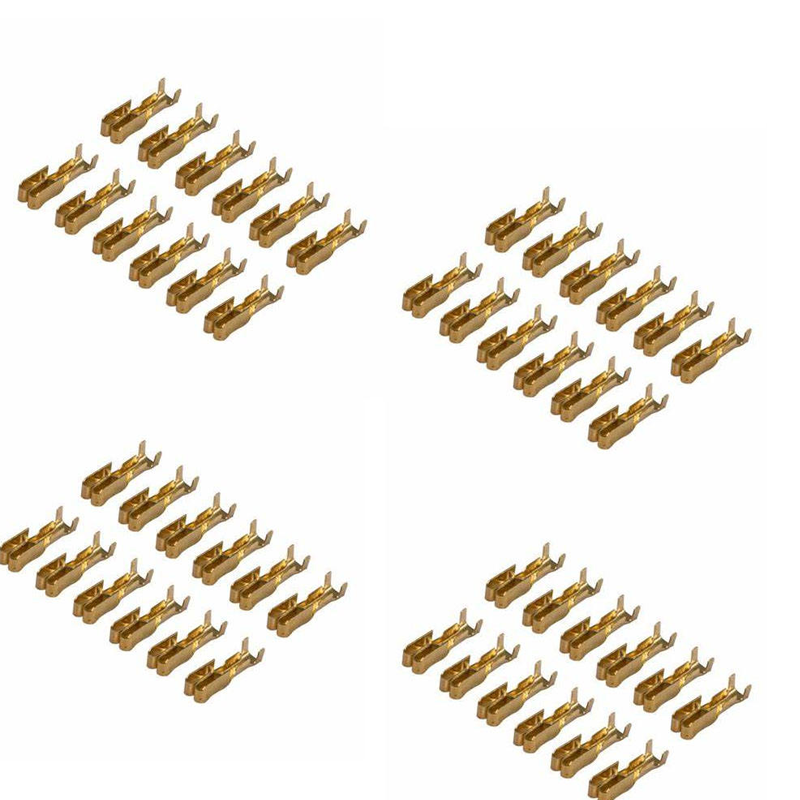

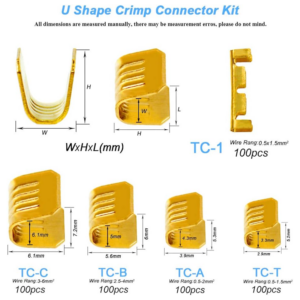

We specialize in manufacturing high-precision Custom Sheet Metal Fabrication Crimp Female Terminal Connectors, engineered for reliable signal and power transmission in electronic PCB applications. Produced from premium copper alloys and selectively plated for optimal performance, our terminals ensure excellent conductivity, secure crimp retention, and long-term durability. Utilizing advanced progressive die stamping with tooling crafted via CNC machining and EDM processes, we achieve consistent dimensional accuracy and superior finish. As a trusted OEM partner, we provide complete solutions from prototyping to high-volume production, backed by rigorous electrical and mechanical validation to meet the exacting demands of consumer electronics, automotive ECUs, and industrial control systems.

Features

| Feature | Specification |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Base Material | C11000 Copper, C5191 Phosphor Bronze, C26000 Brass |

| Customization | Fully customizable design, plating, and packaging |

| Sample | Available for evaluation and testing |

| Specification | Custom to drawing; standard fits for 0.8mm, 1.0mm, 1.5mm male pins |

| Packaging | Reel & tape (ammo pack), bulk pack, or custom ESD-safe packaging |

| Insulation/Color | Optional PVC/Nylon sleeve; plating determines final color (tin-silver, gold, etc.) |

Surface Finishing Options

-

Selective Tin Plating: Provides excellent solderability, good corrosion resistance, and a cost-effective surface for general-purpose applications.

-

Selective Gold Plating (Flash or Hard Gold): Ensures superior corrosion resistance, low contact resistance, and stable performance for high-reliability and low-voltage signal contacts.

-

Nickel Underplate + Gold Flash: Offers enhanced wear resistance and barrier protection against substrate diffusion, ideal for high-cycle mating applications.

-

Silver Plating: Delivers the highest electrical and thermal conductivity, suitable for high-current power terminal applications.

-

Anti-Corrosion Passivation: An additional chemical treatment to protect bare copper areas and enhance shelf life.

Quality Assurance

Our quality assurance for custom crimp female terminals is governed by a stringent, process-controlled system compliant with ISO 9001 and IATF 16949 standards. We begin with certified copper alloy strips verified for composition and temper. The progressive stamping dies, manufactured using high-precision CNC machining and Wire EDM, are rigorously inspected with CMMs to guarantee form accuracy. In-process Statistical Process Control (SPC) monitors critical dimensions of the crimp barrel, contact spring geometry, and carrier alignment. Finished terminals undergo definitive testing: contact resistance is measured via four-point probe, plating thickness and composition are verified with XRF, mechanical integrity is assessed through tensile pull-force tests on crimped wires, and solderability is validated per industry standards. All production lots are fully traceable from raw material to final shipment.

Our Factory

Our integrated manufacturing facility is equipped for end-to-end terminal production. The core of our capability lies in our advanced tool & die workshop, where CNC machining centers and precision Wire EDM machines fabricate complex, multi-stage progressive dies with micron-level accuracy. Our stamping floor houses high-speed precision presses fitted with these dies, capable of running continuous copper alloy strips to produce terminals with exceptional consistency. In-house plating lines perform selective or barrel plating under automated control. We complement this with automated optical inspection (AOI) systems for dimensional and surface defect detection, and fully equipped labs for electrical, mechanical, and environmental testing. This vertically integrated, certified operation ensures we deliver reliable, high-performance terminals that meet exact specifications for the most demanding PCB applications.

Reviews

There are no reviews yet.