Overview:

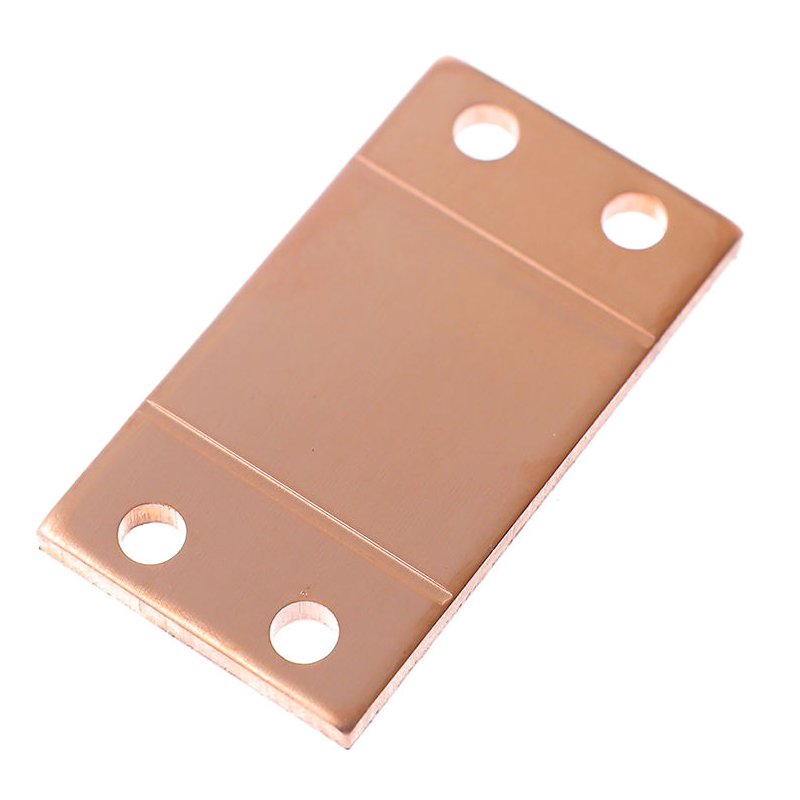

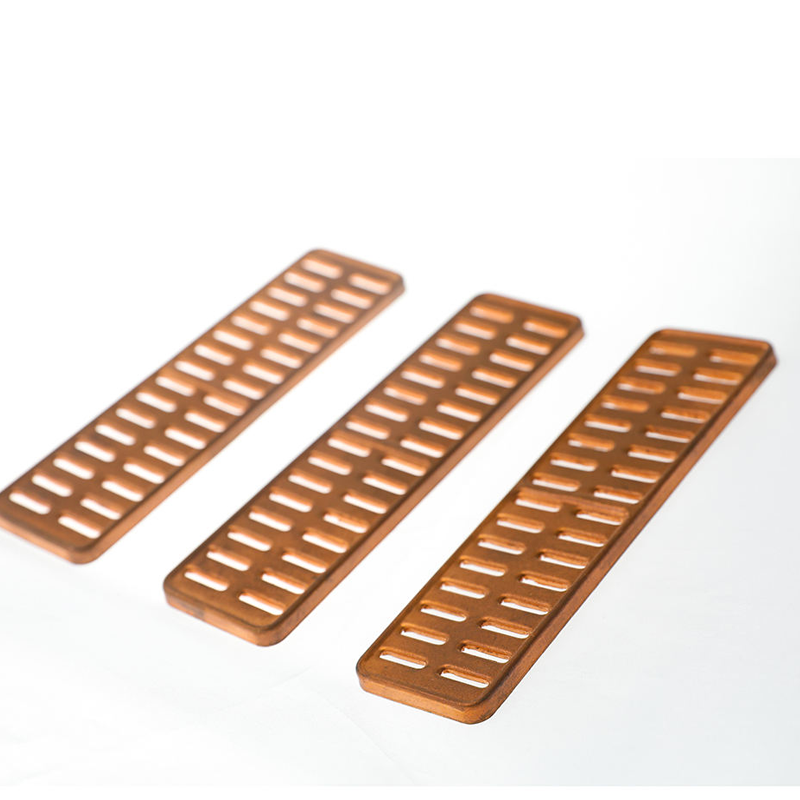

Our OEM Precision Copper Sheet Metal Heat Sink with Advanced Laser Cutting is meticulously engineered to provide optimal thermal management for high-performance electronic devices, ensuring superior cooling efficiency. Designed specifically for applications in communication equipment, this heat sink is fabricated from high-quality copper using precision laser cutting technology to achieve tight tolerances and excellent heat dissipation. By employing advanced manufacturing processes and the latest in thermal technology, we offer custom-tailored heat sinks that meet your exact specifications. With our commitment to quality and reliability, our products enhance the longevity and performance of communication systems while providing unparalleled cooling solutions.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Copper |

| Dimension | Custom (based on drawing or sample) |

| Sample | Available |

| Certification | IATF 16949:2016, ISO 9001:2015, RoHS |

| OEM Services | Available |

| Inspection | 100% in-house factory inspection |

| MOQ | Custom requirements accepted |

| Tolerance | ±0.01mm (customizable) |

| After-Sale Service | Yes |

| Manufacturing Processes | Laser Cutting, Bending, Stamping |

Surface Treatment Options:

- Anodizing: Enhances the durability and corrosion resistance of the heat sink, creating a protective oxide layer that is ideal for components exposed to harsh environmental conditions.

- Powder Coating: Offers a durable, high-quality finish that resists chipping, fading, and scratching. This surface treatment provides long-lasting protection for metal surfaces in demanding applications.

- Electroplating: A thin layer of metal is deposited onto the copper surface to improve corrosion resistance, wear resistance, and aesthetic appeal. This treatment is often used to enhance conductivity and achieve decorative finishes.

- Electropolishing: This process smooths and polishes the copper surface to a high-gloss finish, improving corrosion resistance and reducing friction, ideal for precision and high-performance applications.

Quality Assurance:

Our OEM Precision Copper Sheet Metal Heat Sinks are manufactured under strict quality control protocols to ensure the highest level of precision and performance. We are certified to both ISO 9001:2015 and IATF 16949:2016 standards, reflecting our commitment to quality in every aspect of production. Each heat sink undergoes rigorous testing, including coordinate measuring machine (CMM) evaluations, hardness testing, and surface roughness analysis to confirm precise dimensions, material integrity, and optimal heat dissipation performance. Our certified quality control team conducts 100% in-house inspections to guarantee the highest quality for all communication equipment applications.

Why Choose Our Precision Copper Heat Sinks?

- Advanced Laser Cutting Technology: Utilizes the latest laser cutting techniques for precise, consistent dimensions and excellent surface finish, essential for high-performance cooling applications.

- Superior Thermal Performance: Copper’s excellent thermal conductivity ensures that heat is dissipated efficiently, preventing overheating in critical electronic components.

- Custom Solutions: Tailored to your exact specifications, from design to final production, ensuring that the heat sinks meet your specific needs for communication equipment.

- High-Quality Materials and Surface Treatments: Premium copper material combined with various surface treatments for improved durability, corrosion resistance, and enhanced heat dissipation.

- Rigorous Quality Control: Every heat sink undergoes a multi-step inspection process, ensuring that each product performs to the highest standards in real-world applications.

With our OEM Precision Copper Sheet Metal Heat Sink, your communication equipment will benefit from superior cooling, enhanced performance, and extended service life, making it an essential solution for high-demand environments.

Factory Show:

Our advanced manufacturing facility is equipped with cutting-edge technologies, including 25 punch presses ranging from 25 to 300 tons, high-precision wire EDM systems, advanced grinding and polishing stations, and ultrasonic cleaning technologies. These resources enable us to manufacture copper heat sinks with exceptional accuracy and superior surface finishes. Our metal plating services include electroplating, zinc plating, nickel plating, chrome plating, and anodizing, ensuring each product achieves uniform finishes that enhance durability and thermal performance.

Our automated production processes, stringent quality control systems, and high-quality raw materials ensure that every product meets rigorous industry standards. Fully certified to ISO 9001 and IATF 16949, we consistently deliver precision-engineered heat sinks that provide optimal performance and thermal efficiency for communication equipment.

Reviews

There are no reviews yet.