Description

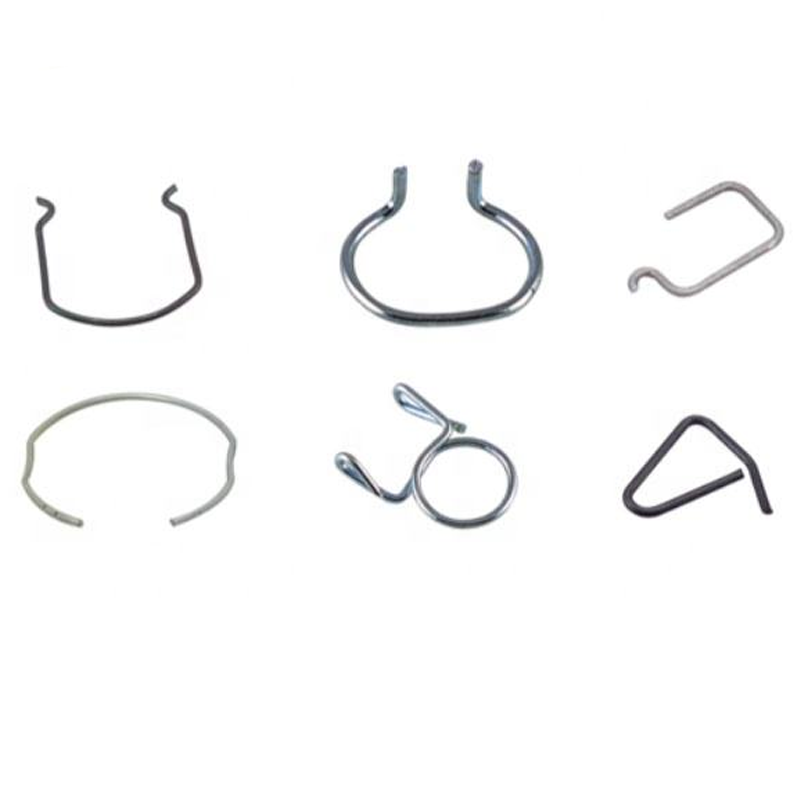

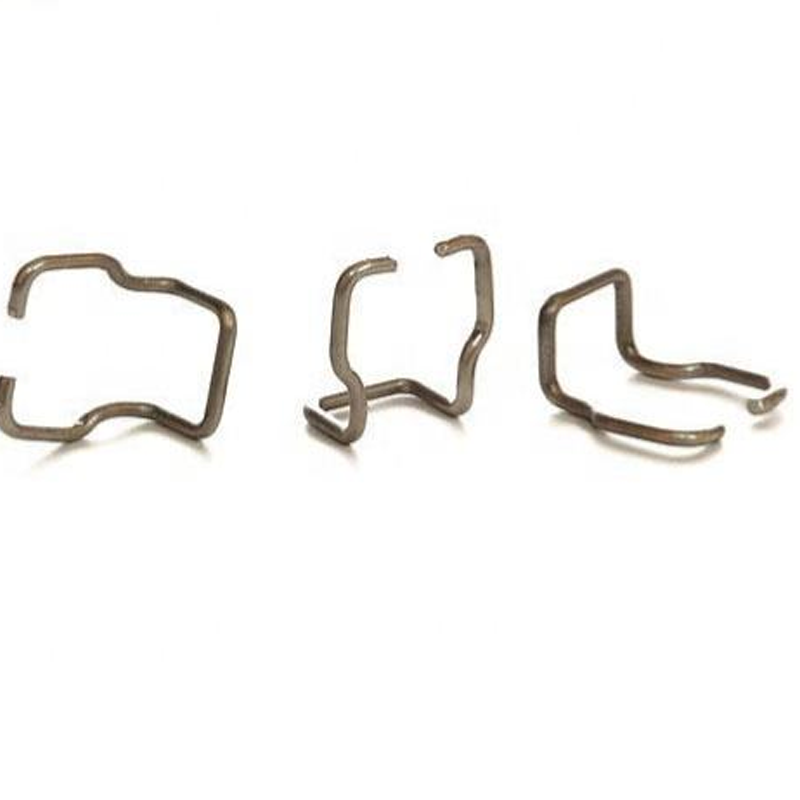

Our Custom U-Shaped Wire Forming Spring Clips are engineered for reliable retention, resilient spring force, and long-term dimensional stability in demanding industrial, automotive, and electronics assemblies. Manufactured from premium spring steels and copper alloys using CNC wire forming, progressive stamping, precision bending, and controlled heat-treat processes, our clips deliver repeatable spring rates, tight tolerances, and superior fatigue life. Typical applications include cable management, hose clamps, battery retainers, EMI grounding clips, and precision fastening in machinery and vehicle systems. We offer end-to-end OEM services from rapid prototyping and toolmaking to high-volume production and aftermarket supply.

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM / Custom |

| Product Type | U-shaped spring clips, wire forms, retaining springs |

| Material Options | Music wire (UNS A228), Stainless steel (302/304/316/301), Phosphor bronze, Beryllium copper, Spring steel (65Mn) |

| Wire Diameter Range | 0.20 mm – 6.0 mm (custom sizes available) |

| Tolerance | Typical ±0.02–±0.05 mm (application dependent) |

| Hardness / Strength | Heat-treated to required HRC or tensile strength per spec |

| Surface Finish | Zinc / Nickel / Tin plating, Passivation, Black oxide, Anodized (for aluminum inserts) |

| MOQ | Small orders / prototypes accepted |

| Certifications | ISO 9001, IATF 16949 (optional) |

| Lead Time | Prototypes: 7–14 days; Production: 15–30 days (depends on tooling) |

| Packaging | Bulk, taped reels, trays, or custom packaging |

Key Advantages

- High fatigue resistance and consistent spring force over lifecycle.

- Tight dimensional control for precision mating and repeatable assembly.

- Wide material choice for conductivity, corrosion resistance, and mechanical strength.

- Flexible production scale — from rapid prototypes to high-volume automated runs.

Typical Production & Process Capabilities

- Material Procurement & Prep — Certified spring wires and strip stocked to customer spec; pre-cleaning and spool handling to avoid contamination.

- CNC Wire Forming & Progressive Stamping — Multi-axis CNC formers and high-speed progressive dies produce complex U-shapes, hooks, and formed features with consistent geometry.

- Secondary Operations — Laser trimming, coining, bending, flaring, swaging, and insert overmolding where required.

- Heat Treatment & Stress Relief — Controlled hardening, tempering, and stress-relief cycles to set spring properties and minimize relaxation.

- Surface Treatments — Electroplating (zinc, tin, nickel), passivation for stainless steels, black oxide, or custom coatings for wear and corrosion resistance.

- Finishing & Assembly — Deburring, tumble/shot peening for fatigue life, ultrasonic cleaning, and automated assembly into subcomponents.

- Testing & Inspection — Spring rate testing, tensile/yield verification, dimensional inspection (CMM/optical), salt spray corrosion tests, and lifecycle fatigue testing.

Surface Treatment & Coating Options

- Zinc / Clear Chromate — Cost-effective corrosion protection.

- Nickel Plating — Durable, wear-resistant conductive finish.

- Tin Plating — Excellent solderability for electrical contacts.

- Passivation (Nitric/Citric) — Improves stainless steel corrosion resistance.

- Black Oxide — Minimal dimensional change with cosmetic finish.

- Custom Specialty Coatings — PTFE, DLC, or epoxy for specific friction or chemical resistance requirements.

Quality Assurance

We implement a full quality program: incoming material certification, first-article inspection (FAI), in-process SPC monitoring, and 100% final inspection where required. Equipment includes CMM, optical comparators, force gauges for spring testing, salt spray chambers, and automated vision systems. Full lot traceability and PPAP documentation available for automotive customers.

Why Partner With Us?

- Engineering Support — Design for manufacturability (DFM), spring-rate optimization, and CL (cost-loading) guidance.

- Tooling & Prototyping — In-house progressive die design, rapid prototyping, and low-volume pilot runs shorten time-to-market.

- Scalable Manufacturing — Automated CNC forming and high-speed stamping lines for volume efficiency and consistent quality.

- Compliance & Reliability — ISO-backed processes and rigorous testing ensure parts meet automotive and industrial specifications.

Our Facility

Our plant operates multiple CNC wire forming cells, 30+ progressive stamping presses (25–300 tons), precision wire EDM, heat treatment furnaces, and plating lines. Automated assembly, ultrasonic cleaning, and visual inspection stations support end-to-end production for complex spring clip assemblies.For engineering drawings, spring rate simulations, or a quote for Custom U-Shaped Wire Forming Spring Clips, contact our technical sales team with your CAD file or sample — we’ll provide rapid prototyping and a detailed production proposal.

Reviews

There are no reviews yet.