Overview:

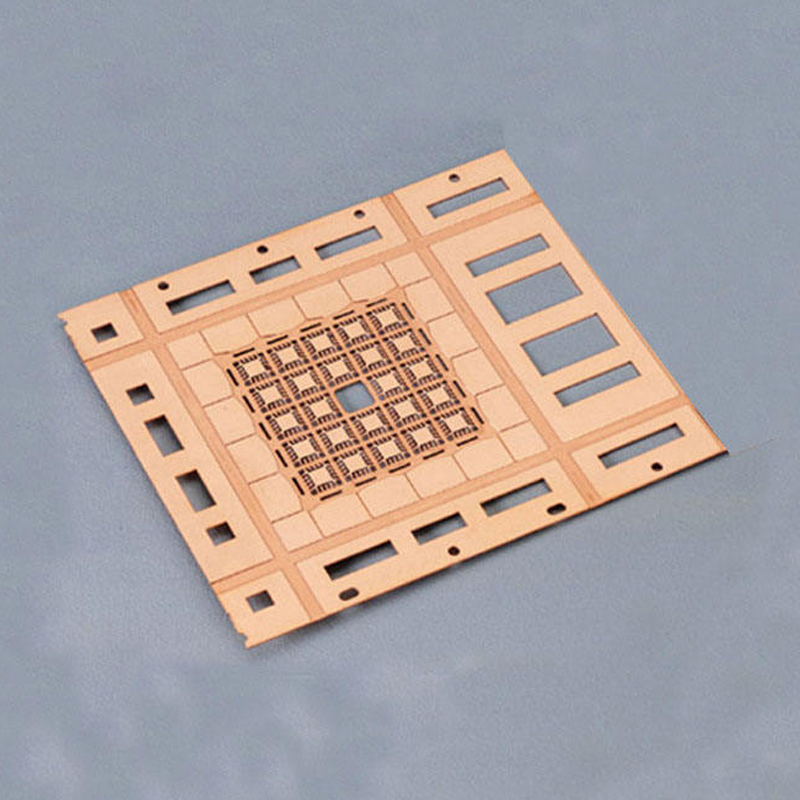

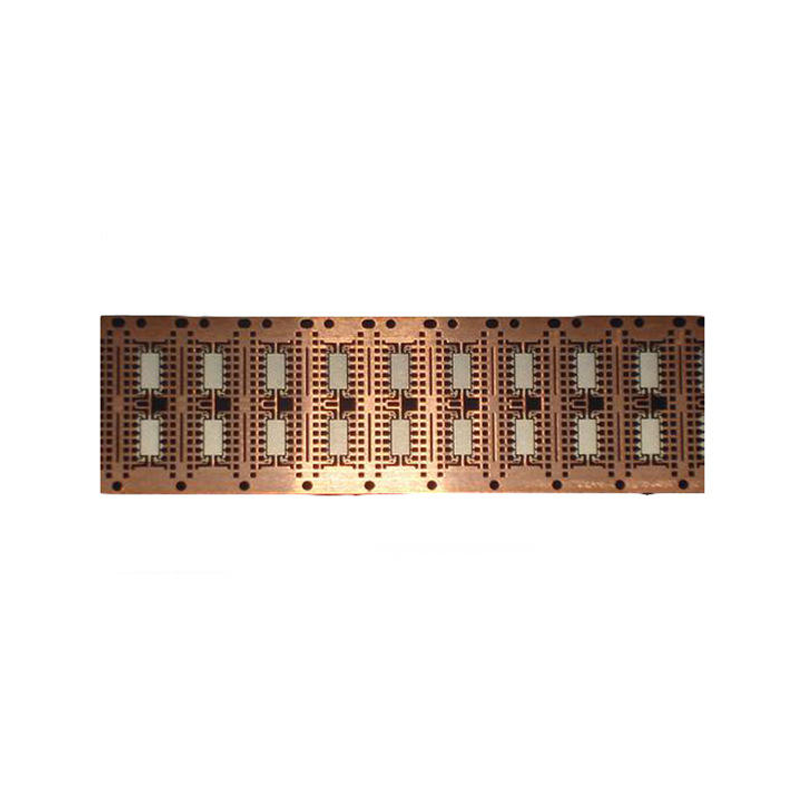

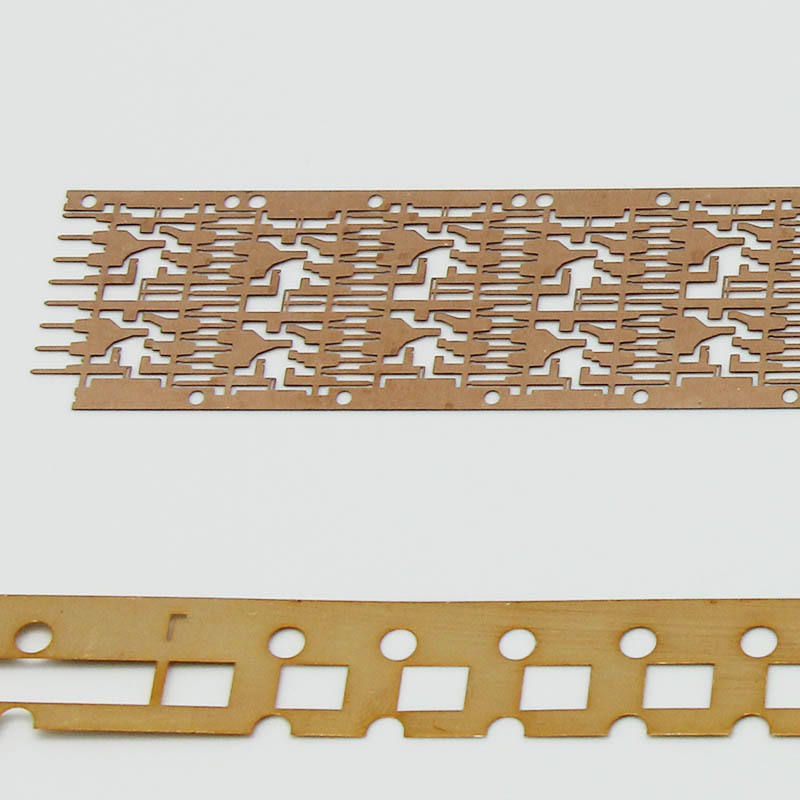

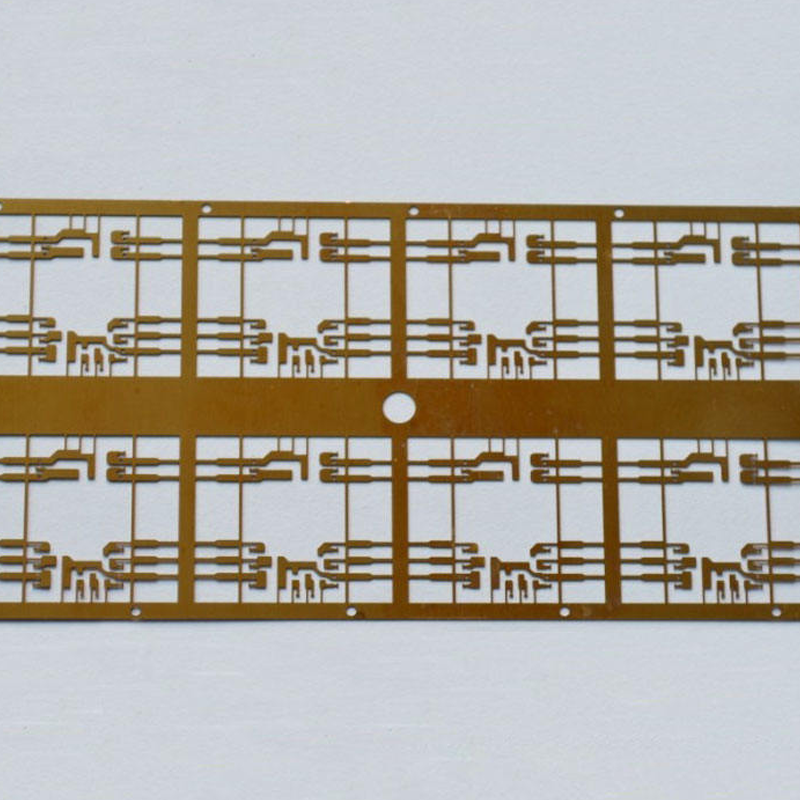

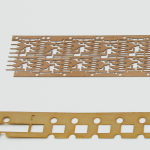

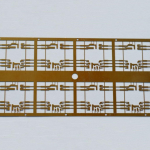

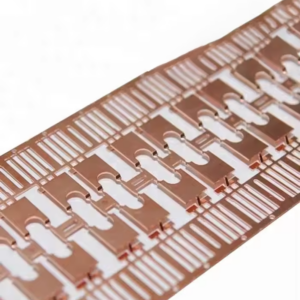

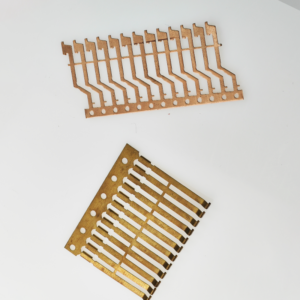

OEM Progressive Stamping Copper Alloys Lead Frames with Laser Etching offer high-precision electrical connectivity for semiconductor and electronic packaging. Manufactured from premium copper alloys via automated progressive die stamping, they ensure excellent conductivity and mechanical stability, with laser etching providing permanent, precise markings or fine-feature adjustment.

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Process | Progressive Die Stamping & Laser Etching |

| Material | Copper Alloys (C194, C151, C7025, Klfe-1, etc.) |

| Tolerance | ±0.01mm (Stamping), ±0.005mm (Etching) |

| OEM/ODM | Welcome |

| QC Control | 100% Automated Optical Inspection (AOI) |

| Standard | ISO9001, IATF16949 |

| Size & Design | Fully Customizable |

| Sample | Available |

| Plating | Optional (Tin, Silver, Nickel, Gold, etc.) |

Advantages of Our Lead Frames:

-

High-Volume Cost Efficiency: Progressive stamping enables the rapid production of complex parts in a single operation, significantly reducing unit cost for large-volume orders.

-

Superior Electrical & Thermal Performance: Premium copper alloys provide excellent conductivity and heat dissipation, which is critical for device reliability and performance.

-

Exceptional Precision & Consistency: The combination of precision stamping dies and laser etching achieves tight tolerances, fine pitches, and consistent part geometry crucial for automated assembly.

-

Design Flexibility & Integration: The process allows for complex multi-function designs (forming, coining, etching) in a single part, and laser etching can add serial numbers, logos, or adjust electrical properties.

Finishing Options:

-

Tin Plating: The most common finish, providing excellent solderability, good corrosion resistance, and cost-effectiveness for standard applications.

-

Silver Plating: Offers superior electrical conductivity and solderability, often used in high-power or high-frequency devices.

-

Nickel Plating (Underplate): Serves as a diffusion barrier between the copper substrate and final plating (like gold), enhancing durability and preventing intermigration.

-

Selective Gold Plating: Applied to specific contact areas (e.g., bond fingers) for outstanding corrosion resistance, reliable wire bonding, and low contact resistance.

-

Anti-Tarnish Treatment: An organic coating applied to bare copper surfaces to prevent oxidation during storage and handling before assembly.

Why Partner with Us?

-

Expertise in Precision Metal Stamping: We specialize in high-speed progressive stamping of intricate electronic components, ensuring your lead frames meet exacting technical and volume requirements.

-

Integrated In-House Manufacturing: Our control over the entire process chain—from tooling design and stamping to laser etching and plating—ensures quality consistency, shorter lead times, and better cost management.

-

Rigorous Quality & Traceability Systems: Adhering to IATF 16949 and ISO 9001 standards, we implement SPC (Statistical Process Control) and 100% AOI to guarantee defect-free parts. Full material and process traceability is provided.

-

Engineering-Driven Customer Support: Our technical team partners with you from the design phase (DFM analysis) through prototyping and production, ensuring optimal performance, manufacturability, and cost-efficiency for your application.

Our Factory:

Our facility is purpose-built for high-precision metal stamping and micro-processing. We house a battery of high-speed progressive stamping presses (from 25 to 300 tons) equipped with precision-grade dies manufactured on-site using CNC, Wire-EDM, and grinding centers. For secondary operations, we operate advanced laser etching/cutting systems for precision marking and feature adjustment. Our integrated plating workshop offers selective and reel-to-reel electroplating lines (Tin, Silver, Nickel, Gold). Every step is governed by stringent quality protocols under our ISO 9001 and IATF 16949 certified management system, ensuring the production of lead frames that meet the most demanding automotive and electronic industry standards.

Reviews

There are no reviews yet.