Overview

Our Metal-Stamped Copper Alloy Contact Busbars are engineered for high-performance electrical interconnects used in automotive, EV battery systems, power distribution modules, inverters, charging stations, and telecom power racks. Produced with precision progressive stamping and secondary forming, then finished with high-quality silver plating, these busbars deliver excellent electrical conductivity, low contact resistance, and robust mechanical reliability under vibration and thermal cycling. Designed and manufactured under IATF 16949 processes, we provide full OEM services including tooling, prototype validation, selective plating, assembly, and just-in-time production to support automotive and industrial programs.

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM / White Label |

| Material | ETP / Electrolytic Copper (C101/C1100), Phosphor Bronze, Beryllium Copper (for spring/contact applications) — alloy selection by electrical/mechanical requirement |

| Process | Progressive stamping, blanking, coining, CNC bending/forming, annealing, trimming, piercing, secondary machining, laser/ultrasonic welding |

| Thickness Range | 0.2 mm – 12.0 mm (dependent on alloy and stamping die capacity) |

| Dimensions | Custom per 2D drawing or 3D CAD model |

| Tolerance | Standard ±0.02 mm; precision areas to ±0.01 mm upon request |

| Surface Finish | Bright silver plating, selective silver plating, tin, nickel, or passivation |

| Plating Thickness | Typical silver plating 0.1–5 µm (adjustable per spec) |

| Electrical Performance | Engineered for low contact resistance and high current carrying capability (design dependent) |

| Certification | IATF 16949:2016, ISO 9001:2015, RoHS, REACH |

| MOQ | Flexible — based on part complexity and tooling |

| Sample | Available for evaluation |

| Lead Time | Tooling & prototype: 2–6 weeks; production: per order schedule |

Surface Treatment & Finishing Options

- Silver Plating (Selective or Full) — low contact resistance, excellent conductivity and solderability; ideal for high-current and switch/contact surfaces.

- Tin Plating — excellent solderability and cost-effective corrosion protection.

- Nickel Underplate — diffusion barrier and enhanced wear resistance beneath top coats.

- Passivation / Chromate Conversion — for corrosion protection on mixed-metal assemblies.

- Mechanical Finishes — tumble/polish, sandblasting, deburring, and edge-rounding for safe handling and assembly.

- Custom Coatings — enamel insulations, heat-resistant coatings, or lacquer per spec.

Key Benefits

- High Conductivity & Low Losses: ETP copper options maximize conductivity and minimize voltage drop across busbar networks.

- Design Flexibility: Complex geometries, multi-bend forms, integrated tabs, and assembly features achievable via progressive dies and CNC forming.

- Automotive-Grade Reliability: Produced under IATF 16949 systems with process traceability, suitable for EV and safety-critical applications.

- Selective Plating Options: Silver on contact faces with cost-effective tin or nickel on non-contact areas to optimize performance vs. cost.

- Robust Mechanical Performance: Controlled annealing and heat-treat cycles deliver predictable springback, fatigue resistance, and dimensional stability under thermal cycling.

Quality Assurance

All production follows automotive quality protocols and full material traceability. Our QA program includes:

- Incoming material verification (certs & chemical/mechanical testing).

- Dimensional inspection by CMM, optical comparators, and automated vision systems.

- Electrical testing using micro-ohmmeters and contact resistance mapping.

- Plating verification via XRF for thickness and uniformity.

- Environmental testing (salt spray, humidity, and thermal cycling) and mechanical endurance/fatigue tests where required.

- Process controls include SPC, first article inspection (FAI), PPAP documentation, and batch traceability to support automotive suppliers.

Why Partner With Us?

- Automotive-grade expertise with IATF 16949 systems and OEM supply experience.

- Full turnkey service from tooling → stamping → plating → assembly → validated delivery.

- Cost and performance optimization through selective plating and alloy selection tailored to your electrical/mechanical needs.

- Flexible production scale — from prototype samples to high-volume, sequenced deliveries for vehicle programs.

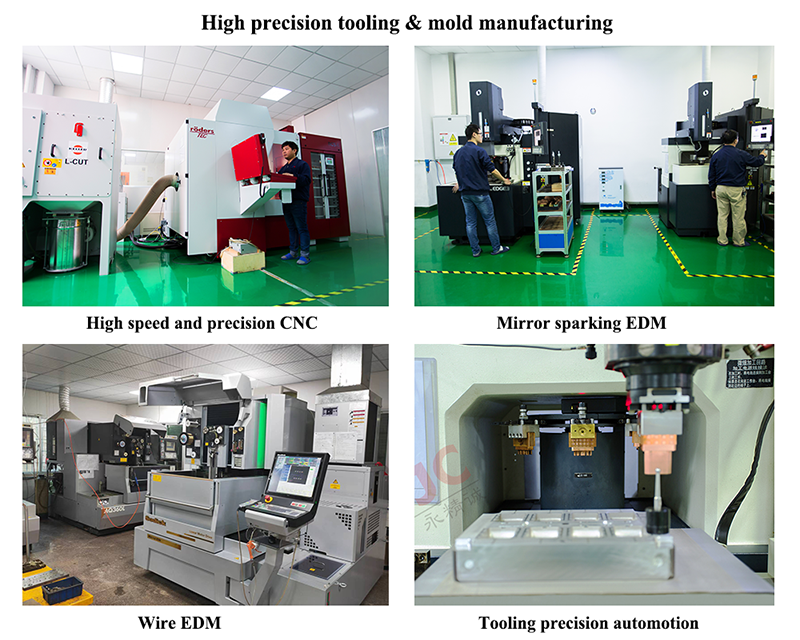

Factory Capabilities & Services

Our facility delivers end-to-end metal stamping production: we design and build progressive dies in-house using CNC machining, wire EDM, and precision grinding for rapid prototyping and rugged tooling; run high-volume production on multi-station progressive and heavy blanking presses; perform precision secondary operations such as CNC bending, IR annealing, press-fit features, laser and ultrasonic welding, and automated assembly; finish parts on automated selective and full-coverage electroplating lines (silver, tin, nickel) with controlled chemistries and post-plating passivation; and verify and pack products using automated test rigs, protective kitting, and ESD/clean packaging for sensitive assemblies. Throughout the program we provide engineering support—DFM reviews, thermal/current modeling, prototype evaluation, and APQP/PPAP—to ensure reliable, scalable long-term supply.

Reviews

There are no reviews yet.