Overview:

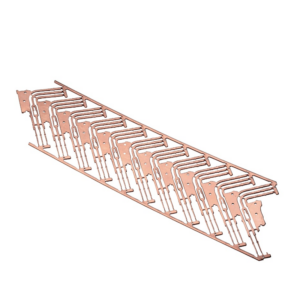

OEM Two Triode Lead Frame Processing Semiconductor Stamping Parts are engineered for precision semiconductor packaging applications, providing robust structural support and efficient electrical pathways for dual-triode devices. Manufactured from high-purity copper or alloy substrates, these lead frames are fabricated using progressive precision stamping and fine-blanking technologies, ensuring tight tolerances, high repeatability, and superior flatness for reliable assembly. Optional surface treatments such as Ag, Ni, Pd, or Au plating improve solderability, wire-bond adhesion, and corrosion resistance, making them ideal for high-performance, high-reliability semiconductor components. With fully customizable geometries, layouts, and dimensions, our OEM solutions deliver optimized thermal conductivity, low electrical resistance, and mechanical stability—tailored to the evolving demands of advanced power electronics and consumer semiconductor devices.

![]()

Characteristics:

| Parameter | Value |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Copper / Copper Alloy |

| Application | Semiconductor Packaging (Dual Triode Devices) |

| Service | Customized OEM |

| Surface Treatment | Nickel, Silver, Gold, Palladium (optional) |

| Size | Customizable |

| Tolerance | ±0.01–0.03 mm |

| MOQ | Small Orders Accepted |

| Color | Customized Finish |

| Sample | Available |

| Certifications | ISO 9001, IATF 16949, RoHS/REACH |

Surface Treatment Options:

- Nickel Plating (Ni): Provides strong solder-leach resistance and wire-bond reliability.

- Silver Plating (Ag): Offers excellent electrical conductivity and cost-effective performance.

- Gold Plating (Au): Ensures ultra-low contact resistance and long-term corrosion stability for high-reliability devices.

- Palladium Plating (Pd): Improves oxidation resistance and wire-bonding adhesion for demanding applications.

Quality Assurance:

Our QA process for OEM triode semiconductor lead frames ensures maximum precision and reliability at every step. Incoming copper/alloy materials are strictly verified for purity and conductivity. During production, CMMs (Coordinate Measuring Machines), 3D optical profilers, and surface roughness testers confirm dimensional accuracy and planarity. Electrical resistance is evaluated using micro-ohm meters, while environmental reliability is tested in thermal cycling chambers, salt-spray cabinets, and high-humidity aging systems. Each part undergoes first article inspection, in-process audits, and automated vision inspection, ensuring defect-free results. Our facility is ISO 9001:2015 and IATF 16949 certified, fully RoHS/REACH compliant, with full batch traceability for semiconductor-grade assurance.

Why Choose Us?

- Advanced Stamping Expertise – Equipped with high-speed precision stamping lines, we guarantee consistent micron-level accuracy and repeatability.

- Comprehensive OEM Solutions – From design validation and prototyping to large-scale production, we provide complete customization of materials, layouts, and plating finishes.

- Strict Quality Assurance – Certified to ISO 9001 and IATF 16949, our multi-stage testing regime ensures stable performance under the most demanding semiconductor packaging conditions.

- Reliable Supply Chain – Optimized production workflows and robust logistics management guarantee on-time delivery for both small-volume development projects and mass production orders.

Our Factory:

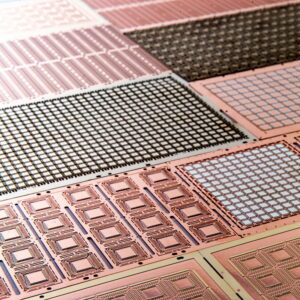

Our facility integrates 25 high-speed stamping presses (25–300 tons), precision wire EDM, fine-blanking systems, and automated welding and cleaning lines, enabling exceptional accuracy and superior part cleanliness for semiconductor lead frames. Advanced plating capabilities—including nickel, silver, gold, and palladium—ensure enhanced performance and compliance with global standards. With automated assembly support and an in-house toolroom, we deliver fast turnaround from prototype to mass production. Backed by ISO 9001 and IATF 16949 certifications, our factory combines scale, precision, and reliability to support leading-edge semiconductor packaging solutions.

Reviews

There are no reviews yet.