Overview:

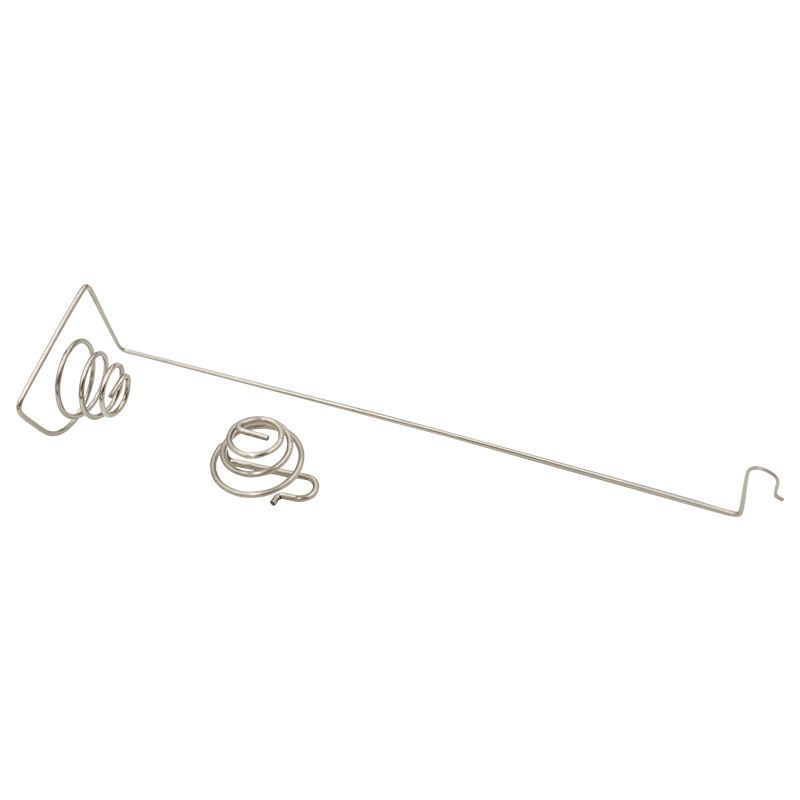

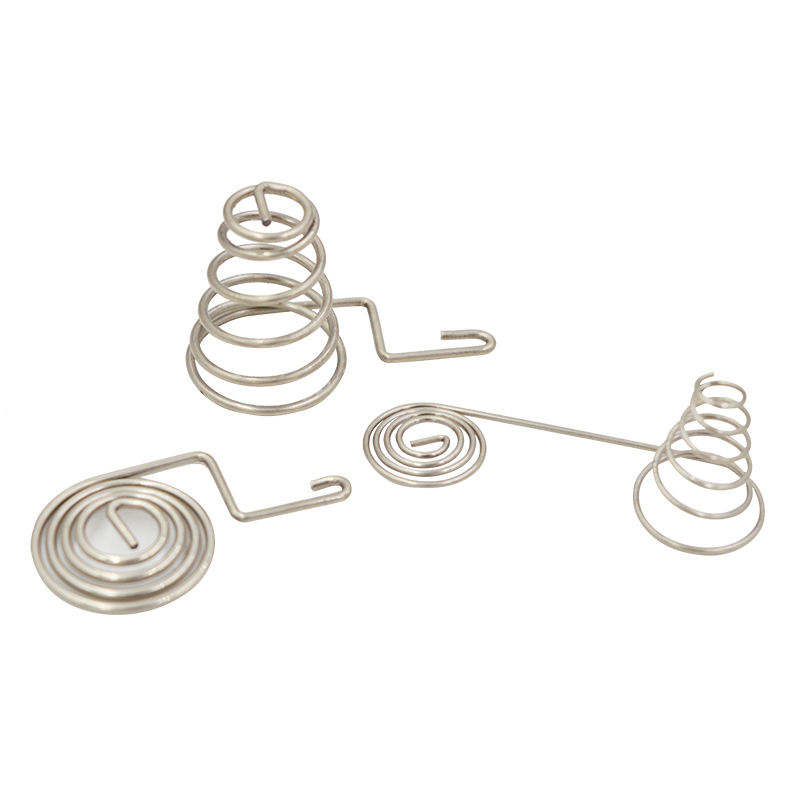

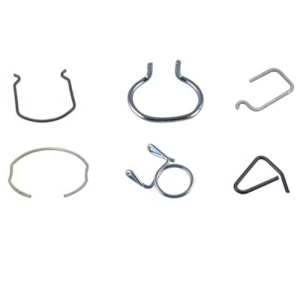

Our Personalized Wire Forming Stainless Steel Coiled Springs for Battery Contact Applications are engineered to provide reliable electrical connectivity and optimal mechanical resilience in battery assemblies. Manufactured from premium stainless steel spring wire (302/304), these springs are produced using precision CNC wire forming and controlled heat‐treatment processes to achieve exact load ratings, dimensional accuracy, and excellent corrosion resistance. As a leading OEM supplier, we offer fully customizable spring geometries, wire diameters, and plating options to meet the specific requirements of your battery contact designs, ensuring superior performance and long service life.

Specifications:

| Parameter | Details |

|---|---|

| Material | Stainless Steel 302 or 304 Spring Wire |

| Manufacturing Process | CNC Wire Forming, Precision Bending, Heat Treatment |

| Wire Diameter | 0.2 mm – 2.0 mm (custom sizes available) |

| Outer Coil Diameter | 1.0 mm – 10 mm (per design requirements) |

| Free Length | 2 mm – 50 mm (customizable) |

| Load Rating | 0.05 N – 50 N (configured via coil count and wire diameter) |

| Tolerance | ±0.005 in (±0.13 mm) or per customer specification |

| Surface Finish | Passivation, Tin Plating, Nickel Plating, or Custom Coating |

| Certification | ISO 9001:2015, IATF 16949, RoHS |

| Sample Availability | Prototypes delivered within 7–14 days |

| MOQ | According to your requirement |

| Packaging | Bulk or individual, anti‐static trays available |

| Operating Temperature | –40 °C to +125 °C |

| Lead Time | 15–30 days (depending on volume and complexity) |

Surface Treatment Options:

- Tin Plating: Enhances solderability and maintains low contact resistance in battery interfaces.

- Nickel Plating: Provides superior corrosion resistance and electrical conductivity for long‐term reliability.

- Passivation: Creates a protective oxide layer on stainless steel to prevent surface corrosion without affecting conductivity.

- Custom Coating: Apply specialized coatings (e.g., gold flash) to meet unique contact resistance or environmental requirements.

Quality Control:

Our stringent quality assurance program complies with ISO 9001 and IATF 16949 standards. We conduct in‐process inspections using optical comparators and high‐precision CMMs to verify spring geometry and dimensions. Electrical contact resistance is measured with microvoltmeters, while mechanical performance—load vs. deflection—is validated on automated spring testers. Corrosion resistance is confirmed via salt spray testing (ASTM B117), and material composition is verified by XRF spectrometry. Every batch undergoes 100% visual and functional inspection before shipment.

Factory Overview:

Equipped with state‐of‐the‐art CNC wire‐forming machines, precision bending stations, and controlled‐atmosphere heat‐treatment ovens, our facility delivers springs with micron‐level accuracy and consistent performance. We also maintain automated shot‐peening and plating lines for enhanced fatigue life and corrosion protection. With fully integrated SPC software and a certified ISO 9001/IATF 16949 quality management system, our production lines ensure high throughput while maintaining exceptional precision and reliability for all your battery contact spring requirements.

Reviews

There are no reviews yet.