Overview:

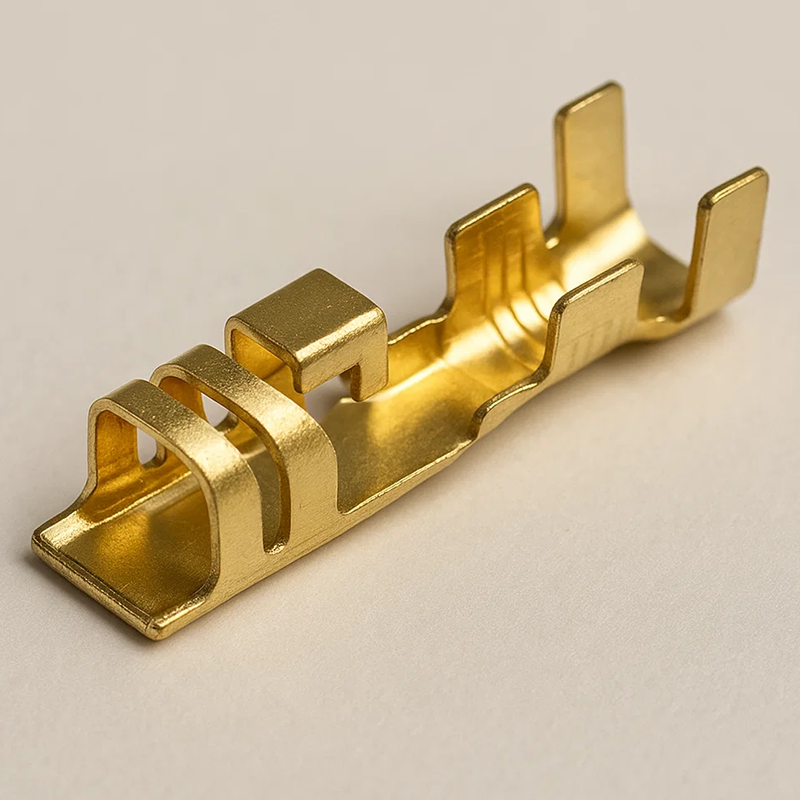

Our OEM Precision Gold-Plated Stamped Antifatigue Connectors for Electric Vehicles are expertly engineered electrical components designed to deliver low contact resistance, exceptional corrosion protection, and superior mechanical endurance. Constructed from high-conductivity copper or brass alloys through advanced progressive-die stamping, these connectors incorporate antifatigue design features—such as optimized spring slots and relief cuts—to ensure consistent mating force over thousands of cycles. Following stamping, each contact surface is selectively plated with a controlled gold thickness to guarantee stable electrical performance and long-term durability in EV powertrain and battery applications. As full-service OEM manufacturers, we provide turnkey solutions from custom part design and tool development to precision stamping, plating, secondary processing, and final assembly—ensuring components that meet rigorous automotive standards and performance requirements.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | High-Purity Copper (C102/C110) or Brass (H65), per customer specification |

| Gold Plating Thickness | 0.3–1.5 µm (customizable) |

| Underplate Options | Nickel (1–2 µm) or Tin (2–5 µm) |

| Packing | Anti-Static, ESD-Safe Custom Packaging |

| Delivery Time | 15–25 Days (depending on order size and complexity) |

| Size & Configuration | Fully Customizable to Drawing Specifications |

| Service | End-to-End OEM Solutions (Design, Tooling, Production, Assembly) |

| MOQ | Flexible, Based on Your Requirements |

| Connector Types | Blade, Pin, Spring-Contact, Blade-Pin Hybrid, Custom Designs Supported |

| Certification | ISO 9001, IATF 16949 |

Secondary Processing Services:

- Selective Gold Plating

Utilizes precision masking and automated plating rigs to deposit gold only on critical contact areas—minimizing precious metal usage while ensuring low contact resistance and outstanding corrosion resistance. - Nickel or Tin Underplate

Applies a uniform nickel or tin undercoat prior to gold plating to improve adhesion, prevent base-metal diffusion, and enhance wear resistance. - Precision Annealing

Controlled heat-treat cycles to relieve stamping-induced stresses and optimize spring-contact resilience, ensuring reliable mating force over extended cycles. - Laser Marking & Etching

High-resolution laser engraving for permanent part identification, date codes, or logos without compromising plating integrity or electrical performance.

Quality Assurance:

Our rigorous QA framework aligns with ISO 9001 and IATF 16949 automotive standards, ensuring each connector meets precise performance criteria:

- Dimensional Verification (CMM): Coordinate Measuring Machines confirm exact stamped geometries and tolerances to ±0.01 mm.

- Contact Resistance Testing: Automated milliohm testers validate low resistance (< 20 mΩ) under specified current loads to guarantee electrical efficiency.

- Plating Thickness Measurement: X-Ray Fluorescence (XRF) analyzers verify gold and underplate thicknesses against customer specifications.

- Fatigue & Spring-Force Testing: Custom fatigue rigs cycle connectors over 10,000+ mating operations to validate consistent contact force retention.

- Corrosion & Environmental Testing: Salt-spray (ASTM B117) and humidity chamber evaluations ensure plating adhesion and long-term resistance to oxidation.

- Surface Inspection: Automated optical scanning (AOI) detects any plating defects, burrs, or surface irregularities.

- Material Hardness & Conductivity Checks: Rockwell hardness testers and electrical conductivity meters confirm alloy integrity and performance.

Why Choose Us?

- Transparent, Factory-Direct Pricing

By controlling every step—from raw-material procurement to final assembly—we eliminate middlemen and deliver competitive costs without sacrificing quality. - Automotive-Grade Quality Governance

Backed by ISO 9001:2015 and IATF 16949 certifications, our multi-stage inspection protocol (first-article approval, in-process audits, and final acceptance) guarantees consistent precision and reliability. - Seamless End-to-End Support

From initial concept and CAD design to tool fabrication, production scheduling, and logistics management, our dedicated project managers ensure a frictionless experience and timely communication. - Dependable On-Time Delivery

With optimized production workflows and a resilient supply chain, we commit to meeting your project milestones—even under tight deadlines—so you can rely on us to keep your production on schedule.

Our Factory:

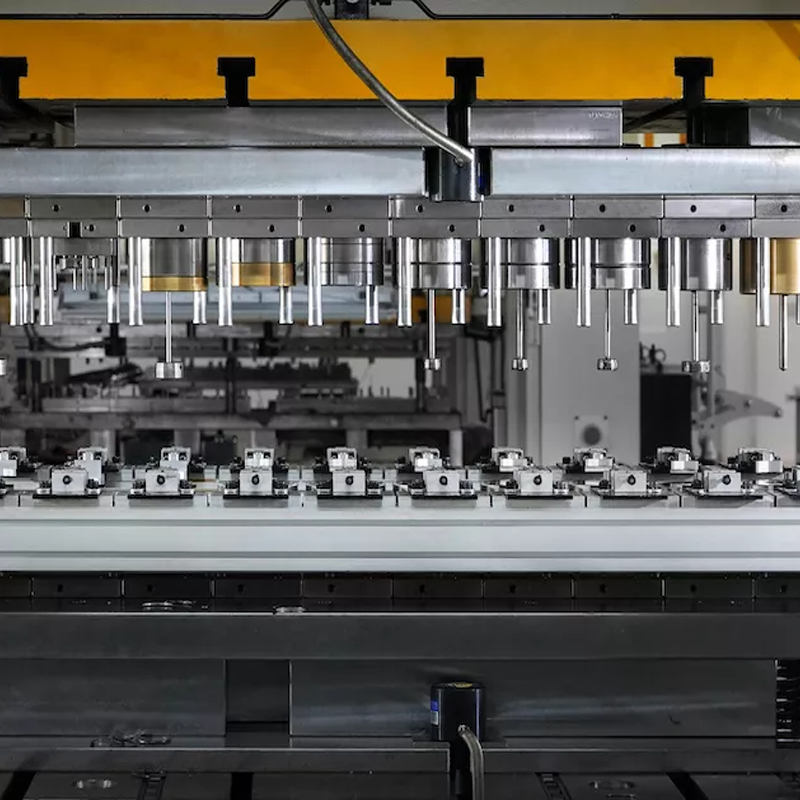

Our state-of-the-art manufacturing facility is engineered for high-precision stamping and plating:

- 45 Progressive-Die Stamping Presses (100–500 tons) configured with automated coil-feeding systems for consistent high-volume stamping and tight-tolerance part geometry.

- High-Precision CNC Machining & EDM Centers for die maintenance, progressive tool insert fabrication, and critical fixture manufacturing with ±0.005 mm accuracy.

- Selective Plating Lines equipped with robotic masking stations, automated immersion plating tanks, and real-time bath monitoring to maintain plating consistency and quality.

- Laser Marking & Cutting Stations featuring high-resolution laser heads for precise part identification and micro-etching.

- Environmental Control Systems including Class 8 cleanrooms for plating operations to minimize particulate contamination and ensure plating adhesion.

- Ultrasonic Cleaning & Baking Ovens to remove residue and finalize plating hardness.

Our dedicated QA team—armed with CMMs, XRF analyzers, fatigue testers, salt-spray chambers, optical inspection systems, and contact resistance benches—ensures that every connector leaving our facility meets the highest standards of precision, durability, and performance required for electric vehicle applications.

Reviews

There are no reviews yet.