Overview:

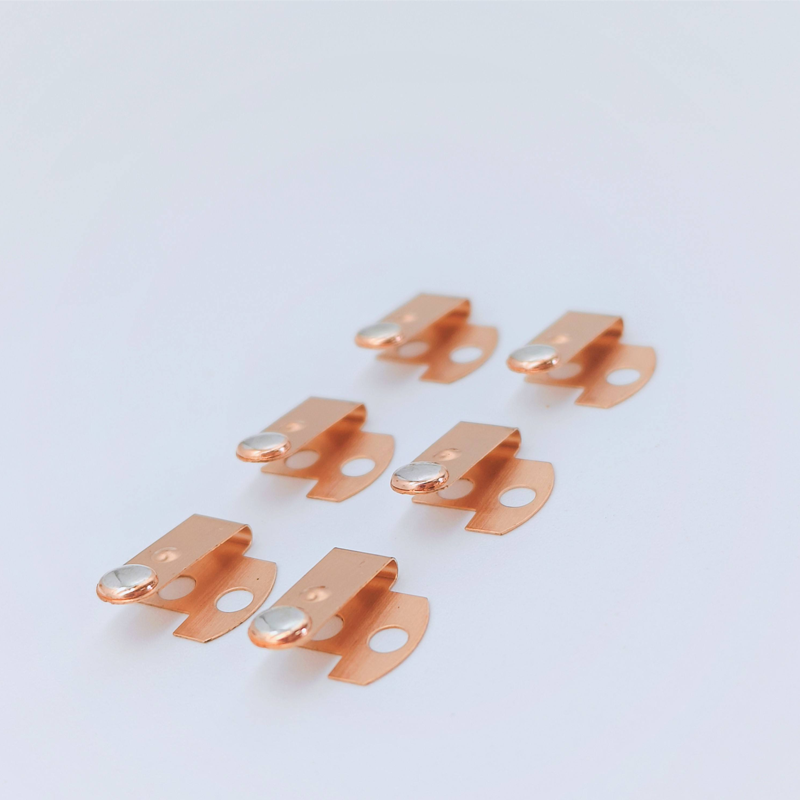

Our Customized Progressive Die Stamping Silver Plating Brass Electronic Contacts for the Telecommunications Industry are high-precision components engineered to meet the demanding performance requirements of telecommunications systems. Manufactured using high-quality brass and silver plating, these electronic contacts are produced through advanced progressive die stamping processes, ensuring exceptional reliability, conductivity, and durability. As an experienced manufacturer, we provide tailored OEM solutions to meet your exact specifications, offering full support from design to production. Our precise manufacturing methods and stringent quality control ensure that each component optimizes electrical performance and meets the standards required for telecommunications applications.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Brass with Silver Plating |

| Dimension | As per drawing or custom’s sample |

| Sample | Available |

| Certification | IATF 16949:2016, ISO 9001:2015, RoHS |

| OEM | Yes |

| Inspection | 100% factory inspection in-house |

| MOQ | According to your requirement |

| Tolerance | ±0.01 mm or custom |

| After-Sale Service | Yes |

| Process | Progressive Die Stamping |

| Surface Treatment | Silver Plating |

Surface Treatment Options:

- Silver Plating: Applied to enhance electrical conductivity, corrosion resistance, and aesthetic appeal, making the components ideal for high-performance telecommunications and electronics systems.

- Anodizing (Optional): Improves surface hardness and corrosion resistance, ideal for products exposed to harsh environments.

- Electropolishing: Provides a smooth, high-gloss finish to reduce friction and enhance the longevity of the electronic contacts.

Quality Assurance:

Our quality assurance process for Customized Progressive Die Stamping Silver Plating Brass Electronic Contacts ensures that every component meets the highest industry standards. Certified under ISO 9001:2015 and IATF 16949:2016, we implement rigorous testing protocols to guarantee the reliability and performance of our components. We utilize coordinate measuring machines (CMM), hardness testers, surface roughness analyzers, and electrical conductivity testers to ensure precise dimensions, material integrity, and optimal performance. All products undergo 100% in-house inspections to ensure the components meet exacting standards for telecommunications applications.

Factory Show:

Our state-of-the-art manufacturing facility is equipped with advanced stamping machines and CNC machines, ensuring the precision and consistency required for high-performance progressive die stamping. We operate 25 punch presses, ranging from 25 to 300 tons, capable of producing complex geometries with tight tolerances. In addition to progressive die stamping, we utilize advanced electroplating techniques to achieve uniform and high-quality silver plating that enhances the durability and conductivity of our electronic contacts. Our production process is fully automated with integrated systems such as high-speed die-cutting, automated vision systems, and ultrasonic cleaning, ensuring precision and operational efficiency.

Our commitment to excellence is reflected in our ISO 9001 and IATF 16949 certifications, ensuring that our silver-plated brass electronic contacts meet the highest standards of quality, reliability, and performance, making them the ideal choice for the telecommunications industry.

Reviews

There are no reviews yet.