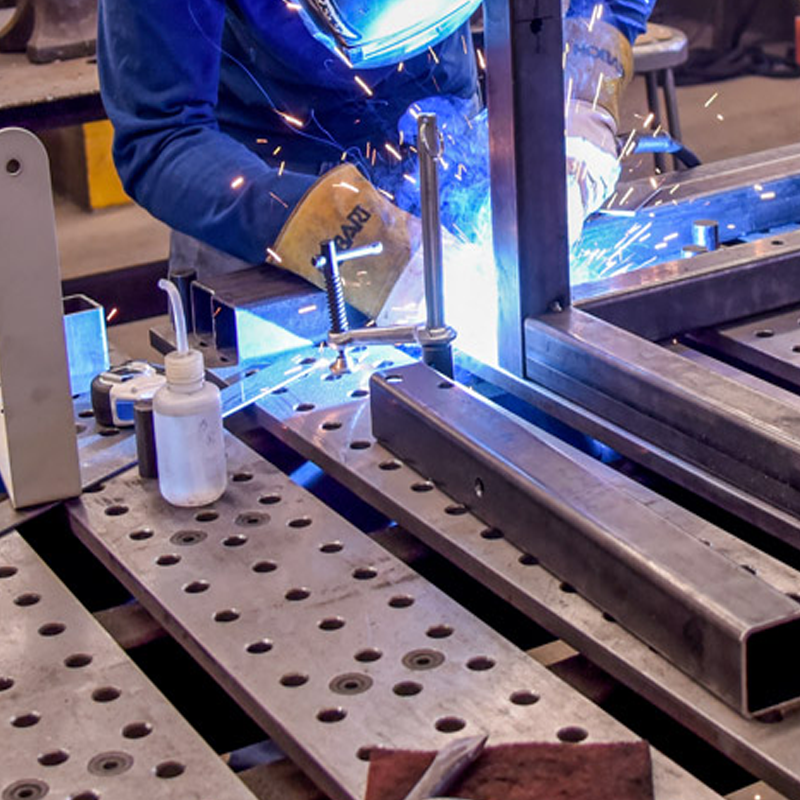

Welding defects are one of the most common challenges manufacturers face, and they can have significant impacts on product performance, safety, and costs. Whether you are producing high-precision components for automotive, aerospace, or industrial applications, understanding and preventing welding defects is critical. At Topmetalstamping, we are dedicated to providing our clients with the highest-quality products through efficient welding processes and attention to detail. In this blog, we will explore the most common welding defects, their causes, and how we ensure precision and consistency in every weld.

Why Understanding Welding Defects Matters

As a manufacturing partner committed to high-precision and OEM service, we know that a single welding defect can cause delays, increase costs, and, in some cases, lead to failure in critical applications. For customers like Sarah, an automotive manufacturer in the U.S., ensuring that every weld is flawless is non-negotiable. She relies on our expertise to meet demanding quality standards without delay. This is why we take the time to meticulously control every variable involved in welding. Let’s take a closer look at some of the most common welding defects and how we at Topmetalstamping prevent them in our manufacturing process.

Common Welding Defects and How to Prevent Them

Welding defects typically fall into three major categories: issues with the weld’s appearance or shape, problems with internal structure or fusion, and post-welding part deformation. Below, we’ll discuss each in detail and explore how they can be prevented.

1. Poor Weld Formation

Poor weld formation is a visible defect that often results from improper welding parameters or operator technique. Common issues include:

- Uneven width

- Excessive reinforcement (too much weld metal)

- Undercutting (grooves on the base metal)

- Rough or inconsistent surface

At Topmetalstamping, we pay close attention to the laser power, welding speed, and focus to prevent these issues. Our high-precision equipment, combined with the experience of our skilled welders, ensures that every weld meets strict specifications, resulting in smooth, visually consistent, and structurally sound welds.

We also use advanced monitoring systems to track every weld in real-time. This allows us to adjust parameters immediately to avoid poor formation, ensuring that every product, whether it’s for an automotive frame or a medical device, is perfectly formed.

2. Lack of Fusion

Lack of fusion occurs when the weld metal does not bond properly with the base metal. This can lead to weak spots that compromise the strength of the entire part. The most common causes are insufficient heat input, incorrect laser focus, or inconsistent travel speed.

To avoid this issue, we ensure precise control of heat input and use optimized welding techniques. For every job, we generate a detailed weld procedure specification (WPS) to guide our operators, guaranteeing the right settings for every material. With our state-of-the-art laser welding systems and robust quality control checks, we can guarantee perfect fusion in every weld, providing our clients with high-strength parts that meet the most demanding requirements.

3. Porosity

Porosity refers to small gas bubbles trapped inside the weld, which can significantly weaken the structure. This defect is typically caused by gas contamination, moisture on the material surface, or incorrect shielding gas.

At Topmetalstamping, we take extra steps to clean materials thoroughly before welding, ensuring that there is no moisture or contamination present. We also use high-quality shielding gases to protect the weld pool and prevent porosity. As part of our one-stop service, we manage the entire process—from material selection to final inspection—ensuring that every weld is free from defects like porosity.

4. Cracking

Cracking is one of the most severe welding defects, as it can compromise the entire integrity of the part. Cracks can occur in the weld metal or the base metal near the weld and often result from high-stress areas or improper cooling rates.

To prevent cracking, we control the cooling rate and welding sequence to ensure that heat is distributed evenly across the part. Additionally, we use pre-heat treatment and post-weld heat treatment to reduce the risk of thermal stress, ensuring that all parts—whether used in aerospace applications or industrial machinery—are structurally sound and free from cracks.

Welding Defects in Specific Processes: SMAW vs. Laser Welding

While welding is a versatile process, it’s essential to understand the defects specific to each type of welding. For example, Shielded Metal Arc Welding (SMAW) is prone to defects like slag inclusions and spatter, which can create weak points in the weld. To prevent this, we maintain proper amperage settings and regular cleaning between passes.

On the other hand, laser welding, which is frequently used at Topmetalstamping for high-precision applications, faces unique challenges, such as incorrect fusion depth and deformation due to heat input. To combat these, we carefully control the laser power, focus, and travel speed to ensure that the weld penetrates the base material perfectly and that deformation is minimized.

How Topmetalstamping Ensures Quality Control in Welding

At Topmetalstamping, quality control is integral to our manufacturing process. We adhere to strict standards such as ISO 9001 and ISO 13485 to ensure that every weld is consistent and meets the highest quality benchmarks. This is particularly critical for industries like medical devices and automotive parts, where precision is paramount.

In addition to certification standards, we also provide OEM services that allow us to customize every aspect of the welding process to meet our client’s specific needs. Whether it’s adjusting parameters for a complex part or providing additional services like post-weld inspections, we ensure that every part is manufactured to the highest standards, delivering optimal results every time.

Preventing Welding Defects: The Role of a Weld Procedure Specification (WPS)

To ensure the best quality, we create a Weld Procedure Specification (WPS) for every project. This document acts as a blueprint, specifying the correct materials, temperatures, welding techniques, and other parameters for each part. By following a detailed WPS, we minimize the risk of defects and ensure that the same level of precision is maintained from start to finish.

Conclusion: The Importance of Preventing Welding Defects

Welding defects can be costly, both in terms of time and money. At Topmetalstamping, we focus on prevention to eliminate the possibility of defects, ensuring that every part we produce meets the highest standards of quality and performance. Through our custom services, high-precision welding techniques, and advanced quality control systems, we help our clients avoid costly mistakes and achieve the best possible results.

For any project, whether it’s for automotive manufacturing, medical device production, or industrial equipment, working with a trusted manufacturer like Topmetalstamping can help you avoid welding defects and get your parts to market faster and more reliably. Ready to start your next project? Contact us today to learn how we can provide one-stop service for all your welding and manufacturing needs.